Product

Product

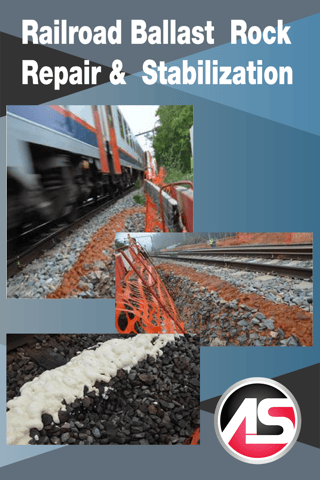

AP Lift 475 is a two-component polyurethane chemical grout resin system (1:1 ratio) developed for the reinforcement and stabilization of loose bulk ballast stones on railway tracks.

Procedure

AP Lift 475 is mixed together, then poured on the ballast stones to increase the rigidity and stiffness of ballast. When applied, this product is a weather resistant solution that reduces vibrations and provides a buffer zone from the concrete slab track to the ballast track. AP Lift 475 helps to reinforce the ballast, reduce loose stones and dust, as well as prevent pulverization. The AP Lift 475 also provides an excellent binder for stabilization of the ballast, so when excavation is needed under the ballast and the tracks, for applications like Micro-tunnelling, AP Lift 475 will bind the ballast together to prevent cave-ins from occuring.

Solution

For rail infrastructure, compliance of Polyurethane Stabilized Ballasts may be favorable due to the strains that can be tolerated under the loads distributed from the superstructure down through the substructure. Large differences in mechanical behavior of clean ballast before and after polyurethane stabilization indicate that the introduction of Rigid Polyurethane Foam to ballast creates a geocomposite, referred to herein as polyurethane stabilized ballast, with different and generally superior mechanical properties to that of clean ballast, recycled ballast, and fouled ballast. Excerpted from “Mitigating Ballast Fouling Impact and Enhancing Rail Freight Capacity” by the National Center for Freight & Infrastructure Research and Education.

There are many ways to seal leaks in concrete structures. One of the oldest methods uses water to activate polyurethane chemical grout to either bond to the concrete to form a watertight seal or to fill voids, and stabilize concrete.

There are many ways to seal leaks in concrete structures. One of the oldest methods uses water to activate polyurethane chemical grout to either bond to the concrete to form a watertight seal or to fill voids, and stabilize concrete.

If you are a concrete repair contractor, you may at some point want to make cold calls to gain new business. Calling on new prospects can be very frustrating if you are not used to it. Cold calling can be done by phone or in person. Before you even contact your prospect, make sure to do as much research on them as possible. Once you’ve thoroughly researched your prospect, you can make an initial contact.

If you are a concrete repair contractor, you may at some point want to make cold calls to gain new business. Calling on new prospects can be very frustrating if you are not used to it. Cold calling can be done by phone or in person. Before you even contact your prospect, make sure to do as much research on them as possible. Once you’ve thoroughly researched your prospect, you can make an initial contact.

Old Packaging

Old Packaging-1.png?width=560&height=315&name=design%20(1)-1.png)

.png?width=1024&name=conference%20room%201-banner%20(10).png)

Perhaps even more eloquent than e=mc2 is Isaac Newton’s Second Law of motion, F=ma. For all of those fellow physics enthusiasts out there, we all know how F=ma is the flathead screwdriver in the formula toolbox; and for good reason. The amount of Force generated by any individual object being equal to the object’s mass multiplied by the acceleration of that object has profound proofs across the universe that can also be observed in our everyday partnerships.

Perhaps even more eloquent than e=mc2 is Isaac Newton’s Second Law of motion, F=ma. For all of those fellow physics enthusiasts out there, we all know how F=ma is the flathead screwdriver in the formula toolbox; and for good reason. The amount of Force generated by any individual object being equal to the object’s mass multiplied by the acceleration of that object has profound proofs across the universe that can also be observed in our everyday partnerships.

.png?width=1024&name=conference%20room%201-banner%20(9).png)

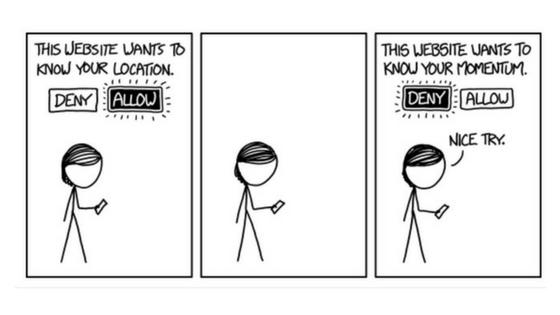

In 1927, a German physicist, Werner Heisenberg, introduced what would become the Heisenberg Uncertainty Principle. In short, his theory maintained that two very distinctive properties when examining any particle, location and momentum, could not be accurately measured at the same time. The more one knows about one value, the less it knows about the other. So how does this relate to business?

In 1927, a German physicist, Werner Heisenberg, introduced what would become the Heisenberg Uncertainty Principle. In short, his theory maintained that two very distinctive properties when examining any particle, location and momentum, could not be accurately measured at the same time. The more one knows about one value, the less it knows about the other. So how does this relate to business? .png?width=560&height=315&name=Untitled%20design%20(1).png) The physical world around us is made up of particles. You, me, the buildings we work in, and the computer screen you’re looking at; all made up of particles. So, let’s be careful on the amount of granularity that we all aim to achieve in decision making processes. The often-quoted phenomenon of analysis paralysis lies in the Uncertainty Principle. The more you examine one aspect of any given part of the physical world, products and opportunities included, the less you know about another aspect. There’s no way around this.

The physical world around us is made up of particles. You, me, the buildings we work in, and the computer screen you’re looking at; all made up of particles. So, let’s be careful on the amount of granularity that we all aim to achieve in decision making processes. The often-quoted phenomenon of analysis paralysis lies in the Uncertainty Principle. The more you examine one aspect of any given part of the physical world, products and opportunities included, the less you know about another aspect. There’s no way around this.

.png?width=320&name=injection-blog%20(2).png) When you set out to work on a leak seal injection project, it's important to be prepared.

When you set out to work on a leak seal injection project, it's important to be prepared. .png?width=1024&name=leaking%20joints-banner%20(1).png)

.png?width=320&name=leaking%20joints-blog%20(2).png)

.png?width=320&name=Process%20and%20Applications-%20social%20(2).png) The Deep Lift

The Deep Lift

-1.png?width=1024&name=mechanical%20packer-banner%20(4)-1.png)

.png?width=320&name=mechanical%20packer-blog%20(3).png) Continuing on from the previous overview of

Continuing on from the previous overview of