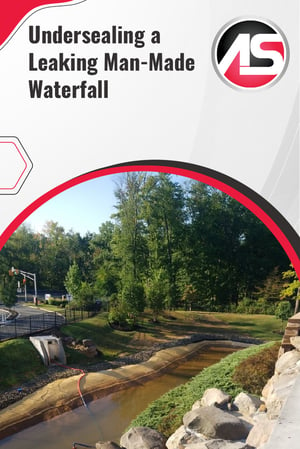

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was constructed to continuously pump water from the pond below to the very top, so it could flow back down over the rocks. Over time, leaks and voids began to form through the entirety of the structure due to erosion. The structure itself started to settle as the water began washing out the soil underneath. In order to remediate the problem, the contractor advised undersealing the entire structure to seal it and fill voids underneath. This process would stabilize the entire structure and prevent any further movement.

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was constructed to continuously pump water from the pond below to the very top, so it could flow back down over the rocks. Over time, leaks and voids began to form through the entirety of the structure due to erosion. The structure itself started to settle as the water began washing out the soil underneath. In order to remediate the problem, the contractor advised undersealing the entire structure to seal it and fill voids underneath. This process would stabilize the entire structure and prevent any further movement.

Powerful Polymer

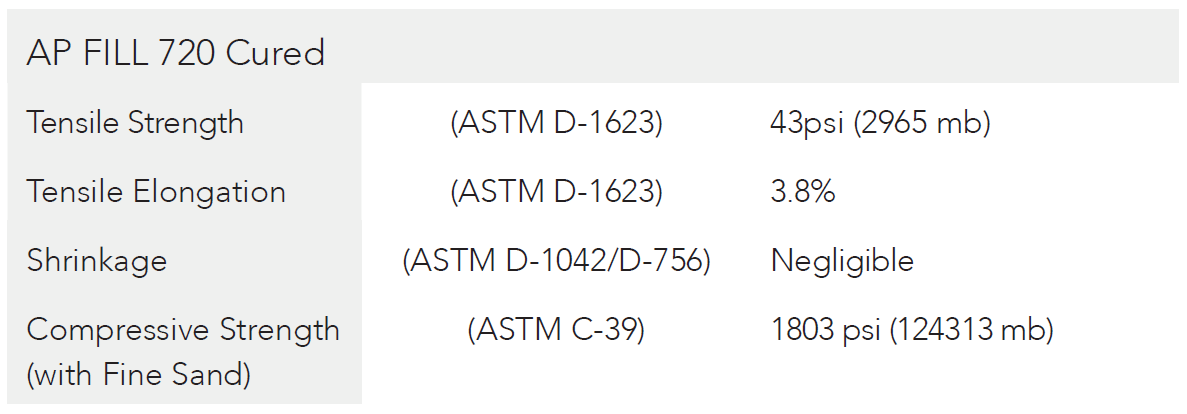

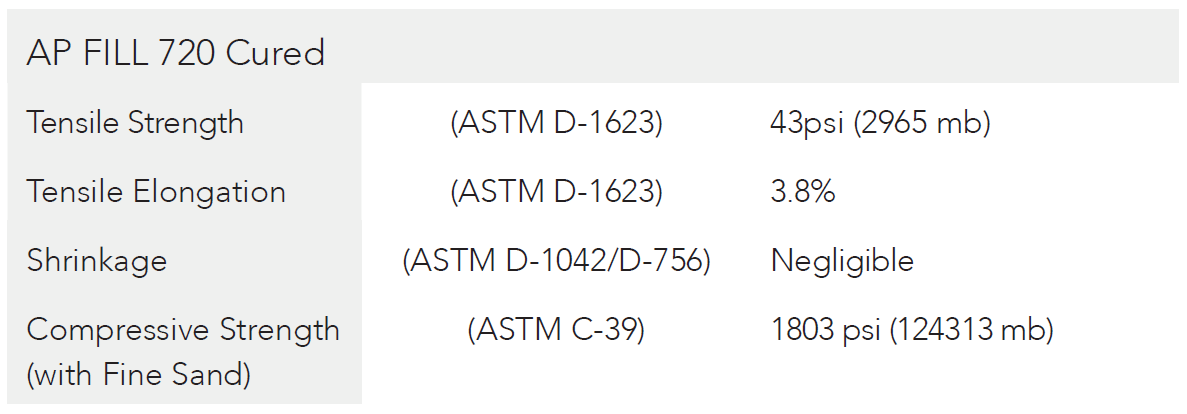

To complete the job, the contractor selected Alchemy-Spetec's AP Fill 720 structural polymer due to its ability to permeate and encapsulate loose supporting soil into one solid mass. This material is a single component, closed cell, hydrophobic, water-reactive, solvent and phthalate-free, low-viscosity polyurethane injection resin for stabilizing soil and filling voids around structures (cutting off any existing leaks in the process).

Painless Procedure

The crew drilled small holes, installed injection ports, and injected the material into the soil below, every four feet, eventually creating a grid pattern across the entire structure. They started this process at the top of the structure and worked their way to the bottom, injecting the material into each spot until the void was full (a.k.a. grouted to refusal).

Rapid Result

From the start of the project, planning, and evaluation took about a month. Once the injection plan was in place, the crew completed the job in just a day and a half with a four-man crew. The man-made waterfall is now leak free and will continue to see decades of further use.

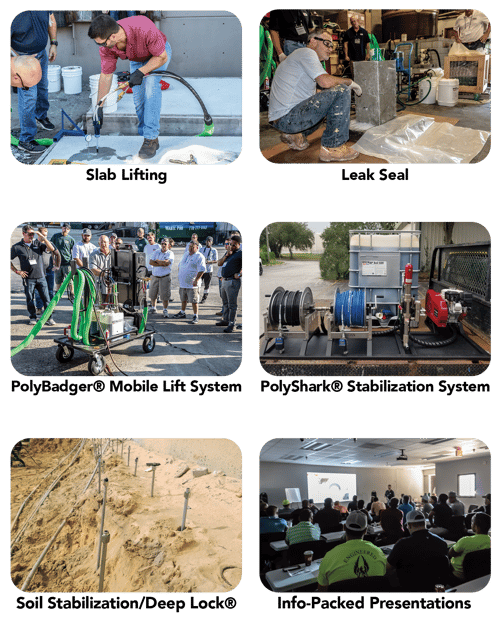

Want more information about Soil Stabilization?

May 2nd - May 4th

May 2nd - May 4th

Premier On-The-Job Technical Support

Premier On-The-Job Technical Support

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was

A geotech contactor was called to Livingston, NJ to evaluate a settling man-made waterfall. The waterfall was

The Problem

The Problem

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks,

Single component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin for stabilizing soil. Also good for filling voids and cutting off high-flow underground leaks,