This article is an excerpt from Episode 4 of The Injection Connection, featuring Adam Tracy of A-1 Foundation Crack Repair. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

This article is an excerpt from Episode 4 of The Injection Connection, featuring Adam Tracy of A-1 Foundation Crack Repair. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

Jim: In a more general sense with the chemical grouting industry, what do you think, and I may be putting you on the spot here a little bit, but what do you think is lacking or what could be improved in the industry? Do you have opinions on that? Maybe from a product standpoint, maybe from a service standpoint, from the manufacturer’s side? Do you have any thoughts on that?

Adam: I’ve had a pretty unique entry into this industry because I’m from totally outside of the industry. Even though this is a family business, I actually spent the first ten plus years of my career as a manufacturer rep in the fire protection space. So, I’m coming at this industry as a very different set of eyes. I’m actually an engineer in civil engineering and I would definitely say that it’s a niche industry in a lot of ways, which prevents its usage I think because I don’t think it’s well taught on an educational level and I don’t think the awareness is very high amongst a lot of engineering firms as well.

It’s a process that is unique in a lot of ways but it’s not revolutionary. I think while it’s one tool in the tool belt as we discussed, I think having that in an engineer’s hands is very important because a lot of times solutions that are tried more often or may have a higher success rate on the positive side are just cost prohibitive. And the building is not set up to be able to do that kind of stuff post construction and where chemical grouting is really just the best, most cost-effective, high result solution for that particular application.

I would definitely say that on a commercial level the grouting process needs to have a little bit higher expansion in educational areas to make sure that kids coming out of schools and going in for their PEs and trying to get their feet under them and provide solutions to their clients know that this is a proper solution that is tried and true and is very successful.

In my world, where it’s a lot of residential, that’s half of what my job is on a day to day conversation with a customer is explaining what we’re doing because it’s a lot of black magic in their eyes because it’s something totally different. They were looking for the black spray in the can that you used to spray in the bottom of your screen door boat there, off the shelf as a solution and they‘re trying to figure out why it didn’t work. And really, we’re trying to just educate them a little bit as well.

We’ve had projects in the past where they’ve spent a tremendous amount of time on the specifications and the procedures on how to address an issue. We had a project at a wastewater treatment plant where it’s 24-inch walls, thick walls with rebar everywhere, and they were tall. And they’re just trying, there’s not a lot of experience, there wasn’t a lot of manufacturer help in terms of how to really identify the process to do this successfully. So, when we get in there and we look at the specifications, it’s hobbled together by somebody who’s never seen this process in the real world. It was essentially set up for failure in a lot of ways because the process was wrong for this particular application, and trying to go through change orders of the process was a very difficult situation - just because we knew as a contractor doing it for as long as we have that the amount of time and effort that they were going to be focused on their particular process was going to be set up incorrectly and set up for failure mostly because, again, they had a set of people on this thing who have read about it and were very unaware of the infield techniques that are required to be successful in it, and really just tried to be by the book on it without any sort of experience.

I think that in the industry, there would be a huge benefit across the board in my eyes to really start at the educational level, civil engineering programs, construction management programs, to really focus on that. I think manufacturers have some responsibility as well as contractors to give a two-pronged approach so that people are educated both on the technology itself and the actual application and how it gets done.

Jim: I couldn’t agree more.

Adam Tracy, of

Adam Tracy, of

.png?width=1400&name=Quantifying%20Chemical%20Grouting%20Effectiveness%20(1).png)

This blog post features Episode 2 of Alchemy-Spetec's

This blog post features Episode 2 of Alchemy-Spetec's

.png?width=899&name=Announcing%20QP%20Factor%C2%A0%20(3).png)

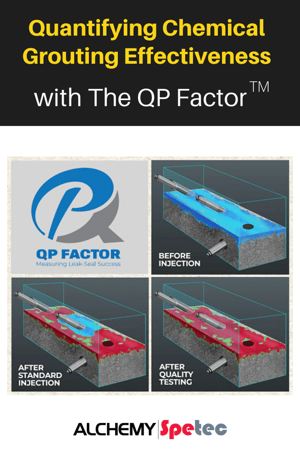

.png?width=300&name=Announcing%20QP%20Factor%C2%A0%20(5).png) In a breaking industry event, Alchemy-Spetec is the first chemical grouting manufacturer to offer the patented Leak Seal quality assurance system, QP Factor

In a breaking industry event, Alchemy-Spetec is the first chemical grouting manufacturer to offer the patented Leak Seal quality assurance system, QP Factor

.png?width=300&name=Announcing%20Spring%202020%20Infrastructure%20Repair%20Training%20(1).png)

.png?width=300&name=Watch%20Educational%20Leak%20Seal%20Presentations%20at%20World%20of%20Concrete%202020%20(3).png)

I just came off my first ever solo field service as a consultant for one of our contractor customers. The story starts as all good ones do...

I just came off my first ever solo field service as a consultant for one of our contractor customers. The story starts as all good ones do... .png?width=899&name=Repairing%20Dams%20with%20Polyurethane%20(5).png)

.png?width=300&name=Repairing%20Dams%20with%20Polyurethane%20(4).png) Dams Across the U.S. in Dire Need of Repair

Dams Across the U.S. in Dire Need of Repair.png?width=1400&name=Slab%20Lifting%20and%20Leak%20Sealing%20in%20Cold%20Weather%20(1).png)

Slab Lifting in Cold Weather

Slab Lifting in Cold Weather.png?width=1400&name=Alchemy-Spetec%20Fall%202019%20Training%20SOLD%20OUT!%20(1).png)

.png?width=300&name=Alchemy-Spetec%20Fall%202019%20Training%20SOLD%20OUT!%20(6).png)