Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.

Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.

Give Yourself Plenty of Room to Stop and Turn

When towing a trailer, the distance required to stop is more than most people realize. The amount of space between you and the vehicle in front of you must be doubled if not more compared to driving without a trailer. The same is true with turns. Allow more space than you think you may need between you and any curbs or other vehicles. And don't jackknife the trailer (a turn so sharp that it touches your bumper) as this can cause damage.

Keep Your Trailer Grounded

Winds, downhill grades, and momentum can all lead to trailer swaying. We recommend utilizing a hitch stabilization device to negate some of these effects. You can also release the gas pedal and manually apply the trailer brakes with a brake controller as needed. Your trailer can start swinging back and forth behind you if you are not monitoring your surroundings and speed.

Look Twice While Changing Lanes

Your blind spots significantly increase with a trailer and it’s much harder to make quick lane changes. Give yourself plenty of space and move slowly from one lane to the other after double-checking your blind spots and the positions of surrounding vehicles.

Patience is Key with Passing

You also have to allow more distance and time when passing other vehicles. Give yourself plenty of room to get your vehicle safely up to speed with the trailer in tow. Be patient and remain calm at all times, even when other drivers may impatiently speed up and pass you.

Avoid Blocking Yourself In

Just because you can get in doesn’t mean you can get out. It’s a lot easier to get stuck or blocked in with a trailer than most people realize. Make sure there's plenty of space to make a complete turnaround or choose a spot where you can exit straightaway.

Practice Backing Up with the Trailer

Backing up with a trailer can be counter-intuitive for newbies. New trailer drivers should take some time in a parking lot or other spacious area to practice slowly driving in reverse. You’ll find that you have to turn the steering wheel left in order to move the trailer towards the right and vice versa. For most people it doesn’t feel right at first, so it’s definitely worth practicing in a safe environment.

Perform Regular Maintenance and Carry a Spare Tire

If you have electric brakes on the trailer, be sure to calibrate them so they are receiving the correct amount power. Follow the calibration procedures in your brake controller manual. Check the lug nuts with a lug wrench periodically to make sure they aren't coming loose. Grease the bearings on the axels every 10,000 miles or once a year, whichever comes first. Carry a spare tire, a lug wrench, and a jack that is strong enough to lift your trailer. It's tough to change a tire without the proper equipment.

Stay Alert

The #1 reason people get into accidents is because they are not paying attention, driving faster than they should, or simply lacking foresight. Look further down the road than you normally would because it takes longer to speed up, brake, change lanes, and turn with a trailer. This way you can spot and anticipate problems from a mile away.

Want more information on geotech products and equipment?

How to Sell Using Explainer Animations

How to Sell Using Explainer Animations

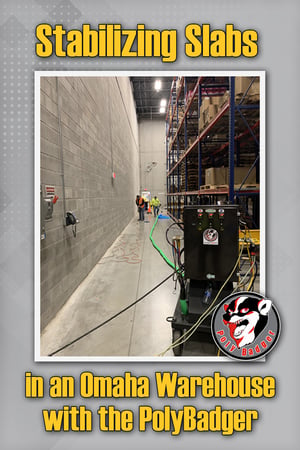

Not too long ago, I visited my customer Melvin Sudbeck’s company, Sudbeck Construction, on a warehouse job. They were called in by the property owner because he had noticed four slabs that were shifting up and scraping against a wall when forklifts crossed them. The crew drilled a couple of preliminary holes in the slabs for diagnostic purposes and discovered voids underneath ranging from 12-18 inches in depth.

Not too long ago, I visited my customer Melvin Sudbeck’s company, Sudbeck Construction, on a warehouse job. They were called in by the property owner because he had noticed four slabs that were shifting up and scraping against a wall when forklifts crossed them. The crew drilled a couple of preliminary holes in the slabs for diagnostic purposes and discovered voids underneath ranging from 12-18 inches in depth.

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

Precision Concrete Leveling

Precision Concrete Leveling

Alchemy-Spetec is excited to welcome Brian Oeder as Vice President of Sales and Marketing. Brian brings with him over 25 years of experience in manufacturing and growth-oriented companies. He has extensive business experience in over 30 countries across 6 continents, due to his leadership positions at two internationally based companies. He has served a wide variety of clients in industries such as petrochemical, oil & gas, mining, and automotive. His diverse background includes management of marketing and sales teams, service, internal support, and training. He especially enjoys on-site technical support and managing technical support professionals. Brian holds degrees in International Business and Marketing from Ohio State University, and a Master of Business Administration from Xavier University. He resides in Cincinnati, Ohio with his wife and three children.

Alchemy-Spetec is excited to welcome Brian Oeder as Vice President of Sales and Marketing. Brian brings with him over 25 years of experience in manufacturing and growth-oriented companies. He has extensive business experience in over 30 countries across 6 continents, due to his leadership positions at two internationally based companies. He has served a wide variety of clients in industries such as petrochemical, oil & gas, mining, and automotive. His diverse background includes management of marketing and sales teams, service, internal support, and training. He especially enjoys on-site technical support and managing technical support professionals. Brian holds degrees in International Business and Marketing from Ohio State University, and a Master of Business Administration from Xavier University. He resides in Cincinnati, Ohio with his wife and three children.

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article is an excerpt from

This article features intros and links to our top 5 most popular seawall repair blogs:

This article features intros and links to our top 5 most popular seawall repair blogs:

Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.

Whether it’s your first time or you’re a seasoned veteran, this guide can serve as a simple checklist to keep your equipment and 16-20 foot trailer safe as you travel to your next project.