The Alchemy-Spetec structural repair product line consists of products for patching, joint filling, spall repair, anchoring, and bonding.

The Alchemy-Spetec structural repair product line consists of products for patching, joint filling, spall repair, anchoring, and bonding.

Cementitious Patching Material

AP Gel Patch is a polymer modified, cementitious patching material for structural repair of deteriorated concrete. For use on above or below grade structures. It can be used on vertical or overhead structures. Read more...

Poyurea Joint Filler

AP Joint Fill 800 is a two-component hybrid polyurea joint filler with fast reaction allowing for shave time in as little as 5 minutes. The fast reaction allows for minimal down time and facilities to be in operation quickly. Read more...

Polyurethane Spall Repair

AP Fast Repair 850 is a zero VOC, two-component polyurethane system. The high-quality thermoset is designed for fast repair of concrete (spalls, cracks, etc.). Its low viscosity allows for maximum penetration into cracks and porous concrete. This product can be mixed with up to equal parts oven dry silica sand to increase product yield and compressive strength. Read more...

Non-Sag Epoxy for Structural Anchoring/Bonding

AP NS950 Epoxy is a two component, non-sag structural epoxy designed to offer exceptional mechanical strength in anchoring/bonding applications. Due to its high bond strength to concrete, it is ideal to use for anchoring threaded rod or rebar dowels. The consistency of AP NS950 EPOXY is good for capping for crack injection or general surface repairs. AP NS950 EPOXY is 100% solids, VOC free and Butyl Glycidyl Ether (BGE)* free. Read more...

Low-Viscosity Expoxy for Structural Bonding of Cracks

Epicol INJ LV is a low-viscosity epoxy resin for structural bonding of cracks and micro cracks in dry or wet concrete. Can be used as glue for bonding and anchoring. Read more...

AS Pump Flush is a high-performance pump flush that is friendly to the environment and does an excellent job flushing out injection pumps.

AS Pump Flush is a high-performance pump flush that is friendly to the environment and does an excellent job flushing out injection pumps.

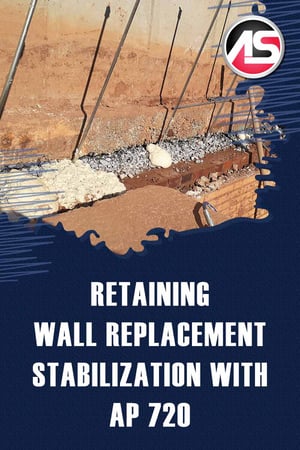

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

When an old brick retaining wall in downtown Greenville collapsed and crushed three cars,

As the weather gets colder, contractors in some regions will need to prepare their

As the weather gets colder, contractors in some regions will need to prepare their

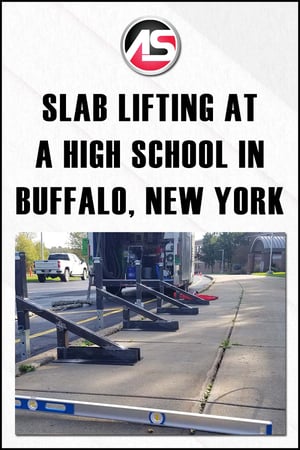

A general contractor working for a school district in Buffalo, New York was asked to lift and level around 550 feet of sidewalk slabs at a local high school. The general contractor called in slab lifting specialists

A general contractor working for a school district in Buffalo, New York was asked to lift and level around 550 feet of sidewalk slabs at a local high school. The general contractor called in slab lifting specialists

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.

On October 26th - 28th, Contractors across North America traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

On October 26th - 28th, Contractors across North America traveled to Alchemy-Spetec HQ in Tucker, GA for a thorough education in Slab Lifting, Soil Stabilization, the Deep Lift® process, equipment, and applications. They received hands-on training from a technical staff with decades of on-the-job experience.

Alchemy-Spetec's

Alchemy-Spetec's

As the weather gets colder, contractors in some regions will need to prepare their slab lifting rigs for storage during the off-season. We're providing step-by-step instructions for that procedure in this article.

As the weather gets colder, contractors in some regions will need to prepare their slab lifting rigs for storage during the off-season. We're providing step-by-step instructions for that procedure in this article.