This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Morgan Helms of Helms Polyfoam. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article was written by Morgan Helms of Helms Polyfoam. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

Railroads are an integral part of our nation’s infrastructure, and Helms knows how important it is to maintain their structural integrity and operability. Unfortunately, soils beneath railroads and railbeds are subject to settling from water intrusion.

With our structural polyurethane resins that support over 14,000 lbs. per square foot, Helms Polyfoam can stabilize and lift railbeds back to their normal and safe levels. In fact, Helms recently succeeded in solving a railroad repair problem for one of our clients, Gulf Coast Sand, in Picayune, Mississippi.

For this client, a 75-foot section of railway approaching their railcar scale had settled 5-6 inches. This settling was causing inaccurate scale readings due to uneven weight distribution along the scale. When there’s a soil stabilization or settling problem, Helms has the solution!

In order to ensure an even distribution of lift and stabilization, it was determined that varying depths of injections should be made. These injections were spaced on 4-foot centers, at a span of 4 injections wide per track (one injection point on each outer rail and two injections inside of the rail track) for an approximate injection total of 80 injection points.

At each of the 80 total injection points, ½-inch galvanized tubes were probed to a depth of 6 feet and 4 feet, alternating at each injection point. Expanding resins were then injected into the shell mixture at each injection point for stabilization without adding additional lift to the track.

The result? Our injection pattern for Gulf Coast Sand created a soil squeeze where each injection point compressed against the adjacent points to create a solid, rock-hard mass below the surface!

If you need concrete lifting or soil stabilization work done in the Mississippi area, click here to contact Helms Polyfoam today!

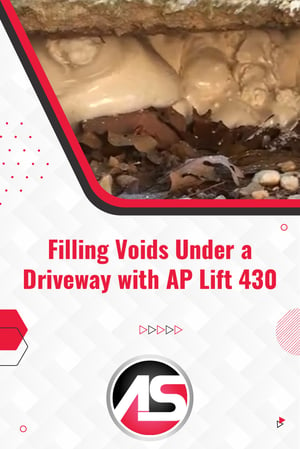

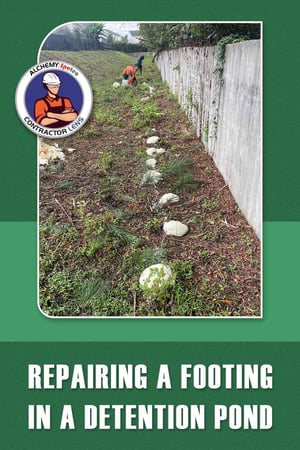

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

A property owner reached out to a geotech contractor for help with a leaking retention pond. The pond feeds into a creek via a concrete spillway. Over the years water has worked its way through the earthen dam and under the spillway, causing large voids and soil loss under the concrete.

The owner of a home in Montana contacted

The owner of a home in Montana contacted

A property owner in Montana contacted geotech contractor

A property owner in Montana contacted geotech contractor

Recently Atlanta-based contractor

Recently Atlanta-based contractor

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use

Soil testing equipment is extremely helpful for planning slab lifting and soil stabilization work. Contractors use

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of