The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

The residents of a house in Columbia, Missouri noticed the floor in their finished basement was settling. The slab was beginning to sink along the base of a load-bearing wall. It turned out that there was no structural support beneath that area of the floor. They reached out to Absolute Foundation Repair, a local geotechnical contractor. Alchemy-Spetec Geotech Services Technician Jacob Bryant was invited by the contractor to consult on the job as well.

Powerful Polymers

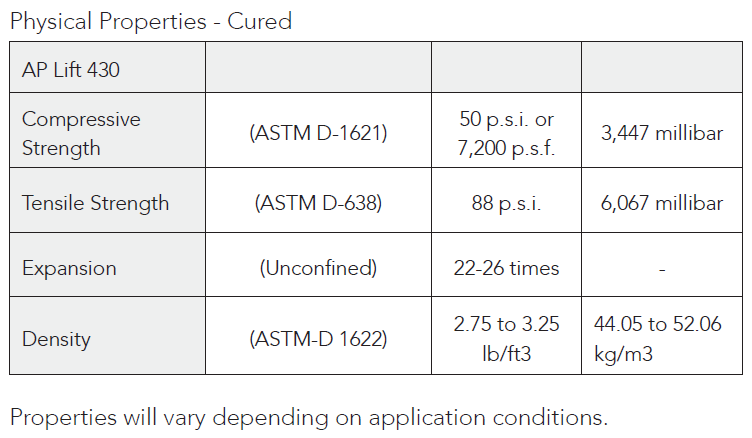

AP Lift 430 is a two-component, high-strength, high-density, hydro-insensitive structural polyurethane foam. This very reliable and consistent material was selected because it is ideal for strengthening and compacting soil. This high-strength closed cell polyurethane bonds with soil and concrete. After installation, the site is often traffic ready in as soon as 15 minutes. AP Lift 430 is also certified to NSF/ANSI/CAN 61 (approved for contact with drinking water).

Painless Procedures

The Alchemy-Spetec technical consultant worked closely with the geotech contractor to develop the injection plan. The crew removed the carpet and then drilled holes every three feet along the length of the affected area. Next, they drove injection tubing through each drill hole, four feet deep into the soil beneath the slab. A technician then injected about 20-40 lbs of AP Lift 430 per tube. The crew monitored for lift during this process. The slab was raised about 1/8 - 1/4 of an inch to ensure that the soil was fully compacted. Next, they injected additional material just beneath the slab (a.k.a. shallow injections) to fill any remaining voids. Finally, they removed the tubes and cleaned up the site.

Rapid Results

After only a few hours, the job was completed, and the site was completely cleaned up. The customer was able to conduct her previously scheduled dance class on that same floor later that day.