Using the best equipment is just as important as using the best material. In this post, I'll provide a brief overview of Alchemy-Spetec's equipment offerings.

Equipment Overview

MixMaster Pro

Two-component resin injection gun manufactured specifically for lifting concrete slabs and designed to handle back-pressure.

.png?width=320&name=equipment-blog%20(1).png)

Advantages:

- Two-component resin injection gun.

- Manufactured for lifting concrete slabs.

- Low operation cost.

- Handles back pressure.

- Built to last.

PMC Pumps

PMC plural component proportioners are used to inject AP two-component structural polyurethane foams for concrete leveling. Rugged and dependable, these pumps utilize relays and circuit breakers instead of circuit boards, vastly increasing reliability and preventing maintenance problems.

.png?width=320&name=equipment-blog%20(2).png)

Advantages:

- Used for concrete leveling & slab stabilization.

- Rugged and dependable.

- Uses relays instead of circuit breakers (less maintenance).

- Pumps range in output from 25 lbs/min - 40 lbs/min.

- Hydraulic or pneumatic.

Titan Pumps

Modified for injecting polyurethane resin, these world-class Titan pumps are essential tools for sealing both small and gushing leaks, as well as filling voids behind and below structures.

.png?width=320&name=equipment-blog%20(3).png)

Advantages:

- Customized for crack injection.

- Output range of .54 gal/min - 2.35 gal/min.

- Pressure range of 3300 psi - 3600 psi.

- Seals both small and gushing leaks.

- Can also be used for some soil stabilization and void fill projects.

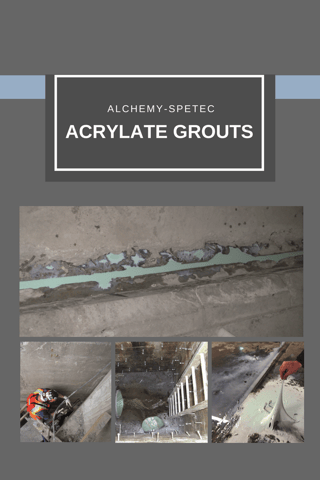

Acrylates were introduced in the early 80s to the waterproofing industry as a less toxic alternative to

Acrylates were introduced in the early 80s to the waterproofing industry as a less toxic alternative to .png?width=899&height=273&name=Waterstop-banner%20(1).png)

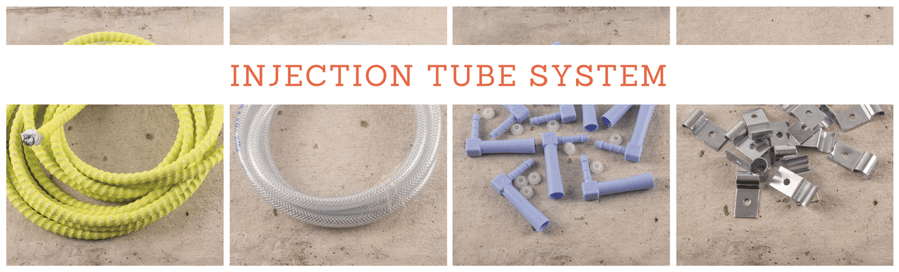

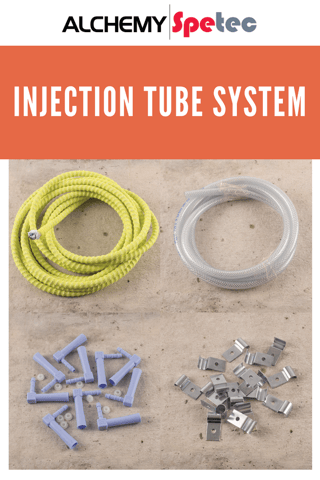

The Spetec ITS Kit (Injection Tubing System) is used as a complete and primary waterstop system for post-injection sealing of construction joints in concrete. It is used to seal cold joints, expansion joints, pipe penetrations, and tunnel segment joints. This kit includes four parts:

The Spetec ITS Kit (Injection Tubing System) is used as a complete and primary waterstop system for post-injection sealing of construction joints in concrete. It is used to seal cold joints, expansion joints, pipe penetrations, and tunnel segment joints. This kit includes four parts:

What Can You Do?

What Can You Do?

.png?width=899&height=273&name=SST500-banner%20(3).png)

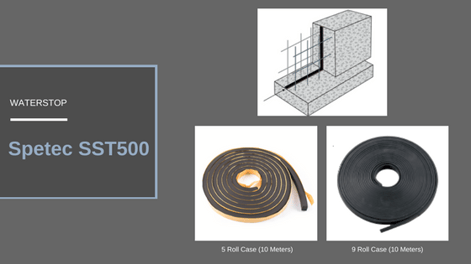

.png?width=320&name=SST500-blog%20(1).png) ST500 is a black hydrophilic synthetic waterproofing strip that is designed to fasten to existing joints.

ST500 is a black hydrophilic synthetic waterproofing strip that is designed to fasten to existing joints.

Some call it redundancy. Some call it insurance. Most everyone agrees it's a good idea.

Some call it redundancy. Some call it insurance. Most everyone agrees it's a good idea. .png?width=899&height=273&name=epicol-banner%20(1).png)

.png?width=320&name=epicol-blog%20(2).png)

.png?width=899&height=273&name=NSF-banner%20(1).png)

.png?width=320&name=NSF-blog%20(2).png) The Safe Drinking Water Act (SDWA) gives the EPA latitude to impose criminal and civil penalties on industries not in compliance. In 2014 enforcement efforts policing clean water netted $163 million in penalties and fines, 155 combined years of incarceration for sentenced defendants, and $16 million in court-ordered project clean-ups.

The Safe Drinking Water Act (SDWA) gives the EPA latitude to impose criminal and civil penalties on industries not in compliance. In 2014 enforcement efforts policing clean water netted $163 million in penalties and fines, 155 combined years of incarceration for sentenced defendants, and $16 million in court-ordered project clean-ups..png?width=899&height=273&name=h40-banner%20(1).png)

.png?width=320&name=h40-blog%20(2).png) Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles and decomposition.

Unstable soil can be defined as soil that will not stay in place on its own, and therefore requires extra support. It should be noted that unstable soil can threaten the stability, security, and safety of infrastructure and can damage, degrade, and even destroy a number of structures, such as buildings, bridges, and roads. There are a variety of factors that can cause unstable soil including erosion, poor compaction, freeze/thaw cycles and decomposition.