Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Newcomers to urethane grouts often cut their teeth on these two terms, but the industry in general struggles with the understanding of what they are, and when to use hydrophobic vs. hydrophilic polyurethane grouts. So, I will cover the differences and then point out what I feel is a much more important conversation about polyurethane chemical grouts.

Hydrophobic

- Cured States: Rigid, Semi-Rigid, Flexible Foam

- Reaction: Requires Water

- Requires Accelerator: Yes

- Elongation: None to 100%

- Wet/Dry Cycling: Unaffected

- Adhesive Bond: Good

- Pumped and Handles as: Single Component

Hydrophilic

- Cured States: Flexible Foam or Gel

- Reaction: Requires Water

- Requires Accelerator: No

- Elongation: None to 300%

- Wet/Dry Cycling: Can Dry Out

- Adhesive Bond: Superior

- Pumped and Handles as: Single Component

Somehow, the industry has erroneously assumed hydrophobic means: "fears water and pushes it away". While at the same time assuming hydrophilic means: "loves water and draws it in". There are some truths in these statements but they are only the core and are wrapped in misconceptions.

Misconception One: Water Loving and Water Fearing

Both grouts require water to activate and yes, the hydrophilic grout can incorporate more of the water into its cell structure, but both grouts will push water away when they have reacted with enough water to polymerize.

Misconception Two: Hydrophilic Grouts Dry Out and Shrink Without Water

A more accurate statement would be that cured hydrophilic urethane grouts can dry out and shrink in an arid environment. Concrete normally has a relative humidity of around 60% which will keep a hydrophilic foam hydrated. Soils can vary in their relative humidity but most often have enough moisture not only to keep a hydrophilic grout hydrated but also enough to polymerize a hydrophobic grout without the need for added water.

Misconception Three: Hydrophilic Grouts Have Better Adhesion

It is 100% true hydrophilic grouts have better adhesion in ASTM lab testing, and I did just list them as having superior adhesion. But, in my twenty-plus years in construction, I have never seen a grout job performed under laboratory conditions. Adhesion requires a clean surface for bonding. During crack injection, surface prep is a water flush in a crack we cannot see. So clearly it would be silly to believe we have a pristine surface inside the crack to adhere to. So yes, in a lab, hydrophilic grouts adhere to concrete better than hydrophobic grouts. In situ, both have a weak adhesive bond and both rely on their compressive and mechanical bonds much more than on an adhesive bond.

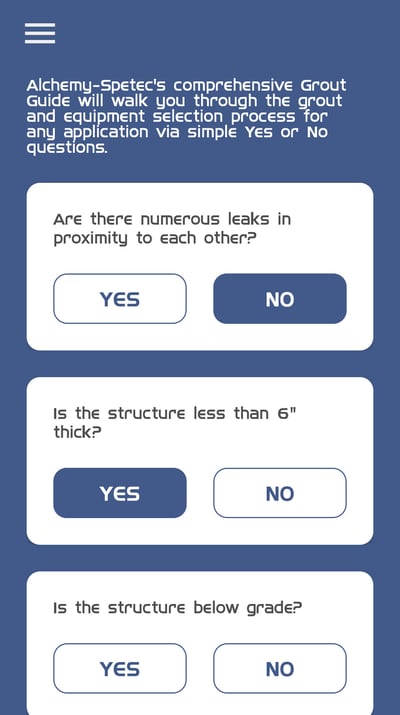

So, it's important to understand there is much more to grout selection than just hydrophilic and hydrophobic. I would estimate around 60% of chemical grouters only chemical grout a few times year. This can make product and methodology selection very difficult. That is why I am here with the Alchemy-Spetec team to help navigate you through these critical nuances. Call us at 404-618-0438 for technical assistance!

Municipalities across North America have widespread problems with Inflow and infiltration (I&I). Inflow is in reference to stormwater that invades sewer systems. Infiltration is in reference to groundwater infiltrating manholes, lift stations, pipes, and other sanitary system components. While there are a few solutions on the market for mitigating inflow, this article is primarily focused on mitigating infiltration with polyurethane grout.

Municipalities across North America have widespread problems with Inflow and infiltration (I&I). Inflow is in reference to stormwater that invades sewer systems. Infiltration is in reference to groundwater infiltrating manholes, lift stations, pipes, and other sanitary system components. While there are a few solutions on the market for mitigating inflow, this article is primarily focused on mitigating infiltration with polyurethane grout.

One of the most common questions I get about leak seal grout is along the lines of "Can I do this or that? Will it work?". I get this type of question regularly because every job is very unique and there is no one precise grouting procedure that fits everything. Let me introduce you to a term I love to use: exploratory grouting. This is the phase in which you are trying various methods until you find one that works for your particular application. While this just sounds like guesswork, it is very far from that.

One of the most common questions I get about leak seal grout is along the lines of "Can I do this or that? Will it work?". I get this type of question regularly because every job is very unique and there is no one precise grouting procedure that fits everything. Let me introduce you to a term I love to use: exploratory grouting. This is the phase in which you are trying various methods until you find one that works for your particular application. While this just sounds like guesswork, it is very far from that.

Do you know that leak that returns every year no matter how much hydraulic cement you put on it? Why not make this next time the last time you have to mess with it? Polyurethane grouts have some unique properties that allow them to do things concrete cannot. One of the most glaring is its flexibility.

Do you know that leak that returns every year no matter how much hydraulic cement you put on it? Why not make this next time the last time you have to mess with it? Polyurethane grouts have some unique properties that allow them to do things concrete cannot. One of the most glaring is its flexibility.

Polyurethane foam was first discovered in 1937 by Dr. Otto Bayer who lived in Leverkusen, Germany. Bayer was a German chemist and was the head of the research group that discovered this new material. His fundamental idea of combining small volumes of chemical substances together to react into a dry foam material was viewed to be an impossibility. But after many trials and difficulties, Bayer eventually succeeded in synthesizing the first polyurethane foam.

Polyurethane foam was first discovered in 1937 by Dr. Otto Bayer who lived in Leverkusen, Germany. Bayer was a German chemist and was the head of the research group that discovered this new material. His fundamental idea of combining small volumes of chemical substances together to react into a dry foam material was viewed to be an impossibility. But after many trials and difficulties, Bayer eventually succeeded in synthesizing the first polyurethane foam.

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

It's that time of year again. As temperatures drop, take a moment to review this previously posted article packed with cold-weather tips.

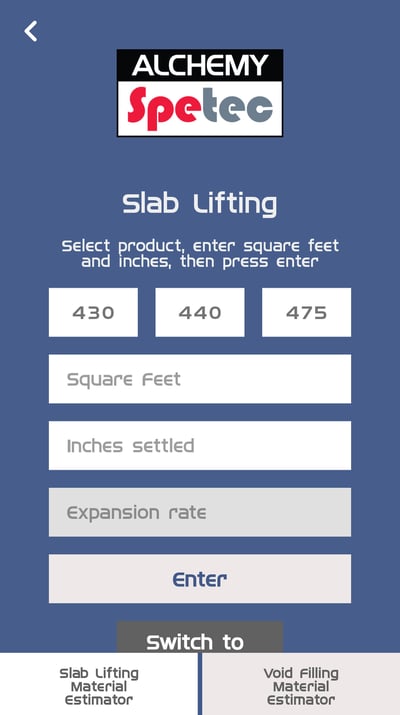

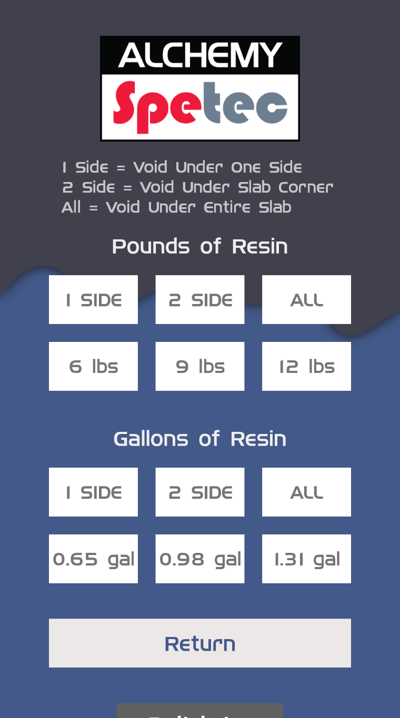

The warehouse slab/floor repair market can be a goldmine for contractors. Most major metro areas contain endless square miles of warehouse space. That's why we've posted a good number of warehouse floor and slab repair articles on this blog over the years. In this post, we'll introduce and link to the best Alchemy-Spetec warehouse slab repair articles.

The warehouse slab/floor repair market can be a goldmine for contractors. Most major metro areas contain endless square miles of warehouse space. That's why we've posted a good number of warehouse floor and slab repair articles on this blog over the years. In this post, we'll introduce and link to the best Alchemy-Spetec warehouse slab repair articles.

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.

Charlie Lerman, a.k.a. "The Grout Geek", is Alchemy-Spetec's Director of Technical Services - Leak Seal Division. The importance of waterproofing became critical to him while serving on nuclear submarines in the U.S. Navy. With decades of experience in construction and leak seal, Charlie commands unparalleled expertise in grouting techniques and water mitigation.