What Causes Leaks in Concrete?

What Causes Leaks in Concrete?

Imperfect Construction

Concrete construction is by no means a perfect science. New construction often requires Leak Seal treatment follow-up work. If the initial construction isn’t properly sealed at the time of construction, leaks are bound to appear sooner rather than later.

Weather and Wear

Concrete naturally decays over time. Exposure to extremely hot temperatures and extremely cold temperatures can take their toll over time. Even structures located in mild climates will begin to decay purely due to the aging process.

Unstable Soil

Unstable soil can undermine the integrity of concrete structures and cause cracks to appear. Loose soil has four main causes: soil erosion, poor compaction, freeze/thaw cycles, and biological decay. If soil is the main culprit, additional stabilization and slab lifting treatments may be required in order to prevent further cracks from appearing.

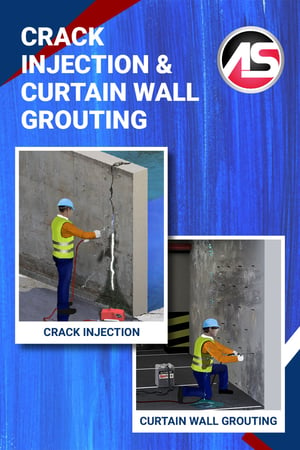

What is Curtain Grouting?

Curtain grouting is the process of injecting water-reactive resin behind the leaking wall in a grid pattern (from the negative side). The water on the other side mixes with the grout and cures to a solid mass covering the surface of the wall on the other side (positive side). In addition, you don’t have water pressure dislodging external “patches” over time, as can be the case with other methods.

Curtain grouting is often required when there are gushing leaks, multiple leaks in proximity, cracks cannot be identified, the walls are made of material that does not respond well to crack injection (such as masonry, stone, and CMU), or previous leak seal methods have failed.

The most well-known Alchemy-Spetec product for this application is Spetec PUR H100, a one-component, closed-cell, hydrophobic, water-reactive, solvent, and phthalate-free, low viscosity resin. If there are large voids involved, Spetec PUR HighFoamer (a similar product with a higher expansion rate) may be a more cost-effective option.

Want more information on curtain grouting?

Sealing Steam Leaks with Polyurethane

Sealing Steam Leaks with Polyurethane

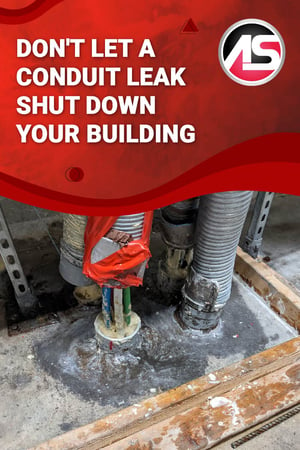

I was a Machinist Mate in the Navy and thus almost all of my training was mechanically focused. One class I had was Electrical Theory for Mechanics. The quick summation by the Senior Chief instructor for it was "Electricity is magic and when the smoke comes out the show is over." Being on a submarine it was deemed a good thing to keep water and electricity separate. My first time ever using polyurethane chemical grouts was on a group of sixteen conduits entering a below-grade mechanical room. While electricians may understand the "magic" of electricity they often fall short as waterproofers. Combined with the fact the numerous electrical cables coming through a conduit can be notoriously hard to waterproof and it is a recipe for leaks and electrical problems. In this post, I'll share step-by-step instructions, along with a couple of photos from a recent job one of our customers completed in a San Francisco condo complex.

I was a Machinist Mate in the Navy and thus almost all of my training was mechanically focused. One class I had was Electrical Theory for Mechanics. The quick summation by the Senior Chief instructor for it was "Electricity is magic and when the smoke comes out the show is over." Being on a submarine it was deemed a good thing to keep water and electricity separate. My first time ever using polyurethane chemical grouts was on a group of sixteen conduits entering a below-grade mechanical room. While electricians may understand the "magic" of electricity they often fall short as waterproofers. Combined with the fact the numerous electrical cables coming through a conduit can be notoriously hard to waterproof and it is a recipe for leaks and electrical problems. In this post, I'll share step-by-step instructions, along with a couple of photos from a recent job one of our customers completed in a San Francisco condo complex.

Sealing Leaks in Concrete with Polyurethane

Sealing Leaks in Concrete with Polyurethane

Alchemy-Spetec's

Alchemy-Spetec's

.jpg?width=1400&name=Banner%20-%20Saving%20a%20Luxury%20Penthouse%20Suite%20from%20Costly%20Water%20Damage%20(Just%20in%20Time).jpg)

A contractor in Atlanta was recently called in to seal off a rain-induced

A contractor in Atlanta was recently called in to seal off a rain-induced

What Causes Leaks in Concrete?

What Causes Leaks in Concrete?

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles, and decomposition.

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles, and decomposition.

Crack Injection Explained

Crack Injection Explained

Looking for polyurethane concrete repair product Tech Data Sheets, Safety Data Sheets, Application Procedures, Case Studies, Environmental Safety Info, or Specifications? All of these documents are available on one convenient page at Alchemy-Spetec's

Looking for polyurethane concrete repair product Tech Data Sheets, Safety Data Sheets, Application Procedures, Case Studies, Environmental Safety Info, or Specifications? All of these documents are available on one convenient page at Alchemy-Spetec's

A homeowner called

A homeowner called