Today I finally heard from a customer in the Naples Florida area. I have been trying to reach these guys since hurricane Irma rolled through, so it was a relief to finally talk to them. They are still 3 weeks away from getting power. Thank goodness they have a slab lifting rig with a big generator to get some power and AC going.

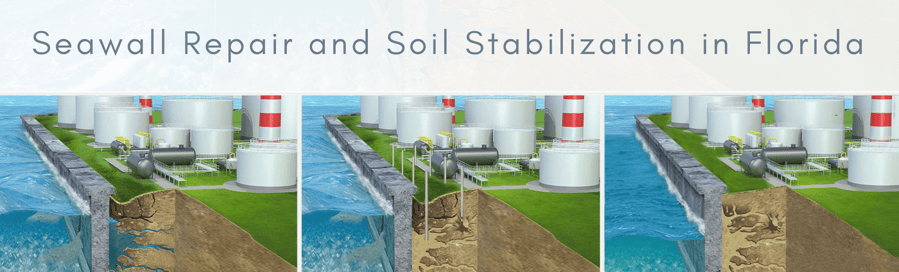

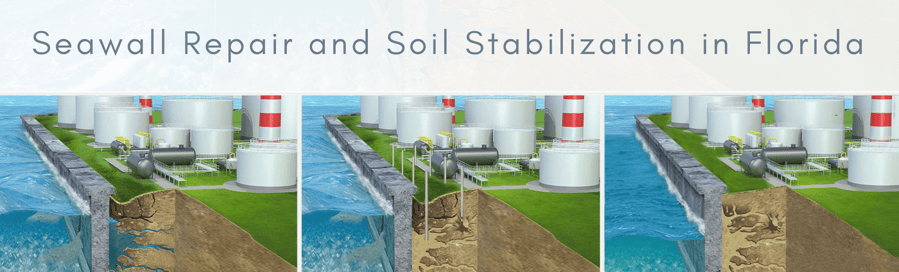

All across the gulf coast and east coast, seawalls and other structures near the water have been put under immense stress. Severe scouring, sinkholes, and seawall failures are being reported. The damage is staggering.

One hurricane-related phenomenon that occurred on Florida's west coast was a suction that drained the water from harbors and bays. You may have seeen the videos on YouTube. Unfortunately, that sucking action pulled with it tons of sandy soil from behind seawalls and bulkheads. In many cases the seawall toes have completely blown out. The amount of property in danger due to further erosion and exposure to the sea is sobering.

There is help available. Alchemy-Spetec and our network of certified contractors are experienced at stopping soil loss, fixing sinkholes, and stabilizing bulkheads and repairing seawalls. In cases where the entire seawall was destroyed, soil stabilization may be the only line of defense against a growing loose soil zone threatening to consume the property your business or home is built on.

.png?width=320&name=Seawall%20Repair-blog%20(1).png) The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product, AP Fill 700, has a controlled reaction time that gives the experts the control to make the material do what they want it to. Whether it’s binding soil or filling voids and seawall breaches; it fits the bill.

The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product, AP Fill 700, has a controlled reaction time that gives the experts the control to make the material do what they want it to. Whether it’s binding soil or filling voids and seawall breaches; it fits the bill.

AP Fill 700 is drinking water contact approved and phthalate free. Don’t forget to inquire about that with your contractor. Some competitor products contain phthalates and those are marine toxins. Alchemy-Spetec has your back when it comes to the environment.

Protect your property, stop loss of soil and the formation of dangerous sinkholes, and trust our certified contractors that use Alchemy-Spetec soil stabilizing and seawall protecting polyurethanes.

Call 404-618-0438 to get the help you need.

Want more information on polyurethane seawall repair?

It looked like the lady was going to be okay but the point is that this was probably avoidable. When I ran to her side I could see the sidewalk tripping hazard that had caused her to fall. Combined with the dim lighting it was a case of dual premises liability. I give talks to groups like

It looked like the lady was going to be okay but the point is that this was probably avoidable. When I ran to her side I could see the sidewalk tripping hazard that had caused her to fall. Combined with the dim lighting it was a case of dual premises liability. I give talks to groups like

-2.png?width=560&height=315&name=re-circulating%20the%20material-%20blog%20(1)-2.png) Step 2:

Step 2: Step 3:

Step 3:.png?width=899&height=273&name=concrete%20crack-banner%20(1).png)

I recently consulted with

I recently consulted with

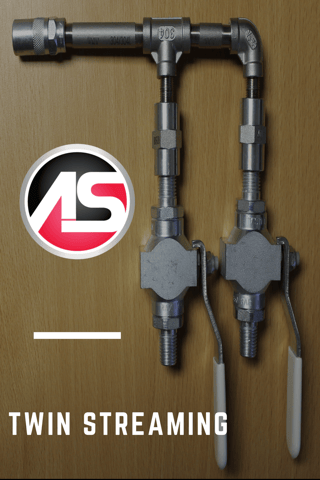

.png?width=899&height=273&name=Twin%20Streaming%20(2).png)

Advantages:

Advantages:

-1.png?width=899&height=273&name=Waterstop-banner%20(1)-1.png)

.png?width=471&name=Waterstop-blog%20(6).png) This is a caulk designed to swell and/or expand in the presence of water. It is safe for marine environments and can be applied under water.

This is a caulk designed to swell and/or expand in the presence of water. It is safe for marine environments and can be applied under water. .png?width=471&name=Waterstop-blog%20(5).png) The

The .png?width=471&name=Waterstop-blog%20(4).png) Spetec SST500

Spetec SST500

.png?width=899&height=273&name=Distributor%20Profile%20Series-%20(2).png)

.png?width=320&name=Distributor%20Profile%20Series-%20(1).png)

.png?width=320&name=Seawall%20Repair-blog%20(1).png) The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product,

The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product,