This article is an excerpt from Episode 4 of The Injection Connection, featuring Adam Tracy of A-1 Foundation Crack Repair. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

This article is an excerpt from Episode 4 of The Injection Connection, featuring Adam Tracy of A-1 Foundation Crack Repair. The Injection Connection is hosted by Jim Spiegel: Vice President of Alchemy-Spetec and Board Member at the International Concrete Repair Institute. (If you'd rather listen, an audio version of this exchange is posted at the bottom of the article.)

Jim: Where do we find talent? That’s a big thing in our world especially being so niche of an application. How do you find talent? One of the things that we like to look at is, getting somebody with an engineering mind, such as yourself - engineering or architectural mind that just knows buildings and knows the X’s and O’s of the construction world and just get them on site, just to learn. We think that could be the one-two punch to really get good, competent people out there. You’re a perfect example of it. You come in with a very high level of understanding of the construction world and building in general and then couple that with some field training and you’re pretty lethal as far as your effectiveness in the field.

To that point, how long do you think it takes? Say somebody coming out of college: I have a bachelor’s in engineering, maybe I don’t want to work in an engineering firm, maybe I want to get into the sales side with the manufacturer building products. How long do you think it takes in field time with chemical grouting until you’re up and running and you really know the nuances of a lot of what happens out there?

Adam: That’s a tough question. I’ve used myself as a little bit of an example because while I’d been around it for a while because I had gone my own path for a period of time right out of school, it was kind of just there and didn’t really know much about it. Doing it every day, it was a good with my educational background being an engineer in the civil engineering space. Knowing building and construction, it took me a good two, three months of every day (hands-on application to really understand the limitations, the successes, how it works, why it works, which product is going to be most successful, in which application) until I was comfortable being able to see the solution before I even put a drill to a wall. The fortunate thing is that I was able to rely on years of construction experience and being in these green builds whereas somebody who might be right out of school has never been on a site, has never thrown on the hardhat and the vest and walked around. So there’s a whole learning curve to that as well. But again, the field experience I think is critical in any industry. Especially as you get into more and more isolated niche industries, your opportunity to learn is few and far between on a study level. The field experience becomes your classroom.

When we bring people on, talking about finding good people, if we find somebody who has any experience in injection grouting, it’s a diamond, it’s a needle in a haystack so to speak. There’s a significant training curve on our end to bring talented people who have this construction experience to a level of being able to be proficient in the trade.

It’s a tough thing because everyone’s individual but the more time in the field, I think, is critical because, again, if you happened to be taught it in some educational level, it was a leap on the radar and it was quickly moved past as part of envelope education study whereas the actual time in the field really becomes your classroom, like I said.

Jim: Absolutely. It’s your point though or kind of to the point, two or three months was effectively your gut, visceral reaction there to time in the field. Compared to some other industries, that’s not all that long.

Adam: No but that was an everyday obligation.

Jim: Exactly. You take like a manufacturer rep for instance who might be on site once a month for a few hours to add that time up to be two months, constant trained would take years to become that well-versed.

Adam: In like anything. I’ve lived in that sales role as a manufacturer sales rep and while you may know the spec sheet of your product inside and out, that doesn’t tell you the whole story of the product that you’re going to use. It’s when it’s applied in the field whether it’s a pump or a truck or a crane or chemical grouting, it’s the performance in the real world beyond the spec sheet that tells you or completes a picture of your education on the product.

For those who are on the manufacturing side, the time in that field, actually doing the work I think is one of the most critical parts of it.

Jim: For sure. We liken it to a mechanic who can listen to an engine and give you a pretty good of what he’s up against. Very similar in the field, Charlie, who I mentioned, I think he’s been in the field services role for 15, 16 years as well and he can tell you what’s happening by the way the hose is jumping for instance on each stroke, and the sound of the stroke for instance. There’s a lot of that mechanic level field support that just isn’t that readily available in the chemical grouting world. We put Charlie in the field services director role because, and this is not intended to go into a sales pitch but just to your point that a lot of manufacturers are kind of shying away from the field support where you have to be out there seeing so many customers and making so many calls and it’s like a telemarketing solution sometimes for an industry that is so critical for accuracy in the field.

I agree with you completely. We actually tell our guys, you said you had experience on the sales side of it from manufacturer, and we tell all of our guys and girls – get in the field and spend time with the contractors. I still go out in the field. I was just on a job a couple of Fridays ago, we were doing polyacrylate gel injection. I was on the gun and I was saying to the technicians – you guys tell me, instruct me a little bit what you see out here because a couple of people who were out there had significant experience.

To your exact point, manufacturers can read spec sheets and tell you little nuances of performance from TDS but until you know what the gun feels like, the guys in the field are still probably head and shoulders above you.

Adam: Yeah, for sure. And it’s always tough to be in that role where you’re supposed to be the expert and asking for help. I’ve been in those situations, it’s always uncomfortable as being on the manufacturer side to say, "okay, what would you guys do here?"...you know, being the guy with 30 years of experience.

Want more information on leak seal methodology?

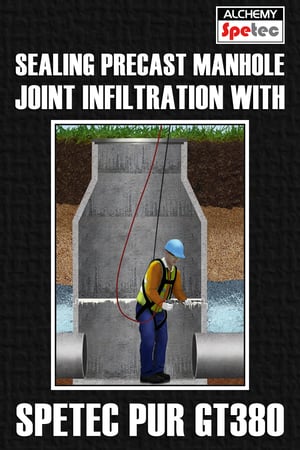

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

In this post, we’re profiling

In this post, we’re profiling

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

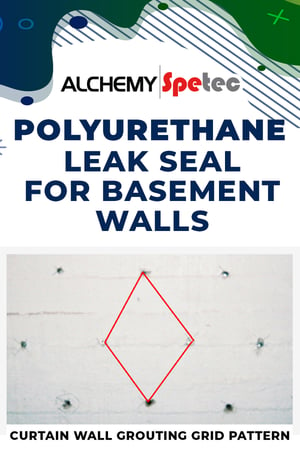

Embedded below is a crack and curtain grouting video demo I recently recorded. For those not familiar with me, my name is Charlie Lerman. I'm the Director of Technical Services for the Leak Seal Division at Alchemy-Spetec (and I'm also known as the Grout Geek). I have been involved in a wide variety of grouting jobs from dams to tunneling, municipal to sewer system work, residential, commercial, and industrial.

Embedded below is a crack and curtain grouting video demo I recently recorded. For those not familiar with me, my name is Charlie Lerman. I'm the Director of Technical Services for the Leak Seal Division at Alchemy-Spetec (and I'm also known as the Grout Geek). I have been involved in a wide variety of grouting jobs from dams to tunneling, municipal to sewer system work, residential, commercial, and industrial.

Polyurethane – Quality and Selection

Polyurethane – Quality and Selection

I'd like to share a case study from a job that I recently consulted on with one of our contractor customers.

I'd like to share a case study from a job that I recently consulted on with one of our contractor customers.

Today’s guest blogger is John Ziebell, an independent representative of Alchemy-Spetec. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI).

Today’s guest blogger is John Ziebell, an independent representative of Alchemy-Spetec. Formerly the Vice President of Operations for Deneef Construction Chemicals, Inc., John has 36 years of experience in the chemical grout industry and is currently a member of the International Concrete Repair Institute (ICRI).