Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Hydrophobic

- Cured States: Rigid, Semi-Rigid, Flexible Foam

- Reaction: Requires Water

- Requires Accelerator: Yes

- Elongation: None to 100%

- Wet/Dry Cycling: Unaffected

- Adhesive Bond: Good

- Pumped and Handles as: Single Component

Hydrophilic

- Cured States: Flexible Foam or Gel

- Reaction: Requires Water

- Requires Accelerator: No

- Elongation: None to 300%

- Wet/Dry Cycling: Can Dry Out

- Adhesive Bond: Superior

- Pumped and Handles as: Single Component

Somehow, the industry has erroneously assumed hydrophobic means: "fears water and pushes it away". While at the same time assuming hydrophilic means: "loves water and draws it in". There are some truths in these statements but they are only the core and are wrapped in misconceptions.

Misconception One: Water Loving and Water Fearing

Both grouts require water to activate and yes, the hydrophilic grout can incorporate more of the water into its cell structure, but both grouts will push water away when they have reacted with enough water to polymerize.

Misconception Two: Hydrophilic Grouts Dry Out and Shrink Without Water

A more accurate statement would be that cured hydrophilic urethane grouts can dry out and shrink in an arid environment. Concrete normally has a relative humidity of around 60% which will keep a hydrophilic foam hydrated. Soils can vary in their relative humidity but most often have enough moisture not only to keep a hydrophilic grout hydrated but also enough to polymerize a hydrophobic grout without the need for added water.

Misconception Three: Hydrophilic Grouts Have Better Adhesion

It is 100% true hydrophilic grouts have better adhesion in ASTM lab testing, and I did just list them as having superior adhesion. But, in my twenty-plus years in construction, I have never seen a grout job performed under laboratory conditions. Adhesion requires a clean surface for bonding. During crack injection, surface prep is a water flush in a crack we cannot see. So clearly it would be silly to believe we have a pristine surface inside the crack to adhere to. So yes, in a lab, hydrophilic grouts adhere to concrete better than hydrophobic grouts. In situ, both have a weak adhesive bond and both rely on their compressive and mechanical bonds much more than on an adhesive bond.

So, it's important to understand there is much more to grout selection than just hydrophilic and hydrophobic. I would estimate around 60% of chemical grouters only chemical grout a few times year. This can make product and methodology selection very difficult. That is why I am here with the Alchemy-Spetec team to help navigate you through these critical nuances. Call us at 404-618-0438 for technical assistance!

Want more information about leak seal products?

A large Mid-Western aluminum manufacturer was losing water from all of its quenching tanks. Losing 3 million gallons in half a year can be expensive, not to mention the massive effect that volume of water can have on soil and the structures it supports. So, they reached out to one of their trusted maintenance contractors, who in turn came to Alchemy-Spetec for guidance on how to efficiently mitigate the leaks with minimal downtime.

A large Mid-Western aluminum manufacturer was losing water from all of its quenching tanks. Losing 3 million gallons in half a year can be expensive, not to mention the massive effect that volume of water can have on soil and the structures it supports. So, they reached out to one of their trusted maintenance contractors, who in turn came to Alchemy-Spetec for guidance on how to efficiently mitigate the leaks with minimal downtime.

Enjoy the Advantages and Avoid the Pitfalls

Enjoy the Advantages and Avoid the Pitfalls

We've created a video for a question we get asked a lot: "How do I make single-component samples?" A lot of people want samples, sales teams love samples, homeowners love them because it’s actually something they can put in their hands on. They can really help close a deal.

We've created a video for a question we get asked a lot: "How do I make single-component samples?" A lot of people want samples, sales teams love samples, homeowners love them because it’s actually something they can put in their hands on. They can really help close a deal.

Like with most issues, there is no one final answer, but let’s weigh the pros and cons. An easy one is cost: two-component urethanes are significantly more cost-effective than a single component IF you already have a rig to properly handle them. Keep in mind, not many leak seal contractors typically have a rig.

Like with most issues, there is no one final answer, but let’s weigh the pros and cons. An easy one is cost: two-component urethanes are significantly more cost-effective than a single component IF you already have a rig to properly handle them. Keep in mind, not many leak seal contractors typically have a rig.

Andrew has over 10 years of experience in Manufacturing Operations and Quality Assurance. With a Six Sigma Black Belt certification, he has a successful track record of evaluating complex manufacturing operations, identifying inefficiencies, and implementing process improvements.

Andrew has over 10 years of experience in Manufacturing Operations and Quality Assurance. With a Six Sigma Black Belt certification, he has a successful track record of evaluating complex manufacturing operations, identifying inefficiencies, and implementing process improvements.

Alchemy-Spetec is pleased to welcome Jacob Bryant to our technical support team. Jacob joins the company as Geotech Services Technician. He'll be working with Cult Hullander (Director of Technical Services - Geotech).

Alchemy-Spetec is pleased to welcome Jacob Bryant to our technical support team. Jacob joins the company as Geotech Services Technician. He'll be working with Cult Hullander (Director of Technical Services - Geotech).

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

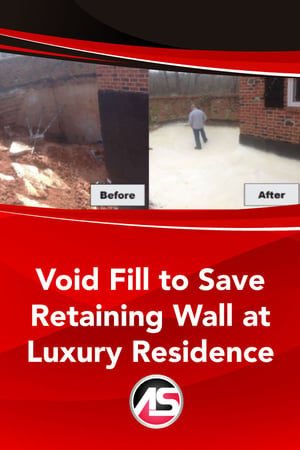

A retaining wall at a Georgia-based luxury residence was failing due to the pressure of the surrounding soil. A general contractor excavated the site around the wall and planned to install lightweight foam blocks as a replacement for the heavy soil that was removed. After doing a little more research, the contractor discovered that, due to the cost of shipping the blocks, liquid polyurethane foam installation by a local specialized contractor was a lot less expensive. Liquid polyurethane foam takes the shape of the void before curing to form a high-strength solid mass.

A retaining wall at a Georgia-based luxury residence was failing due to the pressure of the surrounding soil. A general contractor excavated the site around the wall and planned to install lightweight foam blocks as a replacement for the heavy soil that was removed. After doing a little more research, the contractor discovered that, due to the cost of shipping the blocks, liquid polyurethane foam installation by a local specialized contractor was a lot less expensive. Liquid polyurethane foam takes the shape of the void before curing to form a high-strength solid mass.