.png?width=1024&name=elevator-banner%20(1).png)

.png?width=320&name=elevator-blog%20(2).png) Elevator pit water leaks are very common. These pits can be open to flooding and leakage because they are usually at the lowest point of a building below the water table. Water can easily seep from cracks in the walls or through the floor wall detail.

Elevator pit water leaks are very common. These pits can be open to flooding and leakage because they are usually at the lowest point of a building below the water table. Water can easily seep from cracks in the walls or through the floor wall detail.

There are many reasons why elevator pits leak. This can include incorrect application, damage to existing elevators, pits that are very old, changes in the water table, and even shortcuts that have been taken such as non-installation of waterproofing materials. These are just a few of the causes.

So what happens when these elvator pits become consumed with water?

The solution is simple!

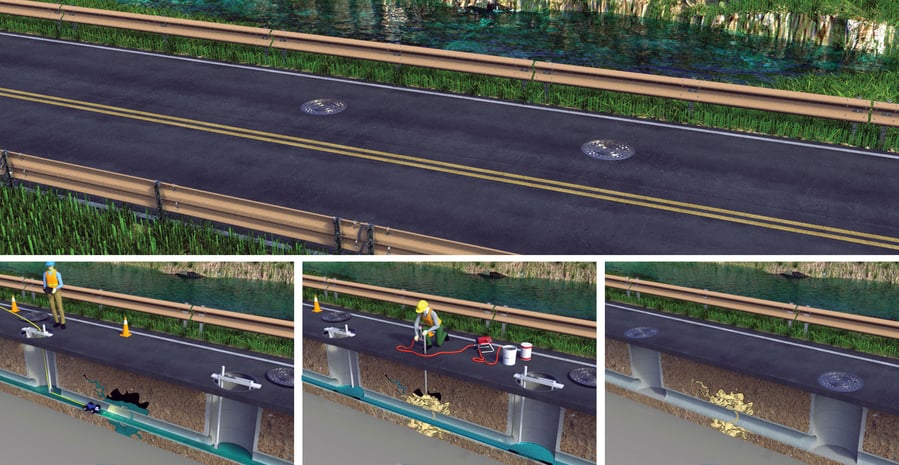

You would drill holes through the walls and floor using a grid pattern. You would then pump water activated polyurethane chemical grout into the soil to create what we call a “curtain wall”. This wall essentially stops the water from penetrating the area around the pit. It creates a permanent seal and allows the elevator to function properly again. (If you're a property owner, we can help you find a contractor to do this. Just call us at 404-618-0438.)

Alchemy-Spetec products that are used for curtain wall grouting include:

| Spetec PUR H100 |

| AP Fill 700 |

| Spetec AG200 |

If you are unfamiliar with the term "curtain wall" and what it includes, be sure to check out our previous blog series on Curtain Wall Grouting to gain a deeper understanding of the process.

Want more information on curtain wall grouting?

Polyurethane chemical grouts fall into two categories when it comes to how they relate with water: hydrophilic and hydrophobic.

Polyurethane chemical grouts fall into two categories when it comes to how they relate with water: hydrophilic and hydrophobic.

.png?width=899&height=273&name=THE%20EFFECTS%20OF%20TEMPERATURE-%20banner%20(3).png)

.png?width=320&name=THE%20EFFECTS%20OF%20TEMPERATURE-%20blog%20(4).png) Condition the Materials

Condition the Materials

.png?width=899&height=273&name=culvert%20repair-%20social%20(3).png)

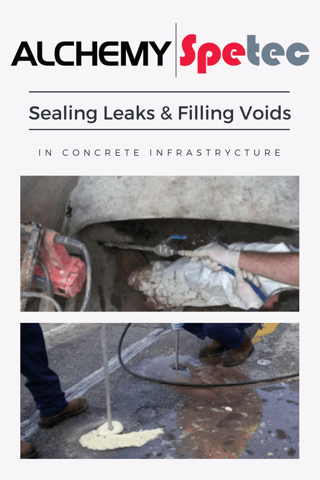

-1.png?width=320&name=culvert%20repair-%20social%20(2)-1.png) AP Fill 700 is a single component polyurethane injection resin that reacts when it comes into contact with water or moisture. It can be premixed with a catalyst which will make the resin react as a foam to fill voids or shut off leaks. It can also be injected without a catalyst as a pure permeation resin to stabilize soil.

AP Fill 700 is a single component polyurethane injection resin that reacts when it comes into contact with water or moisture. It can be premixed with a catalyst which will make the resin react as a foam to fill voids or shut off leaks. It can also be injected without a catalyst as a pure permeation resin to stabilize soil.

.png?width=899&height=273&name=Distributor%20Profile%20Series-%20(2).png)

-1.png?width=320&name=Distributor%20Profile%20Series-%20(1)-1.png) In this article, we feature

In this article, we feature .png?width=899&height=273&name=concrete%20crack-banner%20(1).png)

I recently consulted with

I recently consulted with .png?width=899&height=273&name=Twin%20Streaming%20(2).png)

Advantages:

Advantages:

As Andy Powell states in his post:

As Andy Powell states in his post: