A major culvert restoration project was recently completed by Geotech Services Inc. in Ohio. The Este Ave culvert is a concrete storm sewer that runs about 1000 feet from 4861 Este Ave to Mill Creek. The culvert includes 200 pipe joints, the majority of which are not watertight, and is 108 inches in diameter. A few of the sealed joints in the culvert have failed, leading to enhanced infiltration at downstream joints. The groundwater infiltration ranges from modest seepage to major leaks. Although there aren't any voids easily seen at the surface, it's expected that some channeling has happened along the pipe's bottom. In 2008, grout was injected to seal several joints near the intake and to fill voids around the outside of the pipe. Controlled density fill was then used to fill voids at the surface around the wing wall. Since that time, the wing wall has remained stable. Unfortunately, the culvert's sealed joints have degraded, leading to more infiltration at downstream junctions.

A major culvert restoration project was recently completed by Geotech Services Inc. in Ohio. The Este Ave culvert is a concrete storm sewer that runs about 1000 feet from 4861 Este Ave to Mill Creek. The culvert includes 200 pipe joints, the majority of which are not watertight, and is 108 inches in diameter. A few of the sealed joints in the culvert have failed, leading to enhanced infiltration at downstream joints. The groundwater infiltration ranges from modest seepage to major leaks. Although there aren't any voids easily seen at the surface, it's expected that some channeling has happened along the pipe's bottom. In 2008, grout was injected to seal several joints near the intake and to fill voids around the outside of the pipe. Controlled density fill was then used to fill voids at the surface around the wing wall. Since that time, the wing wall has remained stable. Unfortunately, the culvert's sealed joints have degraded, leading to more infiltration at downstream junctions.

Powerful Polymer

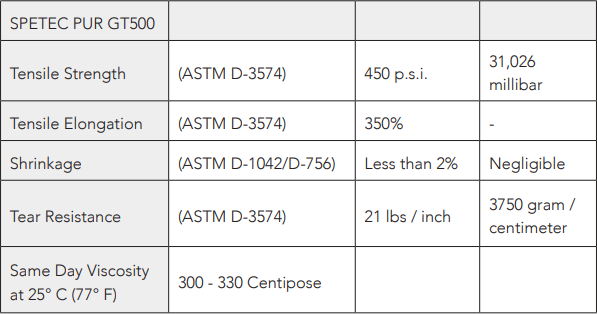

Geotech Services used Spetec PUR GT500 to seal all the pipe joints in the culvert and to fill voids around the outside of the structure. Spetec PUR GT500 is NSF/ANSI 61 approved for contact with drinking water. This single-component polyurethane resin is designed to penetrate and seal off leaks in cracks, joints, and pipe penetrations. As a hydrophilic polyurethane, it chases down water and gets into the microstructure of the concrete, forming a flexible seal and a mechanical bond with the wet concrete.

Painless Procedure

Every joint in the culvert's bottom half was leaking and allowing groundwater to seep in. Geotech Services drilled one injection hole in the middle of the culvert joint at the bottom and injected the GT500 until the joint was completely sealed. Additional holes were drilled, based on how the material was traveling. About 3500 gallons were injected overall.

Rapid Result

The entire 1000-foot culvert was sealed in just under 30 days.