I think you’ll agree with me when I say that, as a slab lifting contractor, you can never have too many leads. While there may be dozens of methods available, there are three very effective resources our customers strategically use to land new slab lifting projects on a regular basis. Let’s get started.

I think you’ll agree with me when I say that, as a slab lifting contractor, you can never have too many leads. While there may be dozens of methods available, there are three very effective resources our customers strategically use to land new slab lifting projects on a regular basis. Let’s get started.

HomeAdvisor

HomeAdvisor can be a lead machine for residential slab lifting contractors. HomeAdvisor's online and TV marketing efforts draw in homeowners looking for local contractors of all kinds. You pay a membership fee, set a lead budget, and they feed you concrete leveling opportunities. But it doesn’t stop there. Here are some tips that can help you capitalize on those leads:

- Call the homeowner immediately: These leads go to multiple contractors so you need to be among the first to book an appointment.

- Pick specific zip codes: You can call HomeAdvisor and limit your advertising to higher-income zip codes, zip codes closest to your business, etc. Take some time to think through the reasons for targeting specific areas. For example, higher-income homeowners tend to care more about quality than price, jobs near your business reduce travel costs, and so on.

- Dispute bad leads: Some leads will come in that aren’t relevant. For example, the homeowner didn't realize they were choosing the wrong job type category, or they just wanted to ask some questions but did not actually have a project available. You can dispute these types of leads via HomeAdvisor's website or by calling their customer service line.

Google Ads

Google is the most popular search engine in the world. Our top customers have learned to leverage Google's massive user base through implementing strategic Google Ads campaigns. They use Google Ads to target local people who are searching for specific keywords such as "concrete leveling contractor near me" or "sinking driveway repair", etc. This means you can continually refine your parameters so that the most relevant leads end up on your landing page.

It's important to design a custom landing page for your Google Ads campaign, encouraging the visitor to download a brochure for more information. Your brochure download process should require the lead to enter their contact info. Some people recommend excluding website navigation menus on these pages, effectively requiring the visitor to download the brochure. In this way, you capture contact info from all types of visitors - even those who are not ready to buy yet but are in the information gathering stage. These types of visitors would otherwise scour a conventional website, take notes, and then continue searching without ever sharing their contact info. If you need someone to create your Google Ads campaign and/or landing page, we can put you in contact with experienced freelancers.

This next section is excerpted from our brochure, Marketing Your Contracting Business. (The brochure download link is at the bottom of this article.)

Blogging for Leads

Cast a Wide Net with a Lot of Posts

The more pages you have on your website, the more chances there are for someone to find it when searching a specific phrase or term. Search engines are scanning your page names, heading text, and page text when someone types in a term or phrase to see if there are any matches. So, it’s in your best interest to have as many pages full of relevant content as you can. A blog is a perfect way to accomplish that goal.

Say, for example, that you are a slab lifting contractor in San Pedro, California. You can write up case studies of jobs you’ve performed in your area. Make sure your blog titles include terms people will likely search for. For example, a post about a warehouse floor job could be titled, “Warehouse Floor Slab Lift in San Pedro”. You get the idea.

Share Your Knowledge and Build Trust

You can also use a blog as a way to share your knowledge and experience with potential customers who are looking for answers. Take some time to consider all that you’ve learned over the years and jot down ideas for blog posts that potential customers may find helpful. In addition to case studies, you can write posts instructing people how to spot problems on their property, comparing your repair costs to the costs of replacing a structure, educating people about the materials you use, etc.

You can get quite a few ideas by browsing the posts on our blog. While our articles are aimed more at contractors than property owners, you’ll still find many useful subjects to get your brainstorming started. The more useful knowledge you share, the more trust you can build with potential customers. People are much more likely to buy a service from a known expert than from a complete stranger.

Offer More Value in Exchange for Contact Info

Driving up web traffic is a good thing. Establishing yourself as an authority by creating useful content is also very helpful. If you just do those two things, you should get more people calling you and filling out the contact form on your website. But if you REALLY want to jumpstart the leads, you need to offer something of value in exchange for your reader’s contact info. At the end of every article, include a link to a relevant brochure – or something else of value – and ask for their contact info in exchange. For an example, see the form download button at the bottom of this article.

The Gift That Keeps on Giving

The great thing about a blog post with a lead capture form at the end is that, once you set it up – it’s there forever. We still get leads from blog posts we put up years ago. If you consistently write articles, you can create a compounding effect with more and more leads coming in each month.

Concrete is the most common building material in the world. While it has high compressive strength, it does not have much tensile strength. It is only since about 1910 that rebar has been specified. Reinforced concrete can and does still crack. So does that matter? Yes, most of the time it does matter.

Concrete is the most common building material in the world. While it has high compressive strength, it does not have much tensile strength. It is only since about 1910 that rebar has been specified. Reinforced concrete can and does still crack. So does that matter? Yes, most of the time it does matter.

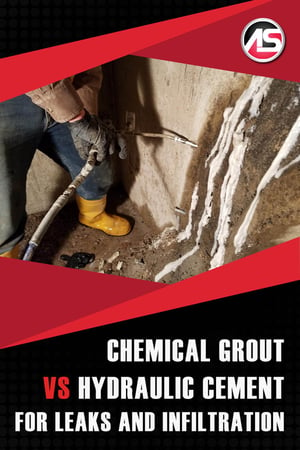

In this post, I’m going to personally review two popular methods used to handle water leaks and infiltration. Both hydraulic cement and chemical polyurethane grouts are used in civil applications such as sewer pipe rehabilitation, tunnel or shaft construction, sealing leaking cracks in concrete structures, permeating soil to control the flow of groundwater, filling voids to stabilize soil, and handling common inflow and infiltration issues found all over the world.

In this post, I’m going to personally review two popular methods used to handle water leaks and infiltration. Both hydraulic cement and chemical polyurethane grouts are used in civil applications such as sewer pipe rehabilitation, tunnel or shaft construction, sealing leaking cracks in concrete structures, permeating soil to control the flow of groundwater, filling voids to stabilize soil, and handling common inflow and infiltration issues found all over the world.

Lifting a settled bridge approach slab with

Lifting a settled bridge approach slab with

Sealing Steam Leaks with Polyurethane

Sealing Steam Leaks with Polyurethane

I was a Machinist Mate in the Navy and thus almost all of my training was mechanically focused. One class I had was Electrical Theory for Mechanics. The quick summation by the Senior Chief instructor for it was "Electricity is magic and when the smoke comes out the show is over." Being on a submarine it was deemed a good thing to keep water and electricity separate. My first time ever using polyurethane chemical grouts was on a group of sixteen conduits entering a below-grade mechanical room. While electricians may understand the "magic" of electricity they often fall short as waterproofers. Combined with the fact the numerous electrical cables coming through a conduit can be notoriously hard to waterproof and it is a recipe for leaks and electrical problems. In this post, I'll share step-by-step instructions, along with a couple of photos from a recent job one of our customers completed in a San Francisco condo complex.

I was a Machinist Mate in the Navy and thus almost all of my training was mechanically focused. One class I had was Electrical Theory for Mechanics. The quick summation by the Senior Chief instructor for it was "Electricity is magic and when the smoke comes out the show is over." Being on a submarine it was deemed a good thing to keep water and electricity separate. My first time ever using polyurethane chemical grouts was on a group of sixteen conduits entering a below-grade mechanical room. While electricians may understand the "magic" of electricity they often fall short as waterproofers. Combined with the fact the numerous electrical cables coming through a conduit can be notoriously hard to waterproof and it is a recipe for leaks and electrical problems. In this post, I'll share step-by-step instructions, along with a couple of photos from a recent job one of our customers completed in a San Francisco condo complex.

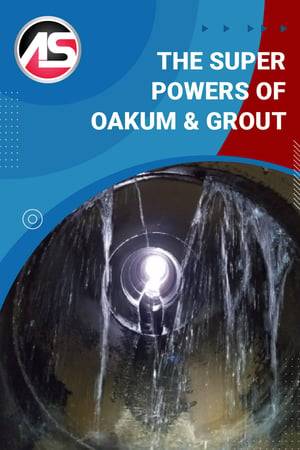

Sealing Leaks in Concrete with Polyurethane

Sealing Leaks in Concrete with Polyurethane

Alchemy-Spetec's

Alchemy-Spetec's