This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Robin Smith of Dalinghaus Construction, reviews common causes of trip hazards and the repair solution of polyurethane concrete leveling. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec today!

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by Robin Smith of Dalinghaus Construction, reviews common causes of trip hazards and the repair solution of polyurethane concrete leveling. If you're an Alchemy-Spetec customer and you'd like to discuss writing content for our blog, please send an email to marketing@alchemy-spetec today!

Raise your hand if you have ever tripped walking down the sidewalk!

Well you are trippin’ for 1 of 2 reasons:

- You are uncoordinated, and can’t be trusted to walk and chew gum at the same time (that would be me).

OR - Uneven concrete slabs created a trip hazard that you have just fallen victim to!

What causes concrete to shift, become uneven, and cause these trip hazards?

- Expansive clay soil: Expansive clay soil is prone to swelling and shrinking. Changes such as temperature, drought, and moisture causes it to expand and contract...causing the concrete to move.

- Soil compaction: When preparing to build a home, the soil must be moved around, or graded, to create a level base to build upon. If the soils aren’t properly compacted before the concrete is poured, over time, it eventually compresses and can settle. This settlement can cause the concrete to shift.

- Leaking water: If a plumbing or irrigation line springs a leak, it can erode the soil around the concrete, causing it to be unstable.

- Poor drainage: Similar to a leak, improper drainage can also cause erosion.

Concrete removal and replacement can be costly. There is a cost effective solution that can even out those dangerous trip hazards in just 1 day!

Polyurethane concrete leveling to the rescue! Polyurethane concrete leveling, also known as “polyjacking”, is a process in which the contractor drills small holes through the affected sunken slabs. A port is then placed in the hole, the polyurethane is injected as a liquid, then quickly expands to lift the slab back into place.

If you are a visual person like me, check out this video on the Dalinghaus Consruction YouTube channel...

Whether it is a sidewalk, porch, patio, or a VERY busy Orange County Transportation Authority bus stop (insert one more rad video)...

...polyurethane concrete leveling is often an excellent solution, without breaking the bank!

Click here for more information on Dalinghaus Construction.

This post is part of the

This post is part of the

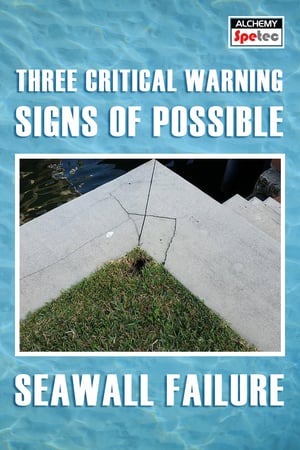

Storms, tidal action, and soil erosion constantly cause damage to seawalls. It is essential to identify any problems as early as possible. Here are the most common warning signs of seawall failure:

Storms, tidal action, and soil erosion constantly cause damage to seawalls. It is essential to identify any problems as early as possible. Here are the most common warning signs of seawall failure:

For hand sanitizers, the CDC website recommends a >60% ethanol, or >70% isopropyl version in healthcare settings. However, the CDC is only one agency. Comparatively speaking, the FDA will adhere to their own claims as to what is acceptable in healthcare, food processing, home use etc. And within each of these segments, there will be different approvals for different uses. For instance, a poultry plant will require specific claims to the efficacy to kill salmonella. The resulting EPA claim registration will be different for the chemical used to clean a cleaver to butcher a chicken compared to a surface on which the chickens are stored. In addition to this, the same product may have registered claims to kill 99.9% salmonella in 60 seconds, while another producer had the same claim, for the same chemical, approved with a 90-second kill claim. These could be different products at the retail level. Also, EPA approval does not constitute FDA approval, and vice versa. It’s easy to see that agency regulations can be very confusing.

For hand sanitizers, the CDC website recommends a >60% ethanol, or >70% isopropyl version in healthcare settings. However, the CDC is only one agency. Comparatively speaking, the FDA will adhere to their own claims as to what is acceptable in healthcare, food processing, home use etc. And within each of these segments, there will be different approvals for different uses. For instance, a poultry plant will require specific claims to the efficacy to kill salmonella. The resulting EPA claim registration will be different for the chemical used to clean a cleaver to butcher a chicken compared to a surface on which the chickens are stored. In addition to this, the same product may have registered claims to kill 99.9% salmonella in 60 seconds, while another producer had the same claim, for the same chemical, approved with a 90-second kill claim. These could be different products at the retail level. Also, EPA approval does not constitute FDA approval, and vice versa. It’s easy to see that agency regulations can be very confusing.

The INJECTR Series single cartridge houses grout and accelerator in two separate interior compartments. The grout and accelerator are thoroughly blended when injected through the static mixer. This cartridge is compatible with standard caulk guns.

The INJECTR Series single cartridge houses grout and accelerator in two separate interior compartments. The grout and accelerator are thoroughly blended when injected through the static mixer. This cartridge is compatible with standard caulk guns.

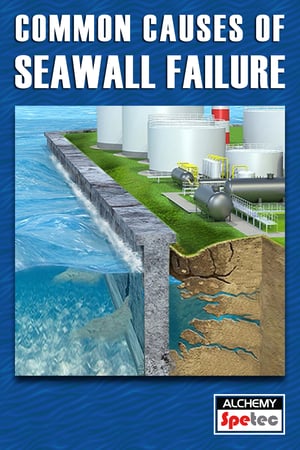

Seawalls are built to create a strong and stable barrier between a body of water and adjacent land, but why do they fail over time? Here are three common factors that can damage a seawall.

Seawalls are built to create a strong and stable barrier between a body of water and adjacent land, but why do they fail over time? Here are three common factors that can damage a seawall.

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

Alchemy-Spetec is pleased welcome Colt Hullander! Colt will join us as the new Director of Technical Services – Geotech Division, supporting Alchemy-Spetec customers on a wide variety of polyurethane jobs, from slab lifting to soil stabilization and seawall repair. He brings a decade of geotech experience to the team.

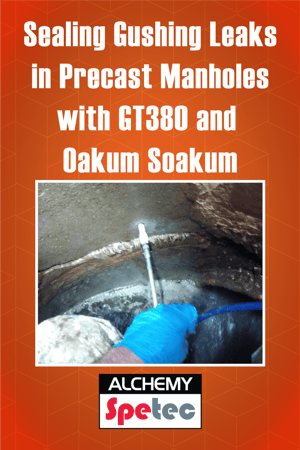

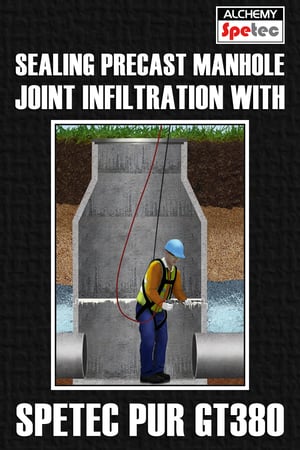

Major water infiltration in precast manholes often occurs at the pipe penetrations. Failure to seal these leaks quickly could lead to the loss of thousands of dollars. It can also suck in soils and fine particlesThis process creates voids outside the manhole. With time, these voids grow larger and become sinkholes.

Major water infiltration in precast manholes often occurs at the pipe penetrations. Failure to seal these leaks quickly could lead to the loss of thousands of dollars. It can also suck in soils and fine particlesThis process creates voids outside the manhole. With time, these voids grow larger and become sinkholes.

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

In this post, we’re profiling

In this post, we’re profiling