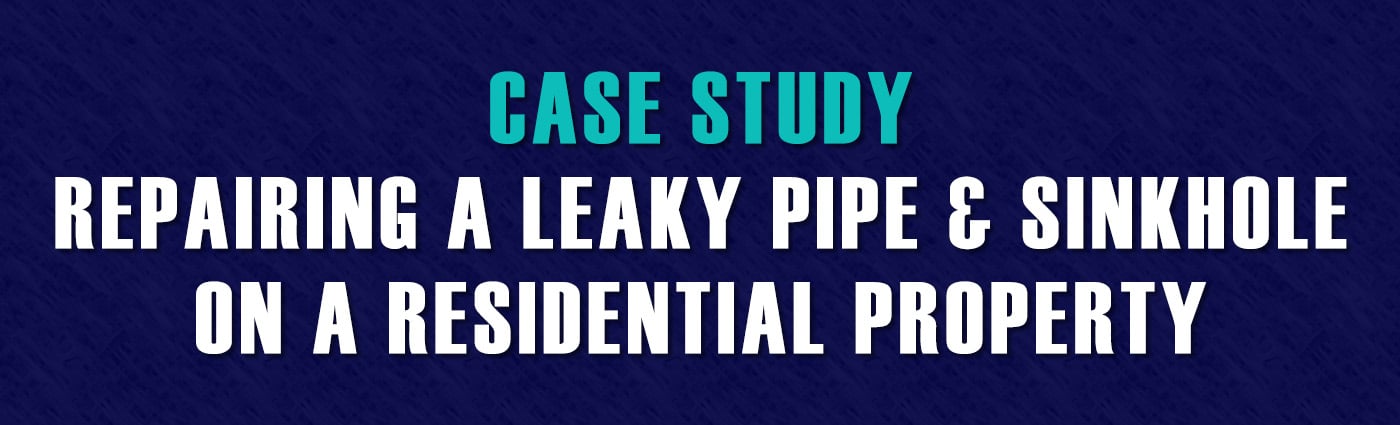

In the city limits of Atlanta, a couple was surprised to see a sinkhole forming in their home’s front yard. They became quite alarmed as within just a few weeks it swallowed their sidewalk and a decent portion of the property in front of the home. They notified the city.

After the City of Atlanta quickly got involved, some investigation revealed an old brick storm sewer running approximately 25-30 feet under the front of the property. Across the country, there is lots of brick infrastructure that’s still in service and in some cases over 100 years old. These outdated structures suffer from infiltration of groundwater which often erodes soil, as well as causes subsidence above. In this case, cameras revealed that several bricks had become dislodged, creating a pathway for soil and groundwater to get in. The end result was a rapidly forming sinkhole.

The City of Atlanta was already consulting with Alchemy Spetec on some other projects, so they asked us to take a look. After reviewing the available information and making a site visit, it was determined that a multi-step plan would need to be undertaken to seal the pipe and reestablish soil compaction.

Powerful Polymers

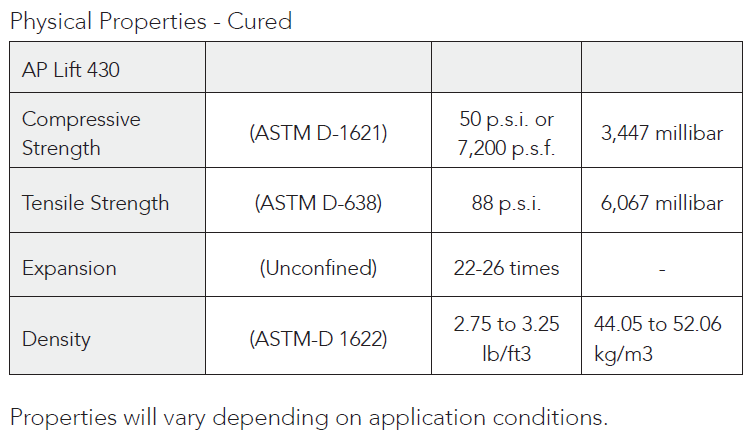

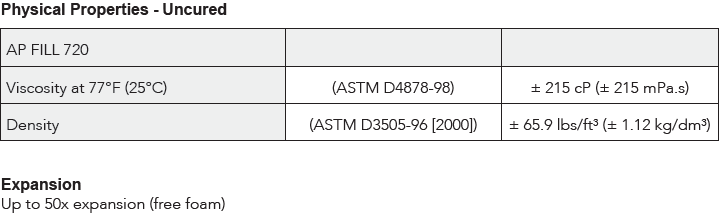

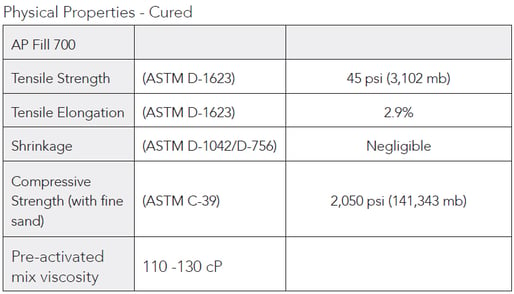

The single-component polyurethane AP Fill 700 was selected for the sealing of the pipe and for the compaction grouting of the above soils. AP Lift 430 would be kept on standby in case further grouting was required to stabilize under the home foundation itself. As it turns out, this was indeed the case.

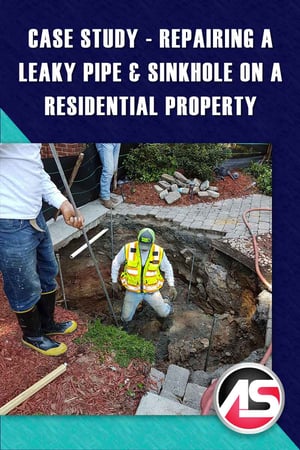

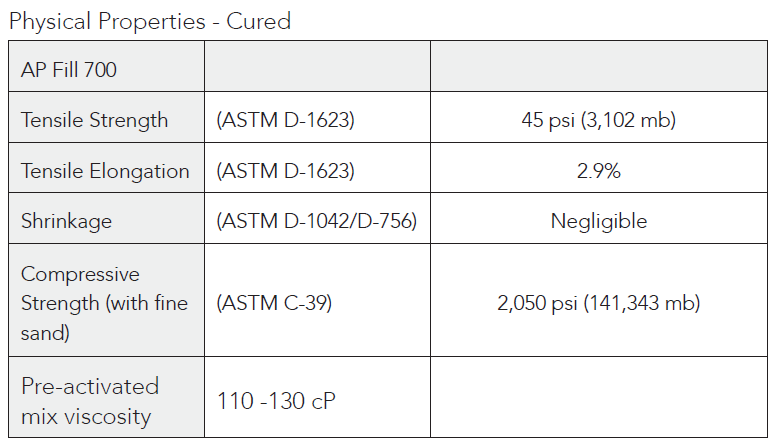

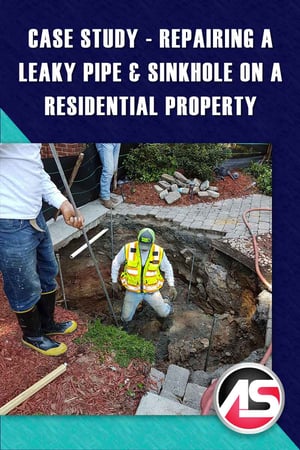

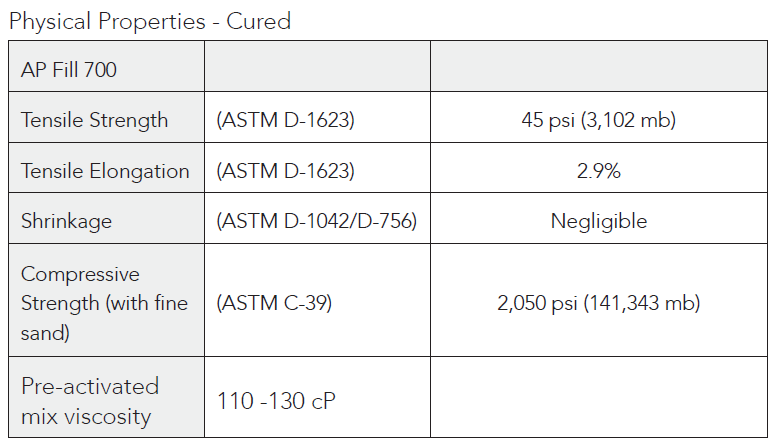

- AP Fill 700 has an adjustable set time and is highly expansive. It works in wet environments, perfect for this project. It can permeate loose soils and gravel and achieve compressive strengths in excess of 1000 psi.

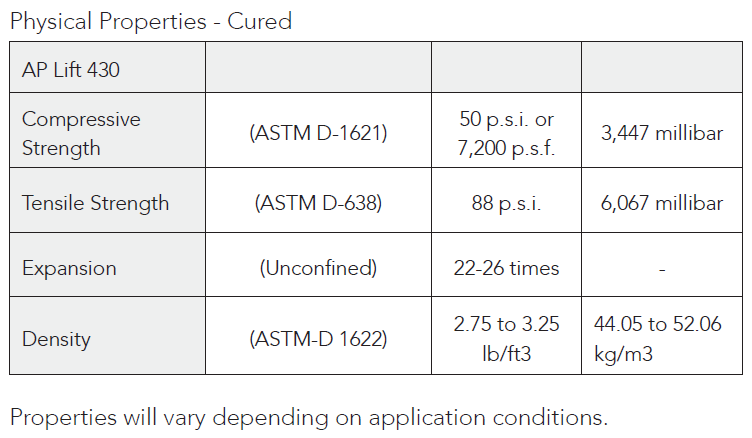

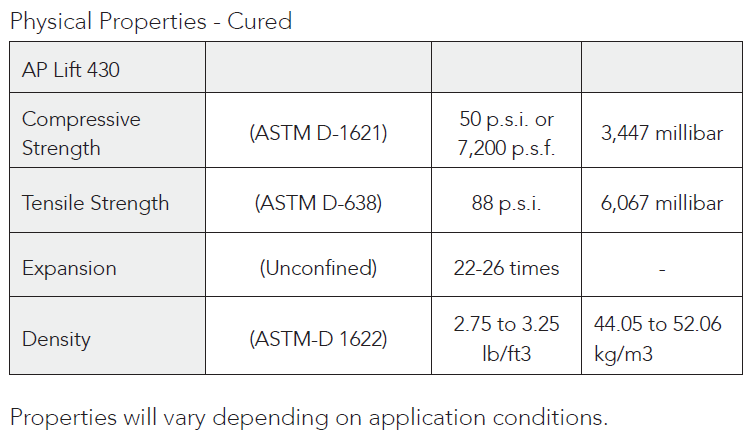

- AP Lift 430 is fast and expands 24 times its original volume. It is strong and can support 7,000 lbs per square foot.

- Both products are NSF ANSI 61 approved as safe for potable water contact. This certification provides reassurance that these products will not leach any chemicals out into the soil.

Painless Procedures

As previously mentioned, there were several steps that had to be undertaken to complete this project. First, the bricks that had become dislodged were reaffixed back into place. Once that breach was sealed, AP Fill 700 was injected through the pipe walls in multiple areas around the breach. AP Fill 700 reacts when it contacts moisture and there was no lack of that at 25 feet deep. Regardless, twin streaming through an F-Valve Assembly was implemented to ensure a good resin/water mix. This approach rapidly filled all of the voids surrounding the pipe and also sealed several other small areas of weeping water infiltration.

The second step was to fill the sinkhole with loose dirt and gravel and then permeate that with AP Fill 700 to squeeze the soil and lock all of the backfill together. Half-inch injection pipes were installed down to the top of the pipe, then soil and gravel were backfilled to the surface. Once the backfill was in place, AP Fill 700 was injected and the probes were slowly extracted to insure a uniform measure of polymer throughout the soil column. When this is done in a grid pattern, the result is a lot of increased compaction and bearing capacity.

Once the sinkhole was repaired, concern remained about loss of soil compaction under the foundation of the home. The steps leading up to the front porch had settled away from the home indicating further bad soil was likely the case.

Alchemy-Spetec is a dealer for Pagani, a dynamic cone penetrometer (DCP) manufacturer out of Italy. We brought our unit out to the property and did 6 penetrometer tests across the front of the home next to the foundation. Four of the six tests revealed weight of hammer (WOH) readings which basically means zero compaction. The soil could not even support the weight of our machine. The city was on site to see the tests and immediately approved the compaction grouting beneath the front foundation. This is where the AP Lift 430 came into play.

Half-inch injection probes were installed across the entire front of the home next to the foundation. Probes were installed down to 8 feet which is where the soil became much stronger. AP Lift 430 was injected while the crew slowly extracted the probes - until lift was observed on the home. When lift was detected, the grouting ceased. This process was repeated across the entire front of the home on 4-foot spacing.

After the compaction under the footing was reestablished, the front steps that had settled away from the house were lifted back into place using AP Fill 430.

Rapid Results

The job was completed quickly without any excavation and dewatering. No curbs, road base, or utilities had to be removed or relocated. This approach saved enormous amounts of additional cost and delays.

Want more information on leak seal and geotech products?

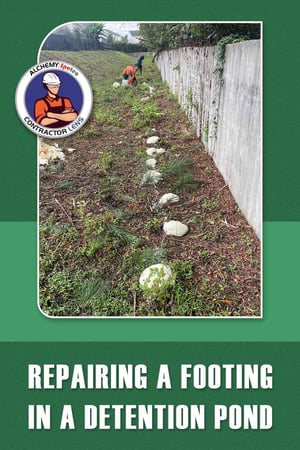

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of SiteMix Pressure Grouting LLC, provides an overview of a repair job on a detention pond wall footer. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of SiteMix Pressure Grouting LLC, provides an overview of a repair job on a detention pond wall footer. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

Causes of Unstable Soil

Causes of Unstable Soil

The Polyurethane Soil Stabilization Process

The Polyurethane Soil Stabilization Process

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to