I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.

I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.

It’s easy when discussing a trailer or box truck rig setup to focus on what type of plural component machine you are running. We all want to know whether you have a PH-2 or an E30 for example, or maybe an air powered Boss proportioner. What is often overlooked and neglected is the compressed air system in the rig. For a slab lifting contractor, it’s likely your air system is working harder than any other component on your rig. If you have had the joy of standing next to the compressor while it is running, you can’t deny that.

I want to highlight the main components of the compressed air system; describing their purpose and offering a few tips for keeping them running like they’re supposed to.

These components include:

- Air Compressor

- Coalescing Filter and Moisture Separator

- Refrigerated Air Dryer

Air Compressor

The majority of slab lifting rigs we see have reciprocating air compressors, also known as piston air compressors. These are identified by having a tank, and they are in a horizontal or upright configuration. They can be either gasoline or electric powered. There are also rotary screw compressors out there which don’t have a tank but still need to be maintained. If you have a compressor with a tank, that tank needs to be drained of the moisture it collects. Some have automatic drains that pop open after the unit shuts down; others must be drained manually.

Last week we worked with a contractor who had an air powered proportioner. His machine could build up pressure, but once he started injecting poly the flow would slow down to just a trickle. He would then shut off the gun and the proportioner would pressure up again. Turns out the air compressor tank was almost completely full of water so he would exhaust the remaining air supply right away when shooting the foam. A good policy is to drain the tank every day at the end of the shift. If it doesn’t drain automatically then there are typically valves that are easy to access. I actually like to start my compressor up the next shift with the tank valve open because it will always blow some more water out when it fires up. Then I shut the valves and things pressure up per usual.

In addition to draining the tank, you need to check and change the compressor oil per the manufacturer’s guidelines. This is for all compressors. If you don’t have a manual on board the rig to tell you when to change the oil or what oil to put in, this info can easily be found on the internet or hopefully from your rig provider.

Filters and Moisture Separators

You can usually find the moisture filter and separator mounted on the wall, often combined with the regulator and air pressure gauge. These filters have a housing below them that collects moisture that is coming from the air compressor. This is the first line of defense (after the air compressor) from keeping moisture out of your transfer pumps, so make sure to open the little valves at the bottom and drain these filter/separators daily. I do it at the end of the day and once again at the beginning of the shift when I am checking my air pressure upon startup.

Refrigerated Air Dryers

The refrigerated air dryer is the last line of defense before the compressed air is sent over to the transfer pumps. I have seen these mounted in various places in a rig from on the floor to up on the wall. First, do not pile tools and other rig items on top of and around the air dryer. These units work nonstop, and they need airflow to do their job without overheating. Take care not to block them in. Second, I believe most of these air dryers also have filters and coils that need to be cleaned occasionally. Check the manufacturers guidelines for your model and keep those items clean so that your unit can run more efficiently and for a longer life.

Conclusion

Your compressed air system is vital to your plural component machine running on ratio and making good polyurethane foam. Components that remove moisture from the air are critical for keeping your transfer pumps running like they are supposed to without breaking down or losing pressure.

Always keep these critical points in mind:

- Drain the tank

- Change the oil

- Drain the filter/separator units

- Don’t block in your refrigerated air dryer, and keep the unit clean

These essential maintenance tasks don’t take but a few minutes, and they can save you hours of frustration and head scratching.

Want more information on Geotech material and equipment?

This article is an excerpt from Episode 9 of Alchemy-Spetec's podcast The Injection Connection, featuring Charlie Lerman "The Grout Geek". Charlie is Director of Technical Services - Leak Seal® Division at Alchemy-Spetec. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this excerpt is posted at the bottom of the article.)

This article is an excerpt from Episode 9 of Alchemy-Spetec's podcast The Injection Connection, featuring Charlie Lerman "The Grout Geek". Charlie is Director of Technical Services - Leak Seal® Division at Alchemy-Spetec. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this excerpt is posted at the bottom of the article.)

I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.

I don’t know what it is about this time of year but for some reason at the beginning of fall we receive the most tech support phone calls from slab lifting contractors. Some of it is related to the changing weather, but this past week several things happened that made me want to address a specific topic – the compressed air system of the polyurethane foam rig.

The choice of a polyurethane material provider for your geotechnical contracting business is a critical decision with far-reaching consequences. In addition to top quality concrete and soil repair material, a premier provider will offer reliable high-performance equipment, rock-solid tech support, extensive training resources and even marketing assistance.

The choice of a polyurethane material provider for your geotechnical contracting business is a critical decision with far-reaching consequences. In addition to top quality concrete and soil repair material, a premier provider will offer reliable high-performance equipment, rock-solid tech support, extensive training resources and even marketing assistance.

The INJECTR Series single cartridge houses grout and accelerator in two separate interior compartments. The grout and accelerator are thoroughly blended when injected through the static mixer. This cartridge is compatible with standard caulk guns.

The INJECTR Series single cartridge houses grout and accelerator in two separate interior compartments. The grout and accelerator are thoroughly blended when injected through the static mixer. This cartridge is compatible with standard caulk guns.

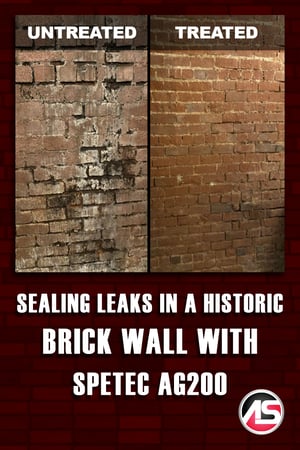

As the Director of Technical Services for the Leak Seal division at Alchemy-Spetec, I often find myself assisting customers with some interesting jobs. Such was the case when I was called in to consult with a contractor who was sealing a leak in a historic district below-grade, multi-course brick wall. As is often the case with below grade, historic spaces, water infiltration was unsightly, gave off a musty odor, and was damaging to finishes. This was a very old brick wall, approximately 8 x 15 feet in size and at least three courses thick. The owner wanted to find a way to waterproof this vintage brick structure while at the same time preserving its unique appearance. In addition to the water flow issue, the leaks were causing mold/mildew on the walls.

As the Director of Technical Services for the Leak Seal division at Alchemy-Spetec, I often find myself assisting customers with some interesting jobs. Such was the case when I was called in to consult with a contractor who was sealing a leak in a historic district below-grade, multi-course brick wall. As is often the case with below grade, historic spaces, water infiltration was unsightly, gave off a musty odor, and was damaging to finishes. This was a very old brick wall, approximately 8 x 15 feet in size and at least three courses thick. The owner wanted to find a way to waterproof this vintage brick structure while at the same time preserving its unique appearance. In addition to the water flow issue, the leaks were causing mold/mildew on the walls.

On this episode of

On this episode of

A self-described philanthropic entrepreneur, David Park is committed to creating value-driven opportunities that are both scalable and profitable. He has spent the last 15 years developing communities, organizations, and businesses by leading them to discover their full potential, develop a wider vision, and determine the best course of action to achieve their goals.

A self-described philanthropic entrepreneur, David Park is committed to creating value-driven opportunities that are both scalable and profitable. He has spent the last 15 years developing communities, organizations, and businesses by leading them to discover their full potential, develop a wider vision, and determine the best course of action to achieve their goals.

With over 10 years of experience, Joel has a broad understanding of general practices in the construction and services industries. He has spent the last 6 years focused on ground improvement by use of chemical grouting with structural polymers, and possesses both technical and marketing expertise. His background includes contract negotiations, injection plan design, project management, market education, and hands on application of a variety of polymer solutions. Joel utilizes his industry knowledge to assist contractors with marketing strategies, material needs, and product application. Located in the Pacific Northwest, he enjoys his spare time in the great outdoors.

With over 10 years of experience, Joel has a broad understanding of general practices in the construction and services industries. He has spent the last 6 years focused on ground improvement by use of chemical grouting with structural polymers, and possesses both technical and marketing expertise. His background includes contract negotiations, injection plan design, project management, market education, and hands on application of a variety of polymer solutions. Joel utilizes his industry knowledge to assist contractors with marketing strategies, material needs, and product application. Located in the Pacific Northwest, he enjoys his spare time in the great outdoors.