A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

A general contractor working on new luxury apartment construction in Queens, NY reached out to a local leak seal specialist after discovering hairline cracks in the base joint of a fire protection storage tank. (A fire protection storage tank stores water for use in fire suppression systems.)

Powerful Polymer

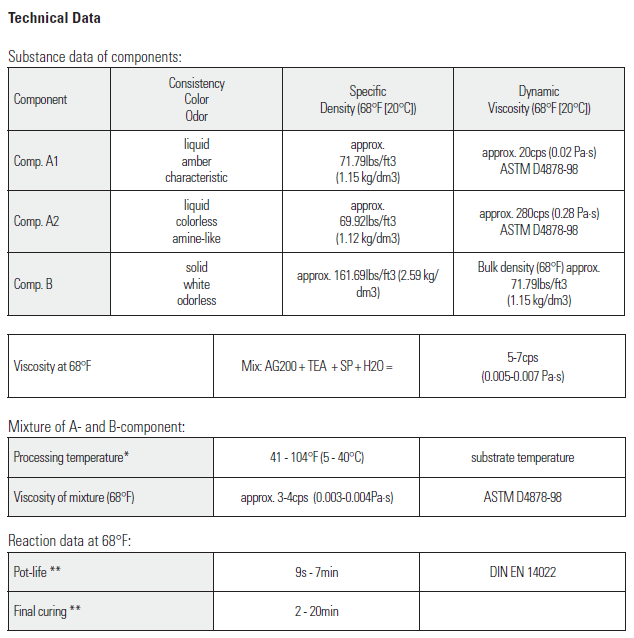

Cracks in concrete come in all widths and sizes. Some of the most difficult ones to inject are the hairline cracks. The thinnest flexible polyurethane grouts on the market are between 100cps - 200cps which makes it difficult if not impossible to get them to penetrate a hairline crack. Spetec AG200 is an acrylic-based grout and it is 18cps, or about 5-10 times thinner than the thinnest flexible polyurethane. Clearly, a thinner grout will penetrate cracks much more effectively. Spetec AG200 is almost as thin as water, but when it polymerizes it forms a flexible hydrophilic gel. This gel features 500% elongation, which may sound like overkill to some, but 500% movement in a hairline crack is not much. The ultra-low viscosity and field adjustable set time make Spetec AG200 ideal for thin and hairline cracks.

Painless Procedure

The crew followed the standard crack injection procedure:

- Identify crack locations.

- Estimate the amount of material needed.

- Prepare the surface of the crack.

- Drill injection holes at a 45-degree angle.

- Flush out injection holes with water to remove any debris.

- Insert injection ports on both sides of the crack.

- Inject water into each port.

- Start injection of material.

- Always grout twice.

- Add water again.

Spetec AG200 was successfully injected into cracks and the base joint of the firefighting water reserve tank.

Rapid Result

The defects in the tank were easily penetrated by Spetec AG200 and the job was a success. This allowed the general contractor to get back on schedule with the building construction.