Read through this list:

Read through this list:

- Manholes

- Catch basins

- Drop inlets

- Wet wells

- The Grand Canyon

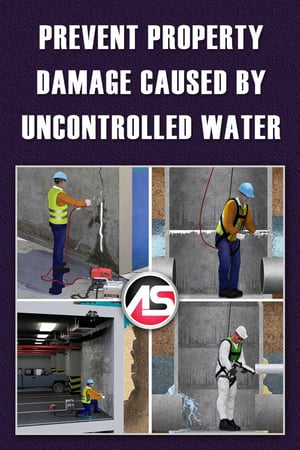

This is not a game of which one doesn't belong, as they all channel water and can cause erosion. The Grand Canyon is breathtaking. Likewise, washouts or sinkholes caused by leaking and neglected infrastructure are breathtaking - but in a completely different way. They're breathtaking in regard to the high costs of emergency repairs and the potential damage they cause.

This quote, from an article on KCCI.com, sums it up nicely...

“At first, crews resurfacing the pavement thought a large piece of machinery had fallen into a sinkhole 10 feet deep… It turns out an original clay storm sewer pipe had disconnected, leaking water for what appears to be a long time, eroding the earth around it.”

There is no downside to fixing these common infrastructure issues before they get out of control. Any repair costs are quickly offset by the reduction of sewer water requiring treatment. Who is not for lower sewer rates, a healthier environment, longer-lasting infrastructure, and fewer manmade washouts/sinkholes?

So why don’t we address infiltration more? It is as simple as the old adage "out of sight out of mind". Infiltration is a preventable and treatable sewage collection system problem. We have neglected our infrastructure for too long and we need to raise public awareness of the issue.

We at Alchemy-Spetec not only manufacture quality polyurethane chemical grouts for these types of repairs, but we also provide top-notch training and support for leak seal crews. Call 404-618-0438 and let us know how we can assist you in raising awareness about or repairing infiltration. We are all in this together.

The new and improved PolyShark 2.0 is here!

The new and improved PolyShark 2.0 is here!

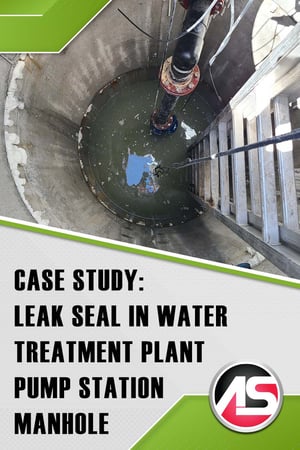

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

The Specialty Waterproofing with Chemical Grouts presentation explains and demonstrates how polyurethane chemical grout can be used to

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

The Geotechnical Applications for Polyurethane presentation explains and demonstrates how

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

Alchemy-Spetec grout labs are a great way to learn about industry-leading polyurethane leak seal products and applications. These are usually half-day events featuring...

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

One of the many joys of my job is going to all corners of North America and participating in unique projects. While I am a seasoned traveler, cement is not. Cement grout often requires heavy equipment. Shipping cement grout and related equipment can be expensive. While often not a concern for most projects, it is a driving factor for remote locations.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.

Loose, unstable slabs with voids underneath are often referred to as "rocking" slabs due to their movement when forklifts cross over them. Rocking slabs are a common problem in many warehouses. Left un-repaired, they can cause damage to equipment and injury to workers. Eventually, rocking slabs will require replacement if they are not repaired properly.