You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

You've now gained valuable insights into the world of driveway concrete leveling, understanding the issues caused by sunken slabs, the options for repair, and how to choose the right path for your home. As you ponder your next steps, consider this important aspect: the expertise and assistance you need to get your driveway back to its prime condition.

Why Expertise Matters

Concrete leveling, whether using polyurethane foam or other methods, requires precision and experience. It's not a DIY project and finding the right contractor can make all the difference. You want someone who understands the intricacies of the process, can assess your specific situation, and execute the repair flawlessly.

Alchatek: Your Trusted Partner

Alchatek, a leading manufacturer in the construction industry, specializes in innovative solutions for concrete leveling and repair. With a strong commitment to excellence and a drive for innovation, Alchatek has a track record of providing high-quality products and equipping contractors with the tools and knowledge they need.

How Alchatek Can Help You

Whether you're looking for more information, guidance on your project, or a referral to a qualified contractor, Alchatek is here to assist you. Our expert team understands the nuances of driveway concrete leveling and can connect you with experienced professionals who can get the job done right.

Contact Alchatek Today

Don't let your sunken driveway slabs continue to be a headache. Take action and reach out to Alchatek for the support and expertise you need. Your driveway deserves the best, and Alchatek can help you achieve it.

Call 404-618-0438 or fill out this form to contact Alchatek today!

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

When hiring a company to level sunken driveway concrete with polyurethane, homeowners should look for certain qualifications and ask key questions. This helps verify the contractor has the right expertise to tackle the project. By selecting a reliable, experienced professional, homeowners can feel confident about the outcome.

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

When it comes to concrete leveling, homeowners may wonder whether polyurethane or mudjacking is the better method. Both can lift and stabilize sunken slabs without having to demolish and replace the driveway. However, there are some key differences between these two common repair techniques.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

Should you repair sunken slabs or replace the driveway completely? There are pros and cons to each approach.

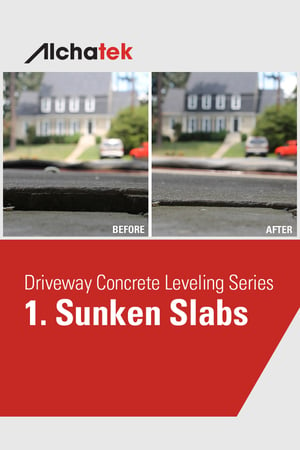

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

It's a scene that many homeowners dread: glancing out the window one day to discover large sunken areas in your once-smooth concrete driveway. These uneven sagging sections seem to appear out of nowhere, but in reality, are the result of a very common problem.

Unstable soils present significant challenges in civil engineering projects. Whether caused by erosion, improper compaction, freeze-thaw action, or decay of buried organic matter, loose and shifting soils undermine structural integrity. Together, these mechanisms prevent soil from remaining firmly in place. This necessitates methods to stabilize and strengthen the matrix. Geotechnical engineers must find solutions to reinforce the substrate and restore load-bearing capacity.

Unstable soils present significant challenges in civil engineering projects. Whether caused by erosion, improper compaction, freeze-thaw action, or decay of buried organic matter, loose and shifting soils undermine structural integrity. Together, these mechanisms prevent soil from remaining firmly in place. This necessitates methods to stabilize and strengthen the matrix. Geotechnical engineers must find solutions to reinforce the substrate and restore load-bearing capacity.

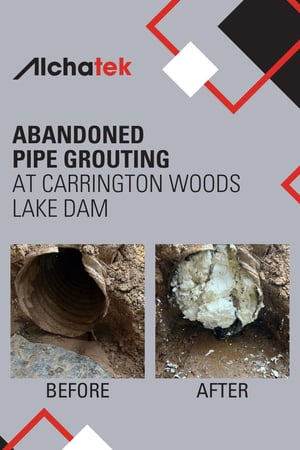

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

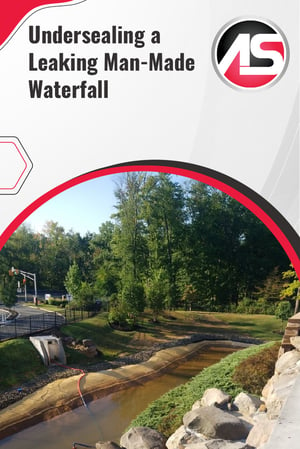

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

We've created a video for a question we get asked a lot: "How do I make single-component samples?" A lot of people want samples, sales teams love samples, homeowners love them because it’s actually something they can put in their hands on. They can really help close a deal.

We've created a video for a question we get asked a lot: "How do I make single-component samples?" A lot of people want samples, sales teams love samples, homeowners love them because it’s actually something they can put in their hands on. They can really help close a deal.