Municipalities across the country have widespread problems with water infiltration undermining the integrity of manholes, pipes, lift stations, water collection systems, etc. High-flow leaks in these structures add millions of dollars to maintenance and water treatment expenses every year.

Municipalities across the country have widespread problems with water infiltration undermining the integrity of manholes, pipes, lift stations, water collection systems, etc. High-flow leaks in these structures add millions of dollars to maintenance and water treatment expenses every year.

Limitless Leak Seal Market

We believe every qualified leak seal contractor should be prepared to take advantage of this type of job opportunity. Alchemy-Spetec offers environmentally-friendly leak seal resins for applications ranging from hairline cracks to gushing high-flow leaks. Our industry-leading technical support team (with decades of experience) assists infrastructure repair contractors on a wide variety of projects every day.

Spetec PUR H200 is a one-component, water-activated, hydrophobic, low viscosity, closed-cell polyurethane injection resin. When used with Gen ACC Fast, it is the fastest one-component Alchemy-Spetec grout. So it’s an ideal solution for quickly cutting off high-flow leaks.

Spetec PUR H200 Applications

The primary application for Spetect PUR H200 is cutting off high flow leaks quickly and effectively in manholes, pipes, lift stations, tunnels, mines, water collection systems, parking garages, and more. It's also great for curtain grouting projects. In addition, it can be used for filling water voids in the soil around all types of structures, cutting off underground water flows, and consolidating loose soil.

Spetec PUR H200 Advantages

Spetec PUR H200 is certified for contact with drinking water. The low viscosity allows for very effective soil permeation. It's water impermeable. The set time is adjustable – as fast as 20 seconds. It's also phthalate-free.

Your 3-Step Action Plan

Eliminate the risk to your client’s property and call our team of experts now to partner with the industry's leading technical support team. With our assistance, you can save your client’s property, save them money, and save their peace of mind.

- Start a conversation with one of our experts about your business and local market.

- We will work with you to create an action plan custom-tailored to your market’s needs.

- We will connect you with a local distributor and our technical service team to support you every step of the way.

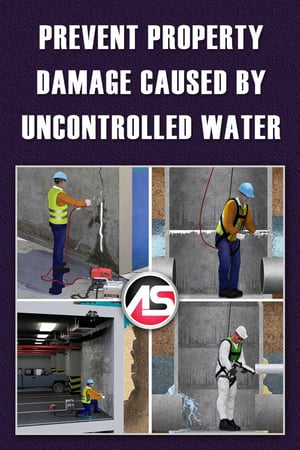

One of the greatest threats to our nation's infrastructure is unseen water eroding away its structural integrity. Water is relentless and all types of structures and sewer collection systems are at risk. If left unchecked, uncontrolled water will end up causing massive rehabilitation and repair bills. The market for repairing and controlling water infiltration is limitless.

One of the greatest threats to our nation's infrastructure is unseen water eroding away its structural integrity. Water is relentless and all types of structures and sewer collection systems are at risk. If left unchecked, uncontrolled water will end up causing massive rehabilitation and repair bills. The market for repairing and controlling water infiltration is limitless.

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

We often assume that our homes, roadways, and buildings are resting on solid ground - until that support starts to give way. The same natural element that carved out the Grand Canyon causes unstable soil, voids, and even sinkholes. Water is relentless and your property is at risk if soil damage is left unchecked. Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to the settling of a foundation or a roadway. Ignoring soil erosion underneath your property can lead to disaster.

Alchemy-Spetec offers a wide variety of online resources for current and aspiring infrastructure repair contractors. Let's take a look at what's available...

Alchemy-Spetec offers a wide variety of online resources for current and aspiring infrastructure repair contractors. Let's take a look at what's available...

Most property owners and managers don’t realize that the greatest threat to their slabs and structures hides underneath the surface of the ground. Water is relentless, and your property is at risk if it is left unchecked. Uncontrolled water can lead to soil erosion, voids, and sometimes even sinkholes. Neglecting these types of soil issues can end up costing significant money, time, and stress.

Most property owners and managers don’t realize that the greatest threat to their slabs and structures hides underneath the surface of the ground. Water is relentless, and your property is at risk if it is left unchecked. Uncontrolled water can lead to soil erosion, voids, and sometimes even sinkholes. Neglecting these types of soil issues can end up costing significant money, time, and stress.

Read through this list:

Read through this list:

The new and improved PolyShark 2.0 is here!

The new and improved PolyShark 2.0 is here!

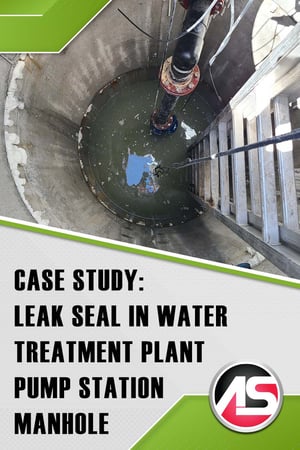

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

The Central Davis Sewer District (CDSD) is a publicly owned collection system and water treatment plant that serves three local cities in Northern Utah. With a new highway being constructed just outside their facility, a new pump station had to be installed on the premises. After installation of the new pump station, a large leak appeared in the manhole which caused it to fill up with about 10 feet of water. The CDSD contacted

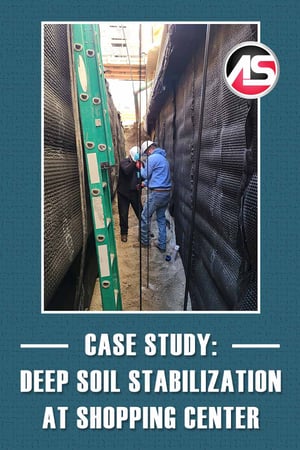

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.

City Creek Center is an up-scale shopping mall in downtown Salt Lake City. While under construction a five-foot-wide trench, located between two underground parking garages, was back-filled with pea gravel, and then a sidewalk was built on top of it. About ten years later the gravel began to settle enough to cause underground power lines to stretch and finally tear, knocking the power out for many of the local businesses. Engineers determined that the trench could be stabilized with the installation of polyurethane grout at depths of 30 feet below the surface.