The Great Plains of Canada stretch from Manitoba, across Saskatchewan, and on into Alberta. This predominantly agricultural region is the breadbasket of our neighbor to the North. Small towns and villages are scattered across these thousands of square miles, serving as the small population bases for the farming communities. These rural municipalities are faced with unique challenges when it comes to managing their water systems, roadways, and other infrastructure. For example, if there is a road that needs a small amount of paving or some concrete that needs to be poured, there may only be one time per year when the mobile batch plants comes through town. Combine this with some bitter cold, a very limited budget, and long distances to industrial centers, and you can see how it is hard on the small municipalities. Small issues are major, and major issues can be catastrophic.

The Great Plains of Canada stretch from Manitoba, across Saskatchewan, and on into Alberta. This predominantly agricultural region is the breadbasket of our neighbor to the North. Small towns and villages are scattered across these thousands of square miles, serving as the small population bases for the farming communities. These rural municipalities are faced with unique challenges when it comes to managing their water systems, roadways, and other infrastructure. For example, if there is a road that needs a small amount of paving or some concrete that needs to be poured, there may only be one time per year when the mobile batch plants comes through town. Combine this with some bitter cold, a very limited budget, and long distances to industrial centers, and you can see how it is hard on the small municipalities. Small issues are major, and major issues can be catastrophic.

In central Saskatchewan we have a contractor, JACC Structures, that we have been working with going on our third year now. The owner, Randy Serhan, purchased a slab lifting poly rig from our company and we helped him on his first big job, lifting all of the slabs in a cement plant that was being converted to a seed sorting facility. (Click here for the case study on that job.) Since that successful project, we have increased Randy and his crew's training to include crack injection, curtain wall grouting, and permeation grouting for soil stabilization. With these skills he has found a lot of opportunities to stop leaks and stabilize soil for mines, agricultural facilities, and municipalities. Many times a hero in his 22 years working as a Royal Canadian Mounted Police officer, he is now seen in that same light as he saves small communities thousands of dollars saving roads and infrastructure that otherwise might fail.

In central Saskatchewan we have a contractor, JACC Structures, that we have been working with going on our third year now. The owner, Randy Serhan, purchased a slab lifting poly rig from our company and we helped him on his first big job, lifting all of the slabs in a cement plant that was being converted to a seed sorting facility. (Click here for the case study on that job.) Since that successful project, we have increased Randy and his crew's training to include crack injection, curtain wall grouting, and permeation grouting for soil stabilization. With these skills he has found a lot of opportunities to stop leaks and stabilize soil for mines, agricultural facilities, and municipalities. Many times a hero in his 22 years working as a Royal Canadian Mounted Police officer, he is now seen in that same light as he saves small communities thousands of dollars saving roads and infrastructure that otherwise might fail.

Take the small community of Star City, Saskatchewan as a recent example. They had a corrugated metal culvert that passed under a gravel road for about 60 feet. Most of the roads there are gravel and this was one of the major routes used by farm combines and tractors. The last several years Saskatchewan has been plagued by high water tables, often making some farmland unusable. The culvert in Star City was subject to a good amount of water flow and over time, the water actually washed out the soils around the inlet of the pipe. This progressed until there were actual streams of water flowing beside and beneath the pipe, rather than through it. This is not unusual and in a lot of cases it is undetected; the erosion of the soil eventually washing out to the point that the the overburden collapses. In this case the road would have caved in unless it was treated.

For anyone who has ever installed large culverts made of plastic or corrugated steel, you know that it is the back fill around the pipe that provides a lot of the strength. Trying to pack soils or rock underneath the lower areas of a pipe is difficult at best and that's often an area of weakness. In this case the soils washed out and something needed to be done. Star City and JACC knew of each other through tradeshows like the SWA conference in Saskatoon. The municipality reached out to Randy and asked him to come take a look at the problem. "You betcha" was the standard Canadian reply when they asked if he had a solution.

As I mentioned, these types of problems with erosion around culverts are not unusual. The town was already looking at a $65,000 outlay to have the road and culvert dug up and replaced, in addition to the $25,000 cost of the culvert itself. Not to mention the downtime and inconvenience of having to go miles out of the way to get past the road closure. Working from the inlet of the pipe and on through it, JACC injected two rows of structural AP Lift 475 through the wall of the pipe, to provide a bedding for the pipe and to fill up the erosion voids created by the water flow. One row was at approximately the 5 o'clock position in the pipe and the other row mirrored at the 7 o'clock position. This work was all completed without any excavation or road closure. The end result was a total success with the water flow cut off, the pipe bedding stabilized and strengthened, and the voids filled. It was completed in less than a day and at a cost to the city below 5 figures.

Want more information on Alchemy-Spetec products?

As Andy Powell states in his post:

As Andy Powell states in his post:

The Great Plains of Canada stretch from Manitoba, across Saskatchewan, and on into Alberta. This predominantly agricultural region is the breadbasket of our neighbor to the North. Small towns and villages are scattered across these thousands of square miles, serving as the small population bases for the farming communities. These rural municipalities are faced with unique challenges when it comes to managing their water systems, roadways, and other infrastructure. For example, if there is a road that needs a small amount of paving or some concrete that needs to be poured, there may only be one time per year when the mobile batch plants comes through town. Combine this with some bitter cold, a very limited budget, and long distances to industrial centers, and you can see how it is hard on the small municipalities. Small issues are major, and major issues can be catastrophic.

The Great Plains of Canada stretch from Manitoba, across Saskatchewan, and on into Alberta. This predominantly agricultural region is the breadbasket of our neighbor to the North. Small towns and villages are scattered across these thousands of square miles, serving as the small population bases for the farming communities. These rural municipalities are faced with unique challenges when it comes to managing their water systems, roadways, and other infrastructure. For example, if there is a road that needs a small amount of paving or some concrete that needs to be poured, there may only be one time per year when the mobile batch plants comes through town. Combine this with some bitter cold, a very limited budget, and long distances to industrial centers, and you can see how it is hard on the small municipalities. Small issues are major, and major issues can be catastrophic. In central Saskatchewan we have a contractor, JACC Structures, that we have been working with going on our third year now. The owner, Randy Serhan, purchased a slab lifting poly rig from our company and we helped him on his first big job, lifting all of the slabs in a cement plant that was being converted to a seed sorting facility. (

In central Saskatchewan we have a contractor, JACC Structures, that we have been working with going on our third year now. The owner, Randy Serhan, purchased a slab lifting poly rig from our company and we helped him on his first big job, lifting all of the slabs in a cement plant that was being converted to a seed sorting facility. (

.png?width=320&name=Curtain%20Wall%20Grouting-blog%20(3).png) Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

Curtain wall grouting is a leak seal method that is often required when cracks cannot be identified, when walls are made of material that does not respond well to crack injection (such as masonry, stone and CMU), and when previous leak seal methods have failed.

.png?width=320&name=Residential%20Seawall%20Repair-blog%20(1).png) But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

.png?width=396&name=tools-blog%20(4).png) But first you’ve got to understand one thing; you can’t bring a knife to a gunfight. Expert contractors have to know what is going on at all times. In the picture at the top of this post, you can see a slab that I probably would have not attempted to repair. However, with several tools to help monitor the different pieces of this puzzle, this contractor was able to put it back together again. They say information is power and I am a firm believer in that, especially when it comes to taming jacked up concrete slabs. In the picture you can see three different slabs. Our customer Morgan Helms of Helms Polyfoam (Jackson, MS) is using a ZipLevel, a machinist’s dial indicator, and a putty knife to monitor what each of the slabs is doing.

But first you’ve got to understand one thing; you can’t bring a knife to a gunfight. Expert contractors have to know what is going on at all times. In the picture at the top of this post, you can see a slab that I probably would have not attempted to repair. However, with several tools to help monitor the different pieces of this puzzle, this contractor was able to put it back together again. They say information is power and I am a firm believer in that, especially when it comes to taming jacked up concrete slabs. In the picture you can see three different slabs. Our customer Morgan Helms of Helms Polyfoam (Jackson, MS) is using a ZipLevel, a machinist’s dial indicator, and a putty knife to monitor what each of the slabs is doing. The dial indicator tells him which slab is moving. In the picture, the base of the dial indicator is on the slab that Morgan is injecting under while the dial point is on the slab he doesn’t want to move. It doesn’t really matter how you configure it as long as you understand what the needle movement means. A needle on a machinist dial indicator moves in .001” increments. If the needle on this dial indicator is rising, that would mean the wrong slab is lifting and he knows to stop. If the needle is falling then the slab he is injecting under is lifting, and that’s what he wants.

The dial indicator tells him which slab is moving. In the picture, the base of the dial indicator is on the slab that Morgan is injecting under while the dial point is on the slab he doesn’t want to move. It doesn’t really matter how you configure it as long as you understand what the needle movement means. A needle on a machinist dial indicator moves in .001” increments. If the needle on this dial indicator is rising, that would mean the wrong slab is lifting and he knows to stop. If the needle is falling then the slab he is injecting under is lifting, and that’s what he wants. So what if both slabs are moving equally? In that case the dial indicator would remain stable or fluctuate slightly in both directions. This is where a ZipLevel or a laser transit would come in handy. Morgan has his ZipLevel indicator box (in yellow) on the slab he doesn’t want to move. It will let him know if the slab he doesn’t want to move is lifting so he can stop and re-evaluate what to do next.

So what if both slabs are moving equally? In that case the dial indicator would remain stable or fluctuate slightly in both directions. This is where a ZipLevel or a laser transit would come in handy. Morgan has his ZipLevel indicator box (in yellow) on the slab he doesn’t want to move. It will let him know if the slab he doesn’t want to move is lifting so he can stop and re-evaluate what to do next. One of my favorite tools is the metal putty knife. Slabs often move in increments so small that you can’t detect them visually. If you wedge a putty knife into a crack between two slabs, you will see it wiggle when there’s slight movement. So the putty knife in the picture is on the third section of slab and letting Morgan Helms know what is going on with that piece.

One of my favorite tools is the metal putty knife. Slabs often move in increments so small that you can’t detect them visually. If you wedge a putty knife into a crack between two slabs, you will see it wiggle when there’s slight movement. So the putty knife in the picture is on the third section of slab and letting Morgan Helms know what is going on with that piece.

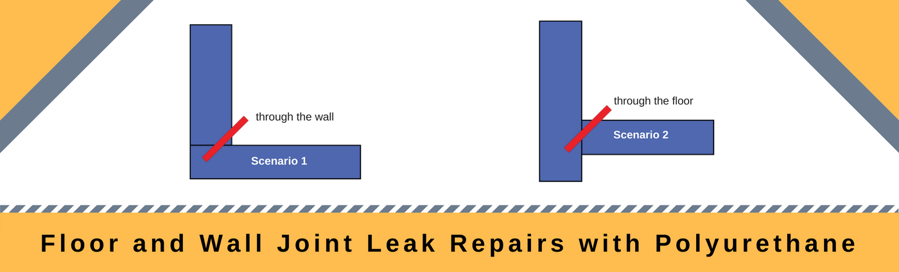

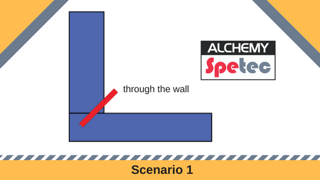

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.

In this scenario the floor has been poured first before a wall is made to confine a space. To fix leaks that occur in this type of joint, a hole is drilled at the bottom of the wall. This is usually about 6-8 inches above the floor and at a 45 degree angle. Once drilled, soaked oakum is then placed in the hole. Once cured, the oakum serves as a gasket and initial leak seal. Polyurethane grout is then pumped into the hole for a deeper seal, while the oakum gasket prevents it from spilling back out.-1.png?width=320&name=floor%20wall-%20blog%20(1)-1.png) In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.

In this scenario the wall has been poured first before the floor. The hole is drilled on the floor about 6-8 inches from the wall and at a 45 degree angle. Soaked oakum is placed into the hole to create an initial seal and gasket. Polyurethane grout then injected behind it for a thorough leak seal solution.