Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

Polyurethane grouting is an essential process in construction and infrastructure projects with the need to lift structures, fill voids, and stabilize soil. While polyurethane grouting has been utilized for decades, advancements in technology and technique have enabled a new level of precision and control in modern grouting applications. Innovations in polyurethane injection methods and equipment allow design and construction teams to achieve highly accurate, consistent injections for maximum strength and longevity.

Precision is critical in polyurethane grouting applications. Inadequate filling of voids or inconsistent distribution of grout can lead to structural instability, settlement, and even collapse. Precise injections ensure that soil is saturated, voids are filled, and slabs are leveled accurately. This provides uniform load distribution and protection against shifting, vibration, and erosion. Precision also prevents wasted materials and rework due to incorrect amounts or placement of grout.

Modern polyurethane grouting equipment and techniques enable accurate monitoring and adjustment of grout injection rates, depths, pressures, and consistency. Some examples of modern technology include:

- Hydraulic and Electric Pumps: Modern polyurethane injection equipment includes hydraulic or electric pumps. These pumps provide precise control over pressure and flow, ensuring a more uniform injection of grout material.

- High-Pressure Injection: Modern equipment can handle high-pressure injection, making it suitable for stabilizing deep structures and addressing challenging soil conditions. High-pressure injection ensures better penetration of the polyurethane grout.

- Remote Monitoring and Data Logging: Advanced systems come with remote monitoring and data logging capabilities when necessary. Operators can monitor the injection process remotely and collect data on pressure, flow, and other parameters for quality control and documentation.

- Compact and Portable Systems: Some advanced injection grouting systems are designed to be compact and portable, making them easier to transport to job sites and set up quickly.

- Safety Features: Modern equipment includes safety features such as shut-off valves and pressure relief mechanisms to protect both operators and the equipment itself.

Modern polyurethane grouting equipment has revolutionized construction and infrastructure project challenges, offering engineers and design teams an array of precision-driven advantages. The evolution of polyurethane injection equipment, including hydraulic pumps, pneumatic pumps, and computerized control systems has empowered design teams and application technicians to achieve precise outcomes.

.jpg?width=1400&height=425&name=Banner%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg)

.jpg?width=300&height=450&name=Body%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg) Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Inflow and Infiltration (I&I)

Inflow and Infiltration (I&I)

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

The approach and departure slabs adjacent to a bridge in McKenzie County, North Dakota had settled, leading to an uneven and hazardous road surface. A geotechnical contractor was brought in to level the road surface and mitigate any further settlement.

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

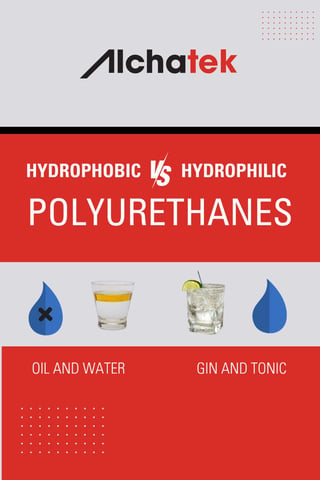

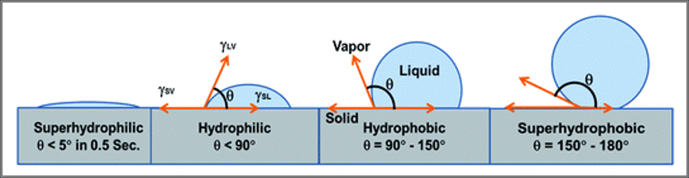

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

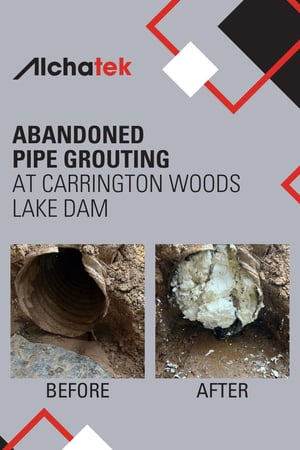

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

Carrington Woods Lake Dam is located in Baldwin County, Georgia. A consulting firm collaborating with a general contractor called in geotech specialists

When the residue of plants or animals is converted into soil, the process is known as decomposition. Bacteria, fungi, and worms break down this residue, taking nutrients from them and leaving the remaining portion. Organic molecules are broken down into simpler inorganic molecules. This biological process changes the makeup of the soil and can therefore lead to soil instability.

When the residue of plants or animals is converted into soil, the process is known as decomposition. Bacteria, fungi, and worms break down this residue, taking nutrients from them and leaving the remaining portion. Organic molecules are broken down into simpler inorganic molecules. This biological process changes the makeup of the soil and can therefore lead to soil instability.