This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, provides an overview of polyurethane concrete repair material. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of Dalinghaus Construction, provides an overview of polyurethane concrete repair material. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec.com today!

Perhaps a foundation repair contractor has suggested polyurethane foam for deep injection, void fill, or slab lifting/leveling, but you’re not so sure about pumping “plastic” into the earth or underneath your home. You’re probably wondering: is polyurethane environmentally friendly? Is it effective?

If you’re concerned about the use of polyurethane for foundation repair and soil densification or just want to know more general information about PU, this article is for you.

Dalinghaus Construction Inc. has been in the foundation repair game since 2015. We have over 100 years of combined foundation repair experience and have serviced thousands of foundations in Southern California and Arizona via polyurethane-related repairs. We know everything there is to know about polyurethane and we’re here to share.

In this article, you will learn the definition of polyurethane, its history, many general uses, and how polyurethane foam is utilized in foundation repair.

What is Polyurethane?

Before you pump gallons of polyurethane foam underneath your home or into the soil around your property, you probably want to know what exactly it is.

Polyurethane Definition

Polyurethane is a synthetic resin compound comprised of carbamate/urethane groups linked to polymer units, often abbreviated as PU or PUR. In other words, polyurethane is a combination of chemicals/compounds that react to create a plastic-like substance. As a solid, polyurethane has an open-cellular structure – which is a foam.

Polyurethane foam, utilized for many purposes including insulation, sound-proofing, and foundation repair, is created by the chemical reaction of Diisocyanates and polyols (both of which are derived from organic crude oil). Because polyurethane is comprised of organic material, it is environmentally friendly and does not contribute to an increased eco-footprint.

According to the Polyurethane definition, it is not a plastic. Technically, the elongated flexible polymer molecules that make up thermoset polyurethanes categorize this material as an elastomer (a natural or synthetic polymer having elastic properties, e.g., rubber).

Polyurethane foam is a safe, eco-friendly option to densify weak, non-load-bearing soil, void fill beneath your foundation following a lift/stabilization and relevel slabs.

History of Polyurethane

Polyurethane was invented in 1937 by the renowned German Professor Dr. Otto Bayer. Dr. Otto Bayer was an industrial chemist and worked for IG Farben – spearheading the research team that discovered polyaddition (the key to synthesis for polyurethanes by combining polyol and polyisocyanate).

Polyurethane first enjoyed widespread use in World War II as a rubber substitute. Polyurethane was utilized as airplane finishes, various coatings, and to create flame-retardant clothing. By the 1950s, Polyurethane was utilized for many different applications: couch cushion foam, rigid foams, elastomers, and adhesives.

Today, polyurethane is utilized for a wide variety of applications: mattresses, shoe soles, car seats, insulation, and even pacemakers. Polyurethane is a “behind the scenes” product, often hidden behind a layer of fabric, plastic, or other encasing material.

Due to its prevalence, in everything from car seats to pacemakers, it’s truly difficult to grasp the full scope and impact of polyurethane in everyday life – however, its importance in the foundation repair game is easy to explain.

Polyurethane and Foundation Repair

The foundation repair industry uses polyurethane foam primarily for soil densification, void fill, and lifting/leveling slabs back into place. Polyurethane foam is an injectable polyol and isocyanate resin sealant, insulation, grout which expands upon application providing void fill, structural support, and re-leveling properties.

The polyurethane foam is installed via an application gun: the polyols (a type of alcohol, containing multiple hydroxyl groups) and diisocyanate/polymeric isocyanate are pumped separately, but simultaneously. The chemicals combine and react after exiting the application gun.

The foam then expands, filling the void, densifying the soil, or lifting the slab back into place. In short, polyurethane has incredible expansive properties, allowing it to fill voids evenly and with ease – providing strength and support to the affected structure.

Here at Dalinghaus Construction Inc., we use Alchemy-Spetec's AP Lift 430 (which has been certified by Truesdail Labs to NSF/ANSI 61-5 – meaning it’s approved for contact with drinking water).

AP Lift 430 is:

- Waterproof (Hydrophobic)

- Noninvasive (Install Process is More Efficient and Replacing Concrete)

- Nonpolluting (NSF Approved for Contact with Potable Water)

In addition, AP Lift 430 weighs approximately 3 pounds per cubic foot and reaches 90% compression strength in only 15 minutes. And, finally, polyurethane can hold 7,200 pounds per square foot. In short, polyurethane is a fantastic solution for foundation repair and hillside stabilization needs.

Polyurethane Foam is Safe, Effective, and Environmentally Friendly

In this article, you learned the definition of polyurethane, how it was invited by Dr. Otto Bayer, the wide spectrum of uses, and how polyurethane foam is utilized in foundation repair and construction. You also learned that polyurethane is a safe and effective product. Dalinghaus Construction has helped hundreds of homeowners and offers an array of services, including carbon fiber crack repair, steel pier underpinning, and more.

Click here if you live in Southern California or Arizona and would like to book a free foundation inspection.

Want more information on polyurethane repair products?

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

Alchemy-Spetec products are proudly made in the U.S.A. Manufacturing at the Tucker, GA, and Reno, NV facilities (rather than outsourcing abroad) provides three distinct advantages to you and to the country we all call home: consistent quality, reliable supply, and more American jobs.

Alchemy-Spetec products are proudly made in the U.S.A. Manufacturing at the Tucker, GA, and Reno, NV facilities (rather than outsourcing abroad) provides three distinct advantages to you and to the country we all call home: consistent quality, reliable supply, and more American jobs.

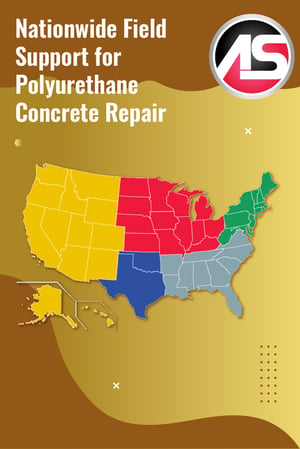

Alchemy-Spetec offers unparalleled field support through our nationwide team of Regional Managers and Technical Service Directors. No matter what part of the industry you are in, we know you could very well be busy and understaffed with unprecedented crew member turnover. There’s never been a time where experience in the field has been more needed. Spreading your leadership staff all over the field is expensive and draining. And you never quite know what you’ll get with unproven local talent. Alchemy-Spetec's top-shelf support squad will help your crews get the job done safely and properly.

Alchemy-Spetec offers unparalleled field support through our nationwide team of Regional Managers and Technical Service Directors. No matter what part of the industry you are in, we know you could very well be busy and understaffed with unprecedented crew member turnover. There’s never been a time where experience in the field has been more needed. Spreading your leadership staff all over the field is expensive and draining. And you never quite know what you’ll get with unproven local talent. Alchemy-Spetec's top-shelf support squad will help your crews get the job done safely and properly.

Polyurethane chemical grout injection can be a bit of a Pandora’s box at times. So, what can be done to help combat some of these uncertainties? Well, how about the easiest and most cost-effective solution first. Oakum! Not only is it amazing what you can accomplish with it, but it is vital to have on every job. YES, I SAID EVERY JOB.

Polyurethane chemical grout injection can be a bit of a Pandora’s box at times. So, what can be done to help combat some of these uncertainties? Well, how about the easiest and most cost-effective solution first. Oakum! Not only is it amazing what you can accomplish with it, but it is vital to have on every job. YES, I SAID EVERY JOB.

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

On March 29th - 31st, Contractors from around the world traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Brian Dalinghaus of

Do not get caught off guard. It’s crucial to determine if the project you are bidding requires products that meet NSF/ANSI/CAN 61 standards for contact with drinking water. But what exactly are NSF/ANSI/CAN 61 standards? Our goal here is to provide a concise and comprehensive overview of why NSF approval is important for polyurethane concrete repair chemical grouts.

Do not get caught off guard. It’s crucial to determine if the project you are bidding requires products that meet NSF/ANSI/CAN 61 standards for contact with drinking water. But what exactly are NSF/ANSI/CAN 61 standards? Our goal here is to provide a concise and comprehensive overview of why NSF approval is important for polyurethane concrete repair chemical grouts.

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20-foot trailer rig. The setup is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck! With this equipment, you can handle most every flatwork type of concrete lifting, be it residential or commercial. Of course, void filling beneath slabs and structures is also within the capability of the machine.

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20-foot trailer rig. The setup is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck! With this equipment, you can handle most every flatwork type of concrete lifting, be it residential or commercial. Of course, void filling beneath slabs and structures is also within the capability of the machine.

Alchemy-Spetec's Spring 2022 training event is officially SOLD OUT! If you're still interested in training, we'll be conducting another event in the Fall of 2022. Click the button below and fill out the form. We'll keep you updated on the next event and all other training opportunities!

Alchemy-Spetec's Spring 2022 training event is officially SOLD OUT! If you're still interested in training, we'll be conducting another event in the Fall of 2022. Click the button below and fill out the form. We'll keep you updated on the next event and all other training opportunities!

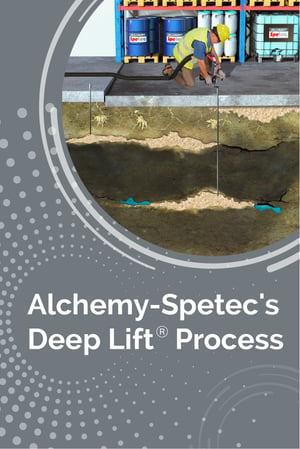

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Common methods of addressing deep soil issues require heavy equipment, extended downtime, and collateral property damage. These situations create problems for property owners as well as opportunities for specialty contractors that know how to fix them.

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Common methods of addressing deep soil issues require heavy equipment, extended downtime, and collateral property damage. These situations create problems for property owners as well as opportunities for specialty contractors that know how to fix them.