This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, examines the following applications of polyurethane: void fill, slab leveling, and slab lifting. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, examines the following applications of polyurethane: void fill, slab leveling, and slab lifting. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

So, your sidewalk sunk into the muddy mire that used to be your backyard before Fifi dug it up. Or perhaps your cement patio has a new severe slant to it so that you shimmy folded-up pieces of paper underneath your picnic table to make it artificially level. Or maybe you have weak, non-loadbearing soil and your pool is starting to crack due to the strain. The question is: how do you lift and re-level large sections of concrete?

Polyurethane is a panacea, a cure-all, for a long list of soil-related issues. Polyurethane can lift, level, and densify weak soil. Dalinghaus Construction Inc. has been in the foundation repair industry for decades. We are here to educate you on everything to do with polyurethane, whether you choose to employ our services or go with another contractor.

In this article, you will learn the properties of polyurethane foam, how it is utilized for soil densification, slab lift & leveling, and void fill.

What is Polyurethane Foam?

Polyurethane foam is an injectable polyol and isocyanate resin sealant, insulation, grout which expands upon application providing void fill, structural support, and re-leveling properties. Polyurethane foam is waterproof, flame-retardant, noninvasive, and nonpolluting, weighing 3.5 to 5 pounds per cubic foot and reaching 90% compression strength after 15 minutes. Polyurethane can hold up to 7,200 pounds per square foot.

Polyurethane is injected as a liquid before it solidifies into its foam state. Due to the initial liquid form, polyurethane permeates into tight spaces, allowing it to penetrate weak soil and difficult to reach voids. This foam is environmentally inert, posing no danger to the environment or the evolutionarily finely tuned habitat that is your yard.

In other words, your children and your furry pets are safe. In fact, polyurethane itself is so safe it is used in pacemakers and other devices that can be safely implanted into the body.

At Dalinghaus Construction Inc., we utilize AP Lift 430, which is certified by Truesdail Labs to NSF / ANSI 61-5 (meaning it’s approved for contact with drinking water).

Fun Fact with Brian – Polyurethane has quickly usurped mudjacking due to its lighter weight and less invasive application system. Mudjacking slurry weighs up to 140 pounds per cubic foot (which just adds more weight to an already sinking slab). To find out why Polyurethane is a better option than mudjacking, read our article Polyurethane Injection vs Mudjacking (Weight, Application, & Cure Time).

Polyurethane Soil Densification

Polyurethane foam densifies weak, non-loadbearing, expansive soils, such as clays and lay stratum. The polyurethane is pumped deep into the soil (often at varying levels/intervals) and expands as a foam. The polyurethane foam fills gaps and underground pockets that compromise the structural integrity of the soil. This foam solidifies, strengthening the soil by adding light, water retardant support. Polyurethane soil densification can be used to mitigate landslides, for hillside stabilization, and deep injection.

Polyurethane Slab Lift & Leveling

Sidewalks, concrete patios, and backyard basketball courts can sink and become uneven. While it’s tempting to blame the slanted slab for your bad dribbling skills during a pick-up game, it’s always more fun and safer to walk across flat, level surfaces.

A flat working space is especially important in a warehouse environment. Polyurethane foam works beautifully at leveling warehouse slabs to ensure all the warehouse workers are safe. To learn more about warehouse safety, read our other Contractor Lens article on the Alchemy-Spetec blog, Warehouse Floor Repair.

Polyurethane is the perfect candidate to lift and re-level concrete surfaces, due to the expansive properties of the foam. As the foam expands, it pushes upwards, exerting a tremendous amount of force on the slab above, returning it to level.

Polyurethane Void Fill

Polyurethane foam is often utilized as a void fill after a slab lift during an underpinning project. When the affected section of the home is lifted, it leaves a void where the home had settled. Polyurethane is injected, the foam expands, and the void is filled with strong, durable, and supportive material.

*Note – The lifted section of the home always requires void fill (the last pier on each side is referred to as the void fill lifting point). The entire area beneath the slab doesn’t require void fill, only the affected area.

Polyurethane Projects

In this article, you learned about various applications of polyurethane foam in the construction world: soil densification, slab lift & leveling, and void fill.

If you want to learn how invasive polyurethane injection is, read our article 5 Steps to Polyurethane Foam Injection (From Drillholes to Cure).

We have over 100 years of combined experience in the foundation repair game. We are here to educate and assist, whether you ultimately choose us for your polyurethane services or not.

If you live in Southern California or Arizona and would like to book a free foundation inspection, click the link below...

Want more information on slab lifting with polyurethane?

Sometimes lifting concrete slabs with polyurethane is about more than just making something structurally sound and level again. In every town, there are buildings sitting empty because the floors are not in sufficient shape for use by a business. Imagine the service a concrete leveling contractor can provide by bringing slabs back into tolerance and allowing an empty space to become a revenue stream for the building owner. This is what one of our contractors in Omaha, Nebraska did.

Sometimes lifting concrete slabs with polyurethane is about more than just making something structurally sound and level again. In every town, there are buildings sitting empty because the floors are not in sufficient shape for use by a business. Imagine the service a concrete leveling contractor can provide by bringing slabs back into tolerance and allowing an empty space to become a revenue stream for the building owner. This is what one of our contractors in Omaha, Nebraska did.

Many of the contractors I’ve worked with over the years have had to give a presentation at one time or another. In some cases, they need to make a pitch to a potential client (for example at municipality or state agency contract meetings). In other cases, they have the opportunity to market their services by giving presentations at trade shows, “lunch and learn” seminars, webinars, homeowner association meetings, professional association events, etc.

Many of the contractors I’ve worked with over the years have had to give a presentation at one time or another. In some cases, they need to make a pitch to a potential client (for example at municipality or state agency contract meetings). In other cases, they have the opportunity to market their services by giving presentations at trade shows, “lunch and learn” seminars, webinars, homeowner association meetings, professional association events, etc.

Municipalities across North America have widespread problems with Inflow and infiltration (I&I). Inflow is in reference to stormwater that invades sewer systems. Infiltration is in reference to groundwater infiltrating manholes, lift stations, pipes, and other sanitary system components. While there are a few solutions on the market for mitigating inflow, this article is primarily focused on mitigating infiltration with polyurethane grout.

Municipalities across North America have widespread problems with Inflow and infiltration (I&I). Inflow is in reference to stormwater that invades sewer systems. Infiltration is in reference to groundwater infiltrating manholes, lift stations, pipes, and other sanitary system components. While there are a few solutions on the market for mitigating inflow, this article is primarily focused on mitigating infiltration with polyurethane grout.

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of

Andy Powell Promoted to Division Manager - Geotech

Andy Powell Promoted to Division Manager - Geotech

As one of the most impenetrable permeation grouting products on the market,

As one of the most impenetrable permeation grouting products on the market,

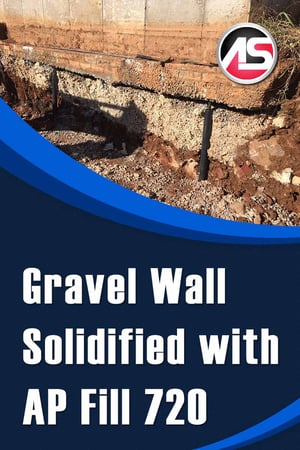

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

One of the most common questions I get about leak seal grout is along the lines of "Can I do this or that? Will it work?". I get this type of question regularly because every job is very unique and there is no one precise grouting procedure that fits everything. Let me introduce you to a term I love to use: exploratory grouting. This is the phase in which you are trying various methods until you find one that works for your particular application. While this just sounds like guesswork, it is very far from that.

One of the most common questions I get about leak seal grout is along the lines of "Can I do this or that? Will it work?". I get this type of question regularly because every job is very unique and there is no one precise grouting procedure that fits everything. Let me introduce you to a term I love to use: exploratory grouting. This is the phase in which you are trying various methods until you find one that works for your particular application. While this just sounds like guesswork, it is very far from that.

New year's message from Alchemy-Spetec Co-Owner and President Stephen C. Barton. (Stephen has been at the forefront of the concrete repair industry for over 30 years. Running leak seal crews in his teens, developing breakthrough polyurethane technology in his twenties, and helping grow the market ever since; Mr. Barton has been a leader in the field for most of his life.)

New year's message from Alchemy-Spetec Co-Owner and President Stephen C. Barton. (Stephen has been at the forefront of the concrete repair industry for over 30 years. Running leak seal crews in his teens, developing breakthrough polyurethane technology in his twenties, and helping grow the market ever since; Mr. Barton has been a leader in the field for most of his life.)