I recently had the opportunity to train a crew on a very interesting job inside an underwater utility tunnel beneath a lock and dam in the St. Lawrence Seaway. This seaway connects the Great Lakes to the Atlantic Ocean. This tunnel is underneath a giant concrete deck, so the walls have taken a lot of pressure over time. The soil also shifts and settles underneath the tunnel as the years go by. Those factors, in addition to freeze/thaw cycles have caused cracks to appear in the walls.

One particularly large crack was 20 feet long and up to 2 inches wide in some places. The water leaking through created an especially dangerous situation considering the 480 volt electrical box you can see in the photo above. There is also plenty of valuable equipment in the tunnel that is susceptible to water damage.

I suggested to the customer that they buy about four 5 gallon pails of Spetec F400. I recommended this material because it works very well in wet joints and cracks. It also remains somewhat flexible after installation, so if the walls settle or shift a little more, the cured grout will not break. When I showed up we got to work immediately with our on-the-job training, using modified airless sprayers to pump the material. Overall, it took about 2.5 hours for the crew to get the job done while learning the leak seal process at the same time.

.png?width=320&name=Curtain%20Wall%20Grouting-blog%20(3).png) Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

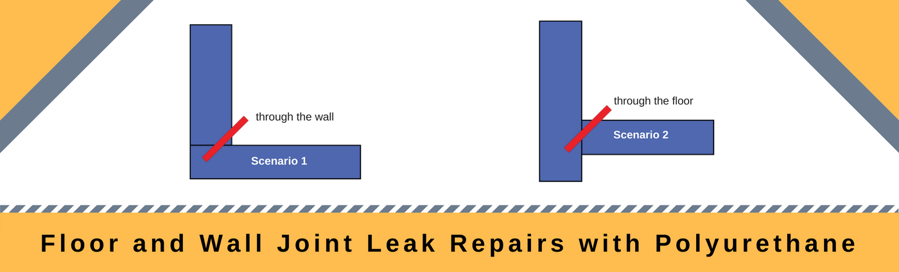

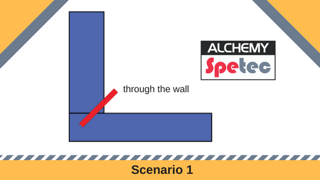

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.-1.png?width=320&name=floor%20wall-%20blog%20(1)-1.png) In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.

In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.

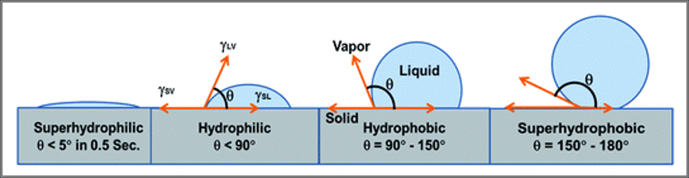

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Northgate Link Extension with GT350

Northgate Link Extension with GT350

Alternately, oakum can be soaked in

Alternately, oakum can be soaked in

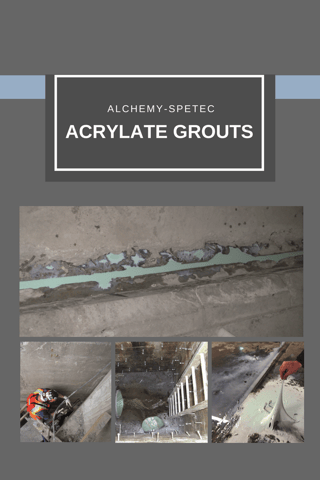

Acrylates were introduced in the early 80s to the waterproofing industry as a less toxic alternative to

Acrylates were introduced in the early 80s to the waterproofing industry as a less toxic alternative to

What Can You Do?

What Can You Do?