In January of 2020, Alchemy-Spetec launched The Injection Connection podcast, hosted by Jim Spiegel. Jim is the Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute. As of August 2020, there are eight episodes packed with valuable industry information.

In January of 2020, Alchemy-Spetec launched The Injection Connection podcast, hosted by Jim Spiegel. Jim is the Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute. As of August 2020, there are eight episodes packed with valuable industry information.

If you've missed any of these podcast posts, we invite you to review the guide below...

Episode One - Introduction

Episode 1 is a brief intro about the host, Jim Spiegel, and the intended content of the show. The Injection Connection is produced for contractors, distributors, and design professionals in the infrastructure repair segment, or broader construction industry. The podcast aims to provide unique insights through the lens of the chemical grouting industry.

Episode Two - The QP Factor

This episode is an overview of the patented QP Factor system used to quantify chemical grout leak seal success. The presentation was originally given at the ICRI National Convention by Jim Spiegel, and is being reproduced remotely for an engineering firm in the San Francisco Bay Area. This is the industry's first patented method for leak seal quantification.

Episode Three - Interview with Kevin Earles

Guest Kevin Earles is a long-time friend of Jim Spiegel, and the National Sales Director for EPMS Supplies based in Nottingham, UK. Topics covered include how they met one another, the future of online distribution, Brexit, and more. Kevin has been in the speciality construction distribution industry for almost 25 years.

Episode Four - Interview with Adam Tracy

Guest Adam Tracy, of A-1 Foundation Crack Repair, offers a unique perspective into the residential leak seal industry through his Civil Engineering education. Adam and Jim discuss differences in residential vs.commercial projects, as well as finding new talent, learning from contractors, and more.

Episode Five - Helms Polyfoam

The Injection Connection welcomes two guests from Helms Polyfoam: JR Crowell, VP & COO, and Morgan Helms, President & CEO. In this episode, Jim Spiegel discusses the history of the Helms business, the future of customer support, and the importance of relationships.

Episode Six - Jack Whitworth

Jim and guest Jack Whitworth, 26-year chemical grouting sales professional, discuss the importance of education, mutual benefits of competitors working together, and driving our families crazy during the Covid-19 lockdown time.

Episode Seven - Ann Thaxton

On Episode 7 of The Injection Connection, Jim sits down with Ann Thaxton, from Concrete Titans, a marketing and advertising agency offering services to the concrete lifting, and residential foundation repair markets. Ann offers great insights into the most current lead capture strategies, trends in the industry, and how marketing dollars are actually worth more in the current Covid-19 crisis.

Episode Eight - Matt & Travis of Lift It Rite

On Episode 8 of The Injection Connection, Jim sits down with Matt Chittick and Travis Germick, co-owners of Lift It Rite, LLC., a residential slab-lifting business servicing the Greater Atlanta and surrounding markets. Matt and Travis offer valuable insights on how to start a lifting business, production considerations, and the under-appreciated value of showing up with a smile (and perhaps a hamburglar costume!).

Check out the podcast on TheInjectionConnection.com and the following platforms:

Want info on Alchemy-Spetec products & applications?

On this episode of The Injection Connection, Jim Spiegel welcomes colleague Charlie Lerman "The Grout Geek". Charlie and Jim do their best to take off their Alchemy-Spetec hats and to discuss the Leak Seal® chemical grouting industry through the eyes of a Field Services Manager. With over 16 years of field experience representing some of the most well-known brands in the industry, Charlie is a wealth of knowledge for any listener. (Jim Spiegel is Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute.)

On this episode of The Injection Connection, Jim Spiegel welcomes colleague Charlie Lerman "The Grout Geek". Charlie and Jim do their best to take off their Alchemy-Spetec hats and to discuss the Leak Seal® chemical grouting industry through the eyes of a Field Services Manager. With over 16 years of field experience representing some of the most well-known brands in the industry, Charlie is a wealth of knowledge for any listener. (Jim Spiegel is Vice President of Alchemy-Spetec and a Board Member at the International Concrete Repair Institute.)

A self-described philanthropic entrepreneur, David Park is committed to creating value-driven opportunities that are both scalable and profitable. He has spent the last 15 years developing communities, organizations, and businesses by leading them to discover their full potential, develop a wider vision, and determine the best course of action to achieve their goals.

A self-described philanthropic entrepreneur, David Park is committed to creating value-driven opportunities that are both scalable and profitable. He has spent the last 15 years developing communities, organizations, and businesses by leading them to discover their full potential, develop a wider vision, and determine the best course of action to achieve their goals.

With over 10 years of experience, Joel has a broad understanding of general practices in the construction and services industries. He has spent the last 6 years focused on ground improvement by use of chemical grouting with structural polymers, and possesses both technical and marketing expertise. His background includes contract negotiations, injection plan design, project management, market education, and hands on application of a variety of polymer solutions. Joel utilizes his industry knowledge to assist contractors with marketing strategies, material needs, and product application. Located in the Pacific Northwest, he enjoys his spare time in the great outdoors.

With over 10 years of experience, Joel has a broad understanding of general practices in the construction and services industries. He has spent the last 6 years focused on ground improvement by use of chemical grouting with structural polymers, and possesses both technical and marketing expertise. His background includes contract negotiations, injection plan design, project management, market education, and hands on application of a variety of polymer solutions. Joel utilizes his industry knowledge to assist contractors with marketing strategies, material needs, and product application. Located in the Pacific Northwest, he enjoys his spare time in the great outdoors.

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides

With 1,350 miles of coastline, Florida is home to countless seawalls. If you're a property owner or manager in the Sunshine State, you have landed in the right place. Alchemy-Spetec provides

In January of 2020, Alchemy-Spetec launched

In January of 2020, Alchemy-Spetec launched

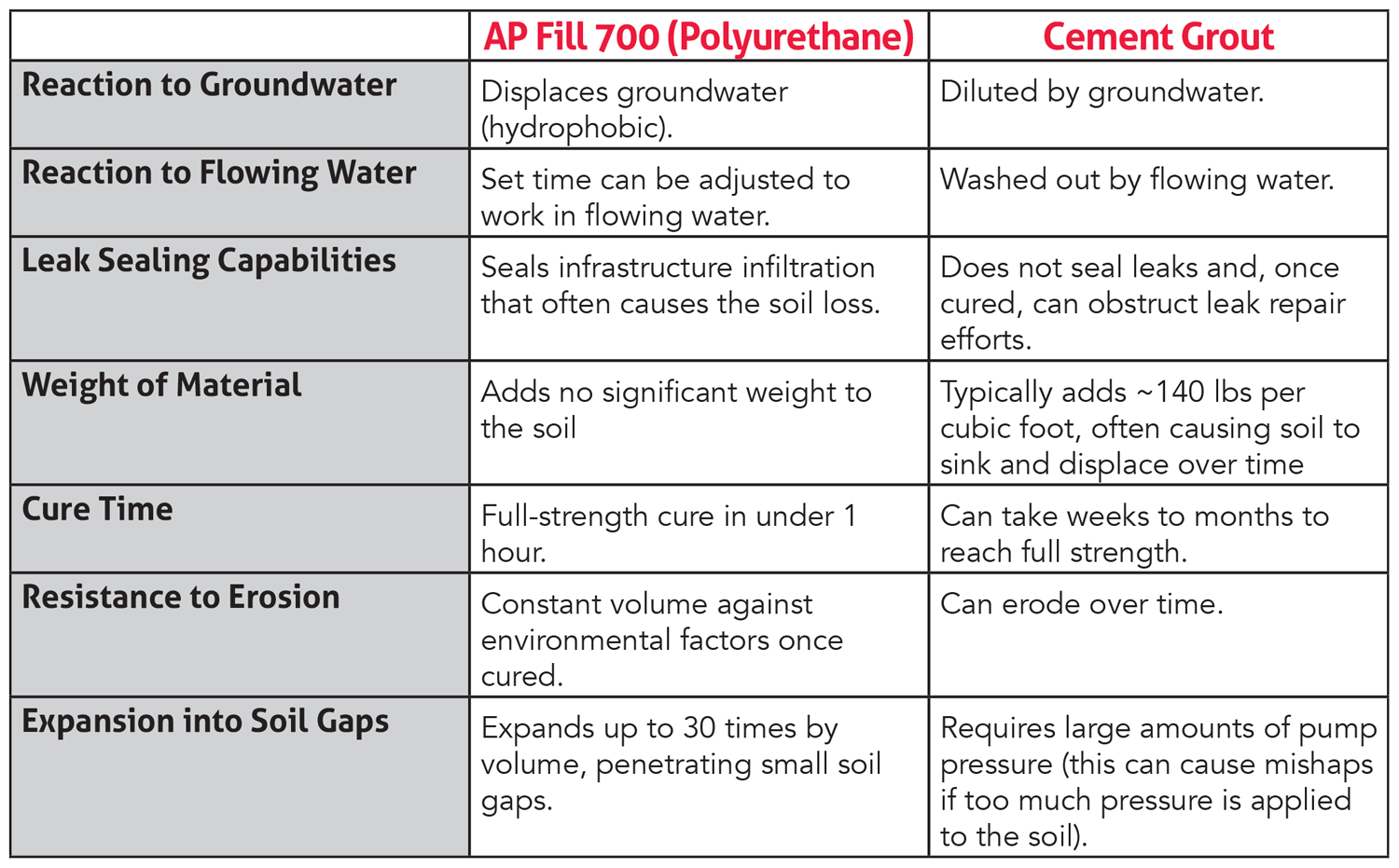

One request we often receive is to explain the difference between

One request we often receive is to explain the difference between