-1.png?width=1024&name=conference%20room%201-banner%20(4)-1.png)

.png?width=320&name=conference%20room%201-blog%20(6).png) “If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

“If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

Who is Colt Hullander? Even if you're an experienced concrete repair industry professional, you still may not know this man by name. He started his grouting career on the contractor side directly out of high school. For the next several years, he developed key skills in the chemical grouting space with countless hours in the field lifting slabs and stabilizing soils. During these years, Colt gained priceless experience in an extremely technical process: mixing and pumping single and dual component polymer grouts through expensive multi-component proportioning equipment at high volumes to stabilize and lift very large structures in both the public and private sector. Some would say these are some of the most important skills one could have in our industry. But his commitment to his team is far more impressive.

Fast forward to Christmas weekend, 2017. Over the next four weeks, including all weekends, a typical week for Colt involved servicing field technical support, welding several custom made structures up to 10’ tall (some in aluminum!), building custom-made wood demo models with masonry block faces, designing and fabricating a custom cart for a several hundred-pound piece of equipment, and much more. Most of us would see this is a lot of work. However, the job had yet to begin.

Two weeks ago, on a Wednesday afternoon, Colt loaded up an F-350 with a 20’ trailer full of all of the above-mentioned items, and more, and left Atlanta, GA. He drove for 4 days until he reached Las Vegas on Saturday. Once there, Colt worked the entire weekend assembling an entire show display prepared for the 70,000 people that were about to come through the doors. As the Sales and Management team poured into company meetings on Monday, Colt excused himself only to return to the lot for last-minute setup well into the night-time hours. On Tuesday morning, Colt assumed his position in the booth as a live demo operator conducting live applications every 2 hours, all week long. On Friday of last week, Colt packed up all of the remaining gear and set out from Las Vegas, making the drive back to Atlanta. Three days later, Colt would be back in Atlanta, coming to work the very next day. I spoke to Colt today, and to little surprise, he was on a job-site. Colt Hullander is an Alchemy-Spetec Technical Field Services Representative, and we are very proud to have him on our team.

It’s appropriate to thank our entire team for all of their work last week at World of Concrete. Colt is certainly not the only one on our team who deserves a blog notice. And undoubtedly, many of you reading this have those teammates who went the extra mile as well. But true to the format of this People section, it was an easy choice to share the story of Colt Hullander. Well done Colt! And well done to all of those who make World of Concrete such a productive week for all attendees.

Want more information on Alchemy-Spetec products?

.png?width=320&name=Process%20and%20Applications-%20social%20(2).png) The Deep Lift

The Deep Lift

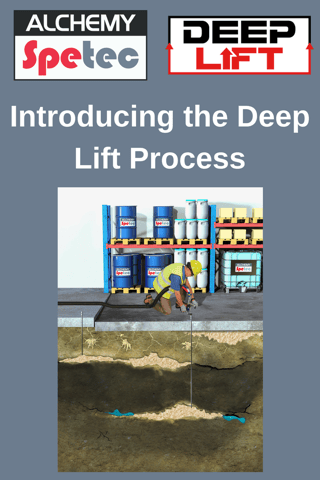

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to settling of a foundation or a roadway. Traditional slab lifting can bring concrete and structures back into place but it doesn’t necessarily address the underlying issue or guarantee a long term fix. Other methods of addressing deep soil issues require heavy equipment, extended down time, and collateral property damage. These situations create problems for property owners as well as opportunities for the elite contractors that know how to fix them.

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to settling of a foundation or a roadway. Traditional slab lifting can bring concrete and structures back into place but it doesn’t necessarily address the underlying issue or guarantee a long term fix. Other methods of addressing deep soil issues require heavy equipment, extended down time, and collateral property damage. These situations create problems for property owners as well as opportunities for the elite contractors that know how to fix them.

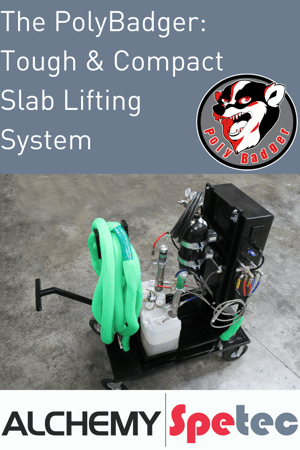

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!

-1.png?width=1024&name=conference%20room%201-banner%20(4)-1.png)

.png?width=320&name=conference%20room%201-blog%20(6).png) “If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

“If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

6. End Result

6. End Result

-1.png?width=1024&name=Polyurethane%20Soil%20Stabilization%20Explained-banner%20(1)-1.png)

.png?width=320&name=part%204-%20blog%20(1).png) The

The

.png?width=1024&name=part%201%20(4).png)

.png?width=320&name=part%201%20(3).png)