.png?width=300&name=Sealing%20Leaks%20in%20Elevator%20Pits%20(1).png)

Elevator pit water leaks are very common. These pits can be open to flooding and leakage because they are usually at the lowest point of a building below the water table. Water can easily seep from cracks in the walls or through the floor wall detail.

There are many reasons why elevator pits leak. This can include incorrect application, damage to existing elevators, pits that are very old, changes in the water table, and even shortcuts that have been taken such as non-installation of waterproofing materials. These are just a few of the causes.

So what happens when these elevator pits become consumed with water?

The solution is simple!

You would drill holes through the walls and floor using a grid pattern. You would then pump water activated polyurethane chemical grout into the soil to create what we call a “curtain wall”. This wall essentially stops the water from penetrating the area around the pit. It creates a permanent seal and allows the elevator to function properly again. (If you're a property owner, we can help you find a contractor to do this. Just call us at 404-618-0438.)

Alchemy-Spetec products that are used for curtain wall grouting include:

Want more information on curtain wall grouting?

Topics:

All Posts,

Seal Leaks

.png?width=899&name=2019%20Fall%20Training%20on%20Oct%209th%20%26%2010th%20-%20Register%20Before%20the%20Sep%2025th%20Deadline!%20(1).png)

.png?width=300&name=2019%20Fall%20Training%20on%20Oct%209th%20%26%2010th%20-%20Register%20Before%20the%20Sep%2025th%20Deadline!%20(2).png)

Register NOW before the September 25th deadline!

October 9th & 10th, 2019 at Alchemy-Spetec HQ in Tucker, GA

Get ready for a thorough education in Leak Seal, Slab Lifting, Soil Stabilization and the Alchemy-Spetec Deep Lift™ process. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Wednesday - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Thursday - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Participants receive a Samsung tablet loaded with training material.

Your Instructors:

Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), Charlie Lerman (Western Regional Manager), and Michael Binyaminov (Western Sales Representative).

Topics:

Repair Seawalls,

Equipment & Accessories,

All Posts,

Lift Slabs,

NSF Certification,

Seal Leaks,

Stabilize Soil,

Business Tips,

Repair Cracks,

Waterstop,

Deep Lift,

Floor Repair,

Fill Voids,

Engineer Resources

-2.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1)-2.png)

You still have a chance to sign up for Fall 2019 Training while there are still spots left. Don't miss this critical opportunity to turbo-charge your business!

October 9th & 10th, 2019 at Alchemy-Spetec HQ in Tucker, GA

Get ready for a thorough education in Leak Seal, Slab Lifting, Soil Stabilization and the Alchemy-Spetec Deep Lift™ process. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Wednesday - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Thursday - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Participants receive a Samsung tablet loaded with training material.

Your Instructors:

Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), Charlie Lerman (Western Regional Manager), and Michael Binyaminov (Western Sales Representative).

Topics:

Repair Seawalls,

Equipment & Accessories,

All Posts,

Lift Slabs,

NSF Certification,

Seal Leaks,

Stabilize Soil,

Business Tips,

Repair Cracks,

Waterstop,

Deep Lift,

Floor Repair,

Fill Voids,

Engineer Resources

-1.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1)-1.png)

Sign up for Fall 2019 Training while there are still spots left!

October 9th & 10th, 2019 at Alchemy-Spetec HQ in Tucker, GA

Get ready for a thorough education in Leak Seal, Slab Lifting, Soil Stabilization and the Alchemy-Spetec Deep Lift™ process. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Wednesday - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Thursday - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Participants receive a Samsung tablet loaded with training material.

Your Instructors:

Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), Charlie Lerman (Western Regional Manager), and Michael Binyaminov (Western Sales Representative).

Topics:

Repair Seawalls,

Equipment & Accessories,

All Posts,

Lift Slabs,

NSF Certification,

Seal Leaks,

Stabilize Soil,

Business Tips,

Repair Cracks,

Waterstop,

Deep Lift,

Floor Repair,

Fill Voids,

Engineer Resources

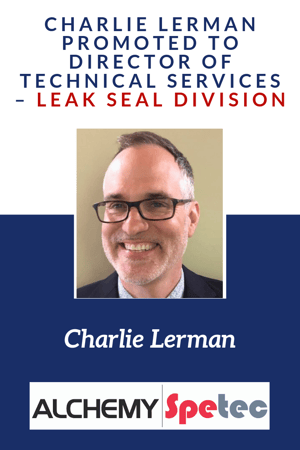

Alchemy-Spetec is proud to announce that Charlie Lerman "The Grout Geek" will be shifting roles to start up our North American Leak Seal Technical Services Department. Charlie not only brings two decades of specialty waterproofing and construction experience to his new role as Director of Technical Services - Leak Seal Division, but he also brings nine years of service in the US Navy. He understands the value of teamwork and is dedicated to the mission.

Alchemy-Spetec is proud to announce that Charlie Lerman "The Grout Geek" will be shifting roles to start up our North American Leak Seal Technical Services Department. Charlie not only brings two decades of specialty waterproofing and construction experience to his new role as Director of Technical Services - Leak Seal Division, but he also brings nine years of service in the US Navy. He understands the value of teamwork and is dedicated to the mission.

While the trend in the last few years for chemical grout manufacturers has been to reduce or eliminate their technical service roles, Alchemy-Spetec understands the needs of the specialty waterproofing contractor and is committed to customer success. Leveraging Alchemy-Spetec’s quality products, strong distribution, and our rapid response technical service is what gives our contractors the edge they need in today's fast-paced market.

Please let us know how we can assist you with your next waterproofing challenge. Whether you need help with product selection, hands-on field training, or creative grouting solutions, Alchemy-Spetec is here for you.

Want more information on Alchemy-Spetec leak seal products?

Topics:

All Posts,

Seal Leaks,

Waterstop

.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(2).png)

.png?width=300&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1).png) Don't forget to sign up for Fall 2019 Training!

Don't forget to sign up for Fall 2019 Training!

October 9th & 10th, 2019 at Alchemy-Spetec HQ in Tucker, GA

Get ready for a thorough education in Leak Seal, Slab Lifting, Soil Stabilization and the Alchemy-Spetec Deep Lift™ process. You’ll get hands-on training from a technical staff with decades of on-the-job experience.

Wednesday - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Thursday - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Participants receive a Samsung tablet loaded with training material.

Your Instructors:

Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), Charlie Lerman (Western Regional Manager), and Michael Binyaminov (Western Sales Representative).

Topics:

Repair Seawalls,

Equipment & Accessories,

All Posts,

Lift Slabs,

NSF Certification,

Seal Leaks,

Stabilize Soil,

Business Tips,

Repair Cracks,

Waterstop,

Deep Lift,

Floor Repair,

Fill Voids,

Engineer Resources

.png?width=899&name=Polyurethane%20Leak%20Sealing%20Explained%20(3).png)

Leaking concrete can be detrimental to safety and property values. Pressure injection forces polyurethane resin into leaking cracks, joints, voids, and other defects. After injection is complete, the polyurethane resin rapidly reacts with water to form a flexible, watertight seal. Leaks in concrete structures can be permanently repaired with water-activated polyurethane and a few assorted leak seal accessories.

From hairline concrete cracks to gushing leaks, virtually any defect can be sealed with the Alchemy-Spetec series of leak seal resins and products.

Watch this animation for a detailed explanation of the polyurethane leak sealing process...

Want more information on Alchemy-Spetec leak seal products?

Topics:

All Posts,

Seal Leaks,

Waterstop

-1.png?width=300&name=Jump%20Start%20Your%20New%20Concrete%20Leveling%20Business%20with%20Alchemy-Spetecs%20Fall%202019%20Training%20(1)-1.png) Jump start your leak seal business at Alchemy-Spetec's Fall 2019 Training! As stated in our blog post on Leak Seal Curriculum for 2019 Fall Training...

Jump start your leak seal business at Alchemy-Spetec's Fall 2019 Training! As stated in our blog post on Leak Seal Curriculum for 2019 Fall Training...

Get ready for a thorough education in polyurethane leak seal products and applications on Wednesday, October 9th (October 10th is geotech day), 2019 at Alchemy-Spetec HQ in Tucker, GA. You’ll get hands-on training from a technical staff with decades of on-the-job experience. Registration includes both days, but we’ll take a close look at the leak seal curriculum in today’s blog post…

The schedule on Wednesday, October 9th includes presentations on the Alchemy-Spetec leak seal product line, crack injection, curtain grouting, permeation grouting, pumps & packers, leak seal accessories and municipal applications. There will also be live injection demos, product mixing demos, and open discussions for sharing job related tips and solutions from the field.

In addition, you'll get an overview of geotech (concrete leveling & soil stabilization) products and procedures! Here's a complete schedule for both days...

Wednesday Oct. 9th - Leak Seal

- Leak Seal Product Line Overview

- Curtain Grouting

- Permeation Grouting

- Leak-Seal Product Mixing

- Pump & Packer Overviews

- Leak-Seal Accessories

- Municipal Applications

- Live Injection Demos

- Open Discussions

Thursday Oct. 10th - Geotech

- Geotech Product Line Overview

- Soil Stabilization

- Geotech Product Mixing

- Rig & Mobile System Overviews

- Geotechnical Accessories

- Slab Lifting Live Demo

- Deep Lift™ Overview

- Soil Testing with the

- GPR & Penetrometer

- Maintenance Discussions

- Pricing / Estimating / Cost Savings

- Open Discussions

Topics:

All Posts,

Seal Leaks,

Business Tips

.png?width=1400&name=banner%20Specifications%20for%20Polyurethane%20Injection%20Grouting%20with%20Hydrophilic%20%26%20Hydrophobic%20Materials%20(1).png)

.png?width=300&name=blog%20Specifications%20for%20Polyurethane%20Injection%20Grouting%20with%20Hydrophilic%20%26%20Hydrophobic%20Materials%20(1).png)

In this blog post, we’ll take a look at our specification entitled Injection Grouting – Hydrophilic & Hydrophobic. The specification includes documentation on the following:

- Sealing cracks in concrete structures through pressure injection.

- Sealing hairline cracks, expansion joints, wide cracks, pipe joints, pipe penetrations.

- Saturating dry oakum to create a flexible gasket for sealing pipe penetrations, joints and larger defects in concrete structures.

If you’re unfamiliar with the terms hydrophobic and hydrophilic, please read the blog post Hydrophobic vs Hydrophilic Polyurethanes. In that post we clearly explain the differences between the two types of leak seal resins…

Hydrophobic Polyurethanes:

Hydrophobic polyurethanes naturally repel water (similar to the way oil would repel water and stay separate if you were trying to mix them in a glass). These products push water out of the area in question as they expand. Hydrophobics are used with catalysts which allow you to adjust the set time. They also have zero shrinkage after curing.

Hydrophilic Polyurethanes:

Hydrophilic polyurethanes naturally mix with water before curing (similar to the way gin and tonic mix thoroughly in a glass). This characteristic allows for a very strong chemical and mechanical bond, as water helps pull the material into the pores of the concrete. These products do not require a catalyst. You can pump them straight out of the pail.

Click this link, Injection Grouting – Hydrophilic & Hydrophobic, to view a PDF of the specification. It thoroughly documents the installation process for these two types of products (in our case, the hydrophilic Spetec PUR GT500 and the hydrophobic Spetec PUR F400). These are both flexible polyurethanes. For a copy of the specification in Microsoft Word format, please call Alchemy-Spetec at 404-618-0438.

For more Alchemy-Spetec specifications, scroll to the bottom of the Alchemy-Spetec Downloads Page.

Would you like to speak to an Alchemy-Spetec consultant regarding specifications?

Topics:

All Posts,

Seal Leaks,

Engineer Resources

Get ready for a thorough education in polyurethane leak seal products and applications on Wednesday, October 9th (October 10th is geotech day), 2019 at Alchemy-Spetec HQ in Tucker, GA. You’ll get hands-on training from a technical staff with decades of on-the-job experience. Registration includes both days, but we’ll take a close look at the leak seal curriculum in today’s blog post…

The schedule on Wednesday, October 9th includes presentations on the Alchemy-Spetec leak seal product line, crack injection, curtain grouting, permeation grouting, pumps & packers, leak seal accessories and municipal applications. There will also be live injection demos, product mixing demos, and open discussions for sharing job related tips and solutions from the field.

Your instructors have years of experience providing technical support for both contractors and distributors across the country. You can look forward to presentations, demos and/or discussions lead by Stephen C. Barton (President/CEO), Jim Spiegel (VP Sales & Business Development), Andy Powell (Southeastern Regional Manager), Anthony Sandone (Eastern Regional Manager), and Charlie Lerman (Western Regional Manager).

Participants will receive a Samsung tablet loaded with leak seal training material.

Sign up while there's still space available...

Topics:

All Posts,

Seal Leaks,

Business Tips

.png?width=300&name=Sealing%20Leaks%20in%20Elevator%20Pits%20(1).png)

.png?width=899&name=2019%20Fall%20Training%20on%20Oct%209th%20%26%2010th%20-%20Register%20Before%20the%20Sep%2025th%20Deadline!%20(1).png)

.png?width=300&name=2019%20Fall%20Training%20on%20Oct%209th%20%26%2010th%20-%20Register%20Before%20the%20Sep%2025th%20Deadline!%20(2).png)

-2.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1)-2.png)

-1.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1)-1.png)

Alchemy-Spetec is proud to announce that Charlie Lerman "The Grout Geek" will be shifting roles to start up our North American Leak Seal Technical Services Department. Charlie not only brings two decades of specialty waterproofing and construction experience to his new role as Director of Technical Services - Leak Seal Division, but he also brings nine years of service in the US Navy. He understands the value of teamwork and is dedicated to the mission.

Alchemy-Spetec is proud to announce that Charlie Lerman "The Grout Geek" will be shifting roles to start up our North American Leak Seal Technical Services Department. Charlie not only brings two decades of specialty waterproofing and construction experience to his new role as Director of Technical Services - Leak Seal Division, but he also brings nine years of service in the US Navy. He understands the value of teamwork and is dedicated to the mission.

.png?width=1400&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(2).png)

.png?width=300&name=Reminder%20-%202019%20Fall%20Training%20on%20October%209th%20%26%2010th%20(1).png) Don't forget to sign up for Fall 2019 Training!

Don't forget to sign up for Fall 2019 Training!.png?width=899&name=Polyurethane%20Leak%20Sealing%20Explained%20(3).png)

-1.png?width=300&name=Jump%20Start%20Your%20New%20Concrete%20Leveling%20Business%20with%20Alchemy-Spetecs%20Fall%202019%20Training%20(1)-1.png) Jump start your leak seal business at

Jump start your leak seal business at .png?width=1400&name=banner%20Specifications%20for%20Polyurethane%20Injection%20Grouting%20with%20Hydrophilic%20%26%20Hydrophobic%20Materials%20(1).png)

.png?width=300&name=blog%20Specifications%20for%20Polyurethane%20Injection%20Grouting%20with%20Hydrophilic%20%26%20Hydrophobic%20Materials%20(1).png)