The Environmental Stakes of Wastewater Management

The Environmental Stakes of Wastewater Management

Wastewater management is not just a logistical challenge; it's an environmental imperative. The stakes are high, and the consequences of mismanagement can be devastating. From contaminating water bodies to harming aquatic life, the environmental impact of poorly managed wastewater systems is far-reaching. As stewards of public infrastructure, municipal managers have a responsibility to not only ensure the effective treatment of wastewater but also to minimize its environmental footprint.

Eco-Friendly Technologies and Practices

Fortunately, advances in technology and best practices offer a path to more sustainable wastewater management. Here are some of the leading eco-friendly technologies and practices that can make a significant difference:

Membrane Bioreactors (MBRs)

MBRs combine conventional activated sludge treatment with membrane filtration. This technology offers higher-quality effluent and reduces the need for chemical use in wastewater treatment.

Anaerobic Digestion

Anaerobic digestion breaks down organic matter in the absence of oxygen, producing biogas that can be used for energy. This process reduces the volume of sludge and its associated disposal costs.

Phytoremediation

Using plants to remove or neutralize pollutants in water is an eco-friendly and cost-effective method. Wetlands, for example, can be engineered to treat wastewater naturally.

Energy-Efficient Pumps

Switching to energy-efficient pumps can significantly reduce the energy consumption of wastewater treatment plants, thereby lowering their carbon footprint.

Real-Time Monitoring Systems

Advanced sensors and control systems can optimize the treatment process, reducing the need for chemicals and energy.

Steps for Implementing a Green Wastewater Management Strategy

Implementing an eco-friendly wastewater management strategy requires a comprehensive approach. Here are some steps to guide municipal managers:

Conduct an Environmental Audit

The first step is to assess the current environmental impact of your wastewater treatment facilities. This audit will identify areas for improvement and help prioritize actions.

Set Clear Objectives

Define what you aim to achieve with your green wastewater management strategy. Whether it's reducing energy consumption by a certain percentage or lowering chemical use, clear objectives will guide your efforts.

Choose Appropriate Technologies

Based on your audit and objectives, select the technologies that best fit your needs. Consider factors like cost, scalability, and ease of integration with existing systems.

Train Staff

Successful implementation requires a well-trained staff. Make sure your team understands the new technologies and practices, and how they contribute to environmental sustainability.

Monitor and Adjust

Once implemented, continuously monitor the performance of your new systems. Use real-time data to make necessary adjustments and optimize efficiency.

Engage the Community

Transparency is key. Keep the community informed about your efforts to make wastewater management more eco-friendly. Public support can be a significant asset in securing future investments in green technologies.

The Importance of Using NSF-Approved Products in Repairs

When it comes to repairs involving contact with drinking water, it's crucial to determine if your project requires products that meet NSF/ANSI 61-5 standards. The National Sanitation Foundation (NSF) develops public health standards and certification programs that protect the world's food, water, consumer products, and environment. NSF ensures that adequate testing is conducted for all products used in or around drinking water from source to tap.

Each product must undergo rigorous testing to receive NSF approval. The manufacturer's plant and quality assurance practices must also pass a thorough inspection. This rigorous certification process is invaluable to all parties involved, ensuring that products meet the highest standards for safety and quality.

Moreover, compliance with NSF standards ensures that you are also in compliance with the Safe Water Drinking Act (SDWA). The SDWA gives the EPA the authority to impose criminal and civil penalties on industries that are not in compliance. In 2014, enforcement efforts netted $163 million in penalties and fines, 155 combined years of incarceration for sentenced defendants, and $16 million in court-ordered project clean-ups.

For municipal managers, using NSF-approved products in repairs is not just a best practice; it's a legal necessity. It ensures that you are not the source or cause of drinking water contamination, either in the short or long term.

The Long-Term Benefits of Eco-Friendly Practices

Adopting eco-friendly practices in wastewater management is not just good for the environment; it's also good for the community and the municipal budget. Reduced energy consumption lowers operational costs, while cleaner effluent means healthier ecosystems and, potentially, fewer regulatory hurdles. Moreover, sustainable practices can enhance a municipality's reputation, making it more attractive for both residents and businesses.

In the long run, the benefits far outweigh the initial costs and challenges of transitioning to a green wastewater management strategy. It's an investment in the future—a future where both people and the planet can thrive. Municipal managers have the opportunity, and indeed the responsibility, to lead the way in adopting sustainable, eco-friendly practices. By doing so, they safeguard not just their immediate community, but also contribute to global environmental conservation efforts.

The Critical Role of Wastewater Management in Public Health

The Critical Role of Wastewater Management in Public Health

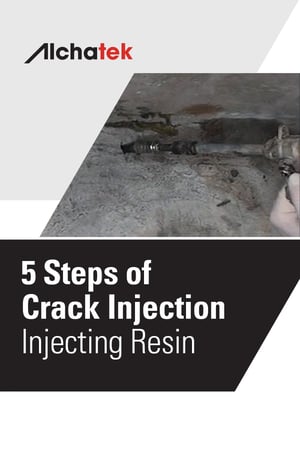

Finally! We are at the last basic step. Now for the fun part - injecting the polyurethane resin. If you only have one pump, be sure to flush the pump out completely with

Finally! We are at the last basic step. Now for the fun part - injecting the polyurethane resin. If you only have one pump, be sure to flush the pump out completely with

All cracks that aren’t actively leaking at the time you are sealing them need to be flushed out with water. Flushing them gives you several advantages:

All cracks that aren’t actively leaking at the time you are sealing them need to be flushed out with water. Flushing them gives you several advantages:

Installing high-pressure injection ports is pretty straightforward, so I won’t spend too much time on this topic. Just a few quick tips.

Installing high-pressure injection ports is pretty straightforward, so I won’t spend too much time on this topic. Just a few quick tips.

Here it is. My favorite topic. Why? Because it is my pet peeve. It separates the technicians who care from those who are only going through the motions. Quite frankly, it can be the difference between a successful outcome and dismal failure - or at the very least an expensive callback.

Here it is. My favorite topic. Why? Because it is my pet peeve. It separates the technicians who care from those who are only going through the motions. Quite frankly, it can be the difference between a successful outcome and dismal failure - or at the very least an expensive callback.

Reducing infiltration is paramount for healthy storm and wastewater collection systems. Management teams should consider cost-effective, eco-friendly, easy-to-use products. Ideal products simplify repairs through quick mobilization and installation while being effective and long-lasting.

Reducing infiltration is paramount for healthy storm and wastewater collection systems. Management teams should consider cost-effective, eco-friendly, easy-to-use products. Ideal products simplify repairs through quick mobilization and installation while being effective and long-lasting. .jpg?width=1400&height=425&name=Banner%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg)

.jpg?width=300&height=450&name=Body%20-%205%20Steps%20of%20Crack%20Injection%20-%20Drilling%20Holes%20(Continued).jpg) Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Let’s face it, most of the structures you drill through will be full of rebar. Rebar is the steel reinforcement that gives the structure its strength. Concrete protects the rebar by shielding it from moisture, and the high pH of concrete keeps the rebar from rusting. However, once a crack forms it allows more water and environmental gasses to reach the area surrounding the rebar. Carbonation of the concrete can now occur which causes the pH to drop and the corrosion process to begin. The rust expands and takes up 15 times the volume of the un-corroded steel which causes tensile forces to work against the concrete eventually resulting in additional cracking and spalling. Hopefully, you will be called in to fix the leaks before much of this damage occurs.

Inflow and Infiltration (I&I)

Inflow and Infiltration (I&I)

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.

I remember my first day on the job back in June of 1985. We were working nights in the subway tunnels of Atlanta, sealing leaks in the ceiling. The crew handed me a 30-pound hammer drill and told me to drill holes in the ceiling at a 45-degree angle. Sure, what the heck is a 45-degree angle? I put on a lot of muscle that summer drilling overhead and hauling 50-pound pails of resin all over the Southeastern U.S.