Sealing Steam Leaks with Polyurethane

Sealing Steam Leaks with Polyurethane

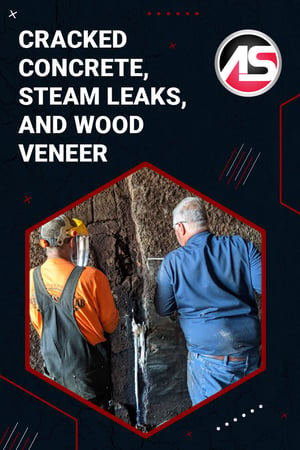

One of the most high-tech veneer manufacturing companies in the United States chose Alchemy-Spetec to train their maintenance techs to stop a steam leak in their facility. You heard that right. Not liquid water, but steam leaks! Prior to milling the veneer, they heat the logs in a bank of steam vaults. Rather than tearing down/rebuilding these cracked, leaking vaults they opted to inject the cracks with Spetec PUR F400, a hydrophobic flexible polyurethane grout. Replacing the vault would not only have been a lot more expensive, but it would also have resulted in a costly interruption to their milling process. No one likes downtime.

Polyurethane Leak Seal Training

Saturday is the one day of the week that the vaults are offline, and that is when I conducted the complimentary field training for their employees, who had never done any injection work before. Within a few hours, they understood how to handle the grout, how to use the grout pump, and how to accomplish their injection work. They can now self-perform their crack injection as needed.