Here it is. My favorite topic. Why? Because it is my pet peeve. It separates the technicians who care from those who are only going through the motions. Quite frankly, it can be the difference between a successful outcome and dismal failure - or at the very least an expensive callback.

Here it is. My favorite topic. Why? Because it is my pet peeve. It separates the technicians who care from those who are only going through the motions. Quite frankly, it can be the difference between a successful outcome and dismal failure - or at the very least an expensive callback.

When you drill holes you create concrete dust. The hammer drill bit literally chews up the concrete. Most of it comes out of the hole and falls on the floor. However, a lot of dust is left behind inside the hole. If it is not properly flushed out then it will mix with your polyurethane injection resin and make a thick paste. This thick paste can be forced into the crack and prevent the clean resin from reaching deep into the crack where it is needed. Most of the time you won’t even realize you have a problem. But there it is nonetheless. Waiting for the right conditions to allow water to seep back through the crack you thought you fixed.

How do you avoid this? Simple - flush the hole out from the back using a very cheap flexible hose that attaches to your flush pump (you did bring a separate flush pump didn’t you?). Start at the highest hole and work your way down until clean water is flowing out of each hole.

Spraying water on the face of the holes may make it look clean, but it is not effective. There is still dust deep in the hole. Filling a water bottle up and squeezing it so that water shoots part way up the hole is not good enough. You have to have the water exit your hose at the back of the hole. This is the only way.

Are there exceptions? Of course, there are. If you pull the drill bit out of the hole and water gushes out behind it in a steady stream you can skip this step. Otherwise, make sure you bring a flush hose with you. It has to be small enough to fit inside your drill hole. We make it easy for you. We make one and sell it for cheap (so don’t blame us if you get to your job site and don’t have one).

This is so basic it is silly. However, I have seen experienced technicians do the water bottle trick and try to explain that it is sufficient. I’m happy to report that those guys are working for your competitors now. Just make sure your guys don’t get lulled into laziness and skip what just might be the most important of these five basic steps:

- Drill the hole

- Flush the hole

- Install the ports

- Flush the crack

- Inject the resin

Next up, we install the ports!

5 Steps of Crack Injection - Overview

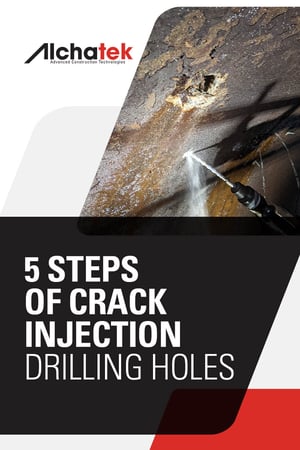

5 Steps of Crack Injection - 1. Drilling Holes

5 Steps of Crack Injection – 1. Drilling Holes (Continued)

5 Steps of Crack Injection – 2. Flushing Holes

5 Steps of Crack Injection – 3. Installing Ports

5 Steps of Crack Injection – 4. Flushing Cracks

5 Steps of Crack Injection – 5. Injecting Resin

Want in-depth info on crack injection procedures and products?

.jpg?width=1400&height=425&name=Banner%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg)

.jpg?width=300&height=450&name=Body%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg) Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Inflow and Infiltration (I&I)

Inflow and Infiltration (I&I)

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

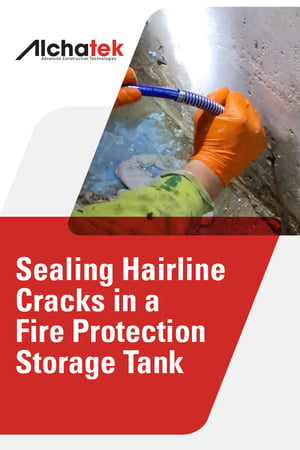

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

There are five basic steps to be done when placing a crack injection. This is crack injection 101. Learn these steps and you will be well on your way to understanding what it takes to seal a water leak in concrete with products such as

If you're a leak seal contractor, you may be familiar with this situation: A property owner with leaking concrete calls you up and says, "Hey, everything is dry right now, so I want to get someone out here to go ahead and waterproof the structure." Attempting a waterproofing job when the structure is completely dry is not recommended.

If you're a leak seal contractor, you may be familiar with this situation: A property owner with leaking concrete calls you up and says, "Hey, everything is dry right now, so I want to get someone out here to go ahead and waterproof the structure." Attempting a waterproofing job when the structure is completely dry is not recommended.

Polyurethane grouting is a complex process that involves numerous specifications and guidelines. However, amidst the vast amount of information, there are five fundamental rules that lie at the core of all successful polyurethane grouting projects. We will explore these rules, highlighting their significance in achieving desired outcomes.

Polyurethane grouting is a complex process that involves numerous specifications and guidelines. However, amidst the vast amount of information, there are five fundamental rules that lie at the core of all successful polyurethane grouting projects. We will explore these rules, highlighting their significance in achieving desired outcomes.

In this article, we’re comparing the use of epoxies and polyurethanes for waterproofing. This is not a battle of good versus evil, but rather a discussion about their differences and when to use each type of material.

In this article, we’re comparing the use of epoxies and polyurethanes for waterproofing. This is not a battle of good versus evil, but rather a discussion about their differences and when to use each type of material.

“At what pressure am I going to inject the grout?” This question is not only common but also crucial on leak seal jobs, as it directly impacts the quality of your work. The answer, however, is not as straightforward as one might hope. The optimal pressure for injection is as low as possible. However, the exact pressure cannot be determined until the injection process begins.

“At what pressure am I going to inject the grout?” This question is not only common but also crucial on leak seal jobs, as it directly impacts the quality of your work. The answer, however, is not as straightforward as one might hope. The optimal pressure for injection is as low as possible. However, the exact pressure cannot be determined until the injection process begins.