Crack Injection Explained

Crack Injection Explained

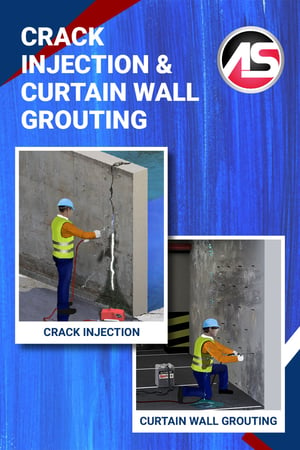

Crack injection has many advantages over other methods. For example, if you’re sealing a leak in a water tank, you can inject from the outside of the tank. So the tank can remain in service while you repair it. Having to dry a crack, like you do with epoxy resin, is not needed as this material reacts with water. The material also remains flexible at all times.

Crack injections can be applied in both vertical cracks and in horizontal cracks. With vertical cracks, it is imperative to start at the bottom of the crack and work your way up the crack until it is filled. This forces the material up and through the crack and will simultaneously push the water up and out as well. With horizontal cracks, injection can be started at either the left or right end.

Read more from Charlie Lerman's article Crack Injection Explained.

Curtain Wall Grouting Explained

Curtain wall injection is the process of drilling holes through a structure in a diamond pattern, then injecting the grout into soil on the other side. This procedure creates a curtain wall made of a resin/soil mixture that prevents water from getting back into the structure. It is often required if there are multiple cracks or leaks in a wall. Filling each individual crack may cause you to waste time following the water from crack to crack. Curtain wall grouting allows you to stop multiple leaks at one time and protects the structure on a long term basis.

This procedure was first performed in 1960 on a sewer manhole with a multiple leak problem. As described above, chemical grout was injected through to the outside of the manhole. This created a “positive side seal” (on the side the water was coming from), blocking water from penetrating the joints of the structure.

Read more from Charlie Lerman's article Curtain Wall Grouting Explained.