Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

Back in the 1990s, the Seaholm Power Plan in the City of Austin, TX closed after four decades of operation. Recently, the entire area has been converted into an indoor-outdoor park and public space called the Seaholm Waterfront. All that's left standing of the original power plant is an intake building that the city decided to repurpose for public use as part of the project. Thirty feet below grade, are chambers that were originally designed to hold water from the river and pump it into the power plant to cool the machinery. The intake building renovation project hit a snag when they discovered that several thousand gallons of water were pouring into the chambers on a daily basis.

"Sealing of the intake gates was necessary in order to eliminate water from being continuously present within the building. Nine of the 10 wells have been successfully sealed off. While pumping the water out of the building, leaks were discovered in one of the wells which will require additional work by the underwater construction crew. Preventing the free-flowing entry of lake water into the building is central to the scope of this project improving the occupancy conditions by lowering humidity levels, eliminating odors and pests, and preserving the integrity of the building materials."

— Austin City Council, April 21, 2021

Initially, concrete was poured into the chambers to stop the leak. This proved to be ineffective and further complicated the job. Specialty contractors Canalco were brought in to seal the leaks via polyurethane curtain grouting, in which the technicians drill holes through concrete and inject water-activated grout on the other side, stopping the leak at its source. Technical assistance was provided by Chamberlin Waterproofing.

Powerful Polymer

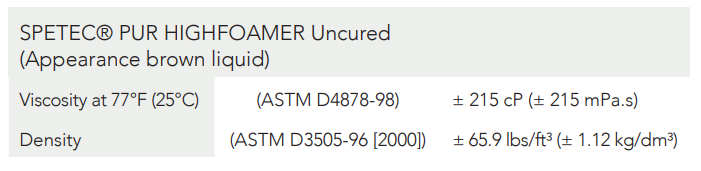

The engineering firm Wiss, Janney, Elstner Associates, Inc., specified Spetec PUR HighFoamer as the best grout to handle these high-pressure leaks. Technicians can easily adjust the set time for this material. They can speed it up for gushing leaks and slow it down to maximize coverage and penetration into the substrate for curtain grouting.

Painless Procedure

A small crew sent a confined entry certified technician deep into the well to drill 1.25" injection holes 4-7' feet through the concrete. Next, he injected Spetec PUR HighFoamer through five holes to create a grout curtain on the outside of the structure to seal off the leaks.

Rapid Result

The job was completed in just one week. The city continues to monitor the situation and the results have been spectacular given the difficulty of the job and the complications.