This article is an excerpt from Episode 9 of Alchemy-Spetec's podcast The Injection Connection, featuring Charlie Lerman "The Grout Geek". Charlie is Director of Technical Services - Leak Seal® Division at Alchemy-Spetec. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this excerpt is posted at the bottom of the article.)

This article is an excerpt from Episode 9 of Alchemy-Spetec's podcast The Injection Connection, featuring Charlie Lerman "The Grout Geek". Charlie is Director of Technical Services - Leak Seal® Division at Alchemy-Spetec. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this excerpt is posted at the bottom of the article.)

Jim Spiegel: I always say to people is you should account for some exploration time. Everybody wants to go quick into, "What are the coverage rates, how many linear feet can I do in a day, how many people do I need, what’s the size of the crew, how many man hours as a prevailing wage." But I like to tell people let’s put half a day, even up to a full day depending on the job, into exploration. Would you agree with that?

Charlie Lerman: 100%. Exploratory grouting is the way to go. And on smaller jobs a lot of times, that’s going to knock out the whole job anyway. But when you get to those larger jobs for curtain grouting and crack injection, just having that day to look at and say, “These are the parameters. We think we’re going to be between this and this mark and by this procedure.” You go out there and you find - well, did I fall in that, where did I fall in that and if so, how are we going to adjust out the rest of the job now that we know some specifics there? But until you get out there, it’s really all theory. I’m in tons of meetings where there’s all this theory crafting and people talk about this stuff. And while this theory crafting is great and we need to do it to wrap our heads around the situation, it comes down to it when you’re actually injecting, you don’t have precise control over your liquid, you don’t know exactly where it went. You can only see the result and make assumptions. Whatever I pictured in my mind is what I can say happened in there, but until we rip that open, which almost never happens, you don’t know exactly how it went inside. So again, all that theory and stuff, that’s all great to talk about. But until you put the wheels on the road and see what happens, you just don’t know. I’ve seen stuff where you just start scratching your head - how could this be going that way? But it does and you figure it out and work through it.

Listen to the audio version of this excerpt...

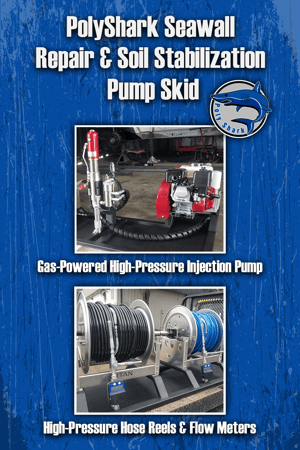

Single-Component Geotech Pump Skid

Single-Component Geotech Pump Skid

This post is part of the Alchemy-Spetec

This post is part of the Alchemy-Spetec

This article is an excerpt from

This article is an excerpt from

We understand that chemical grouting is often not the primary focus of a construction or repair job, but a water leak can often bring the rest of the job to a screeching halt until it is sealed. Job costs then start to pile up, production or facility services stay shut down as time drags on, sometimes tempers begin to flare. Sound familiar?

We understand that chemical grouting is often not the primary focus of a construction or repair job, but a water leak can often bring the rest of the job to a screeching halt until it is sealed. Job costs then start to pile up, production or facility services stay shut down as time drags on, sometimes tempers begin to flare. Sound familiar?

I often get asked about pre-drilling for crack injection. Pre-drilling is the practice of putting all the ports in position before injecting anything. This preparation procedure can often be very time efficient. Think of this an assembly line approach. Pre-drilling is often done when there is “shut-down” period on a job with a limited time to get the work done. You’ll encounter these types of jobs in subway systems, for example, when the work needs to be done while the trains aren’t running. That’s just one specific example, but you get the idea.

I often get asked about pre-drilling for crack injection. Pre-drilling is the practice of putting all the ports in position before injecting anything. This preparation procedure can often be very time efficient. Think of this an assembly line approach. Pre-drilling is often done when there is “shut-down” period on a job with a limited time to get the work done. You’ll encounter these types of jobs in subway systems, for example, when the work needs to be done while the trains aren’t running. That’s just one specific example, but you get the idea.

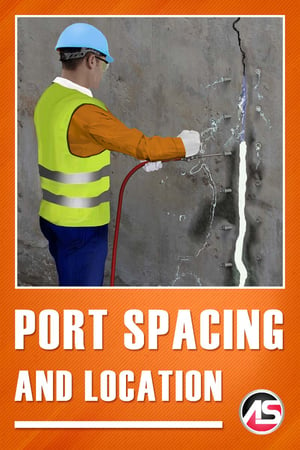

Port spacing in the case of crack injection has nothing to do with the distance between a port in Miami and a port in Jamaica. In this case, we are simply discussing how far apart to place your injection ports. This is not a fixed distance, as proper port spacing varies depending on site conditions.

Port spacing in the case of crack injection has nothing to do with the distance between a port in Miami and a port in Jamaica. In this case, we are simply discussing how far apart to place your injection ports. This is not a fixed distance, as proper port spacing varies depending on site conditions.

This article is an excerpt from

This article is an excerpt from

As we stated in a previous blog post,

As we stated in a previous blog post,