In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

The building is still home to a Presbyterian church. For years, the administrators have been simply dealing with the water by channeling it, as best they could, to sump pumps. Many and various repair attempts have been made over the years, but none of them have been successful in the long term. Recently, the church administration reached out to BJB Restoration for help with this ongoing issue. Due to the complexity of the project, Alchemy-Spetec's Director of Technical Services - Leak Seal Division Charlie "The Grout Geek" Lerman was called in to consult on the job.

Powerful Polymers

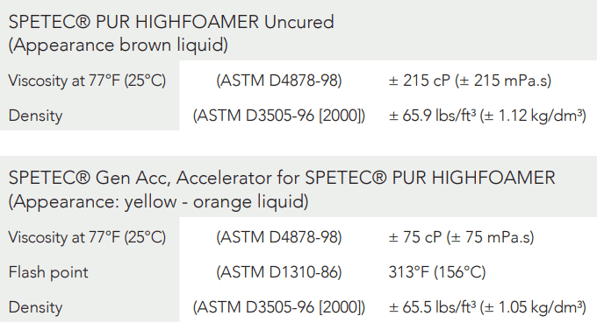

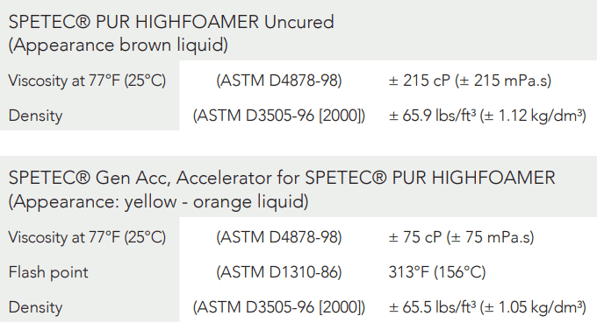

The technicians chose Spetec PUR HighFoamer as the repair material for this job because its expansive nature when catalyzed with Spetec GEN ACC Accelerator makes it a very cost-effective curtain grouting polyurethane resin. This one-component, closed-cell, hydrophobic, water-reactive, solvent, and phthalate-free, low-viscosity resin is also ideal for filling any voids created by the water underneath the basement slabs.

Painless Procedures

This particular job was what we like to call exploratory grouting, focused on two trial areas of complex cracking. The crew started injecting in the area of the primary leak. As they injected, water and foam began to bubble up along an adjacent and previously unidentified trench-like defect as well as the cracking being addressed. The initial injection covered the main crack and a surrounding area of about 16 feet (thanks to the expansive nature of Spetec PUR HighFoamer). Outgassing (CO2 produced during polymerization) was visible in numerous defects outside of that radius, requiring additional injections to seal the entire area.

Rapid Results

This one-day exploratory grouting project provided the contractor with a very accurate understanding of the type of problem and soil conditions they were dealing in the basements. The contractor and church administrators subsequently agreed upon a long-term maintenance plan based on the church's budget that calls for periodic curtain grouting over the next few years to address the many remaining basement floor defects in both buildings.

Want more information on curtain grouting?

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

In Louisville, Kentucky the Presbyterian church owned two historic buildings with an alley between them. Last century, an addition was added removing the alley and connecting the two buildings. Unfortunately, the addition was not properly waterproofed during construction. This led to water below-grade infiltration and a plethora of very complex leaking cracks and joints in the basements of both buildings and the new connecting structure.

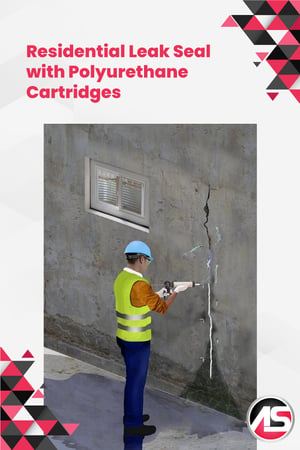

As more property owners convert basements into living spaces, the demand for residential waterproofing increases. Some standard industry practices include using a sump pump to remove leaking water or applying hydraulic cement to the leaking side of the wall (negative side waterproofing). Neither of these is an ideal solution. Hydraulic cement is very rigid once it cures, and it cracks over time due to structural movement caused by freeze/thaw cycles and expansive surrounding soil. A home is often a family’s biggest investment, so most are looking for a cost-effective, durable, long-term repair.

As more property owners convert basements into living spaces, the demand for residential waterproofing increases. Some standard industry practices include using a sump pump to remove leaking water or applying hydraulic cement to the leaking side of the wall (negative side waterproofing). Neither of these is an ideal solution. Hydraulic cement is very rigid once it cures, and it cracks over time due to structural movement caused by freeze/thaw cycles and expansive surrounding soil. A home is often a family’s biggest investment, so most are looking for a cost-effective, durable, long-term repair.

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of

This post is part of the Alchemy-Spetec Contractor Lens series, featuring views, news & case studies written by our customers. This article, written by John Knieper of

Alchemy-Spetec is proud to donate a portion of all proceeds to the Volunteer Florida Foundation's Hurricane Ian relief efforts through the end of 2023. Join us in supporting our neighbors in Florida, who were affected by Hurricane Ian.

Alchemy-Spetec is proud to donate a portion of all proceeds to the Volunteer Florida Foundation's Hurricane Ian relief efforts through the end of 2023. Join us in supporting our neighbors in Florida, who were affected by Hurricane Ian.

The Crack Injection Process

The Crack Injection Process

The Curtain Grouting Process

The Curtain Grouting Process

The Polyurethane Soil Stabilization Process

The Polyurethane Soil Stabilization Process

The Concrete Leveling Process

The Concrete Leveling Process

Alchemy-Spetec offers one-hour CE/PDH accredited presentations on polyurethane concrete repair. Presentation topics offered include Leak Seal, Geotech, and Seawall Repair. Here is a detailed overview...

Alchemy-Spetec offers one-hour CE/PDH accredited presentations on polyurethane concrete repair. Presentation topics offered include Leak Seal, Geotech, and Seawall Repair. Here is a detailed overview...