Product

Product

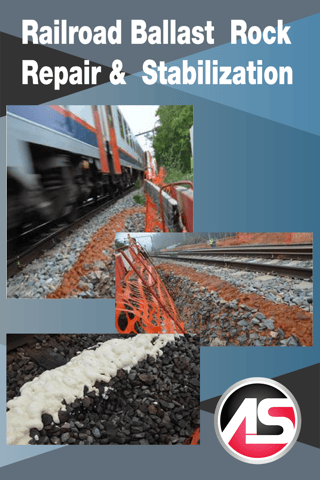

AP Lift 475 is a two-component polyurethane chemical grout resin system (1:1 ratio) developed for the reinforcement and stabilization of loose bulk ballast stones on railway tracks.

Procedure

AP Lift 475 is mixed together, then poured on the ballast stones to increase the rigidity and stiffness of ballast. When applied, this product is a weather resistant solution that reduces vibrations and provides a buffer zone from the concrete slab track to the ballast track. AP Lift 475 helps to reinforce the ballast, reduce loose stones and dust, as well as prevent pulverization. The AP Lift 475 also provides an excellent binder for stabilization of the ballast, so when excavation is needed under the ballast and the tracks, for applications like Micro-tunnelling, AP Lift 475 will bind the ballast together to prevent cave-ins from occuring.

Solution

For rail infrastructure, compliance of Polyurethane Stabilized Ballasts may be favorable due to the strains that can be tolerated under the loads distributed from the superstructure down through the substructure. Large differences in mechanical behavior of clean ballast before and after polyurethane stabilization indicate that the introduction of Rigid Polyurethane Foam to ballast creates a geocomposite, referred to herein as polyurethane stabilized ballast, with different and generally superior mechanical properties to that of clean ballast, recycled ballast, and fouled ballast. Excerpted from “Mitigating Ballast Fouling Impact and Enhancing Rail Freight Capacity” by the National Center for Freight & Infrastructure Research and Education.