So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

So, you have another clog in your boot? Well, your grain elevator boot that is. This means shutting down to clean your grain elevator. Which means loss of production, loss of grain, and delays. Drains and sump pumps clog and can be unreliable.

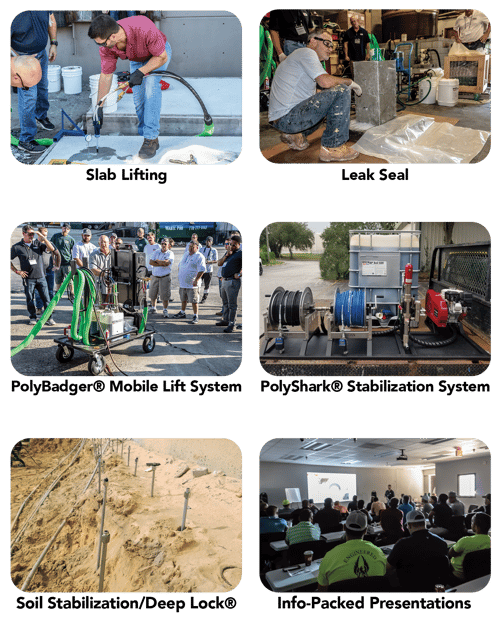

A grain cooperative in Washington state contacted Kodiak Concrete Lifting. Alchemy-Spetec's Leak Seal Division Director of Technical Services, Charlie "The Grout Geek" Lerman, met Kodiak on-site and inspected the leaking boots in question. One was poured concrete and the other was poured concrete with a metal interior liner. Both had multiple areas of water intrusion and sumps that were not able to handle the leakage. Charlie worked with Kodiak on developing a grouting plan and an estimate for the co-op.

Powerful Polymer

Spetec PUR HighFoamer was the ideal grout for forming a positive side waterproof barrier known as a curtain wall without having to excavate and with very little downtime.

Spetec PUR HighFoamer is a highly expansive grout (40x-50x) and it is also NSF 61-approved for potable water use.

Painless Procedure

Pumping polyurethane grouts is done with a modified airless paint sprayer. Since this pump is lightweight, it is easy to mobilize in remote or difficult-to-access locations. Normally, the technicians would set up a 2’ on-center grid pattern for curtain wall grouting. With the elevator equipment layout, they had to adjust the spacing. By pumping hole to hole they ensured water-tight grout coverage even with the irregular port spacing.

Rapid Result

A few weeks later, Charlie Lerman and Kodiak met back on-site for the installation. While working in a grain elevator pit and working with urethanes can be a bit messy, the injections went well and the water intrusions were stopped in both pits on time and under budget.

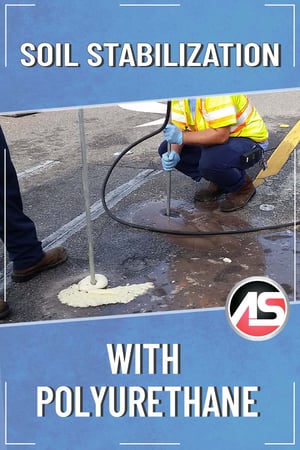

Unstable soil can be a real nightmare. Existing structures, new construction projects, and excavation projects alike require strong supporting soil. Rain, freeze-thaw cycles, erosion, poor compaction, and excessive water saturation all pose a threat. The planet consists of 70% water and 30% land. Unstable soil is everywhere.

Unstable soil can be a real nightmare. Existing structures, new construction projects, and excavation projects alike require strong supporting soil. Rain, freeze-thaw cycles, erosion, poor compaction, and excessive water saturation all pose a threat. The planet consists of 70% water and 30% land. Unstable soil is everywhere.

Repair Cracks and Joints in Concrete

Repair Cracks and Joints in Concrete

Frank Dudley has worked in the polyurethane foam industry for over 15 years. He is well-versed in commercial and industrial spray foam and slab jacking as a project manager, including significant experience with new company start-ups. His project management expertise ranges from small jobs to large operations requiring hundreds of technicians. As a Sales Manager in Western Canada for a major US polyurethane manufacturing company, Frank spent five years providing critical assistance and support to customers in the region. Throughout his career, Frank has worked in various locations around the globe in a variety of industries including fireproofing, coatings, grouting & CPG materials.

Frank Dudley has worked in the polyurethane foam industry for over 15 years. He is well-versed in commercial and industrial spray foam and slab jacking as a project manager, including significant experience with new company start-ups. His project management expertise ranges from small jobs to large operations requiring hundreds of technicians. As a Sales Manager in Western Canada for a major US polyurethane manufacturing company, Frank spent five years providing critical assistance and support to customers in the region. Throughout his career, Frank has worked in various locations around the globe in a variety of industries including fireproofing, coatings, grouting & CPG materials.

A major culvert restoration project was recently completed by

A major culvert restoration project was recently completed by

Tony Gomes brings over 20 years of scaling company growth while ensuring organizational excellence. Tony has a deep passion for people, building teams, and leading them to success. With over 12 years of construction experience under his belt, he has become adept at most facets of the construction space. The client is put at the center of everything he does and although he loves to win, helping the team achieve its goals gives him his greatest joy and satisfaction.

Tony Gomes brings over 20 years of scaling company growth while ensuring organizational excellence. Tony has a deep passion for people, building teams, and leading them to success. With over 12 years of construction experience under his belt, he has become adept at most facets of the construction space. The client is put at the center of everything he does and although he loves to win, helping the team achieve its goals gives him his greatest joy and satisfaction.