.png?width=899&height=273&name=mechanical%20packer-banner%20(2).png)

.png?width=320&name=mechanical%20packer-blog%20(1).png) The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

The term ‘Mechanical Packer’ probably doesn’t mean much to those not in the concrete repair industry. But for those close to chemical grouting, this term certainly brings about thoughts of both form and function. Mechanical packers are also referred to as ports, or more simply, packers. But we would like to be very clear that a port is not a packer.

Mechanical packers were designed to withstand high pressure injection applications by inserting them into pre-drilled holes in a concrete substrate at various diameters ranging most commonly from 1/4" – 5/8”. Mechanical packers feature a rubber base with a threaded shaft. As the threaded shaft is tightened, the rubber base is compressed, creating a compression seal inside the drill hole. The ultimate pressure tolerance is dependent upon the amount the rubber is expanded and the total surface area of the rubber base that is in contact with the drill hole. That is, a smaller diameter packer will have considerably less surface area of rubber compressed against the concrete side walls, and thus holding a lower amount of pressure when connected to high pressure equipment. Most job site and substrate conditions will permit successful injection results with a diameter of 3/8” – 1/2". Of course, some contractors have personal preference of smaller or larger sizes.

Concrete packers also come in various types. Suppliers will market benefits of steel, brass, zinc, or aluminum. All things considered, steel packers tend to be the most versatile packers as they are compatible with all chemical grout types, while the brass, aluminum, and zinc can exhibit signs of deterioration when using oxidizing agents such as the salt component in a polyacryate gel. However, some contractors insist that the breakdown is not as quick as marketed by suppliers, therefore utilizing brass and aluminum packers in these applications as well.

Each packer features an anti-return ball valve that is opened under pressure, allowing the passage of chemical grouts. Upon depressurizing, the ball valve will close, prohibiting the return flow of the injection resin out of the drill hole. This ball valve can be located on the top of the packer, in the base of the packer, or even freely-floating in the packer shaft to allow for maximum flow. There are pros and cons to each ball valve location depending on job site condition and application and finishing techniques.

Lastly, there are plastic alternatives commonly referred to as ‘bang-in’ or ‘hammer-in’. These packers do not have the threaded metal shaft, but as they are driven into the drill hole, the same compression seal theory takes hold as the tapered edges become lodged into the drill hole sides. Another form of plastic ports is a plastic, surface-mounted version that is commonly used in epoxy injection and/or in the event that drilling into the substrate would be considered harmful or ill-advised.

For more detail on your specific project needs and packer or port recommendation, please contact a knowledgeable Alchemy-Spetec representative at 404-618-0438. Alchemy-Spetec offers all of the packers and ports listed above, as well as all of the chemical grouts and pumping systems required to make your next chemical grouting job a success!

Want more information on Alchemy-Spetec mechanical packers?

.png?width=1024&name=conference%20room%201-banner%20(8).png)

.png?width=320&name=conference%20room%201-blog%20(12).png) "No matter how great the talent or effort, some things just take time. You can’t produce a baby in one month by getting nine women pregnant.”

"No matter how great the talent or effort, some things just take time. You can’t produce a baby in one month by getting nine women pregnant.”

.png?width=1024&name=conference%20room%201-banner%20(7).png)

.png?width=320&name=conference%20room%201-blog%20(11).png) “

“

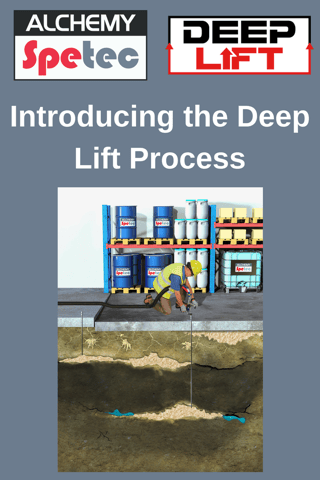

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to settling of a foundation or a roadway. Traditional slab lifting can bring concrete and structures back into place but it doesn’t necessarily address the underlying issue or guarantee a long term fix. Other methods of addressing deep soil issues require heavy equipment, extended down time, and collateral property damage. These situations create problems for property owners as well as opportunities for the elite contractors that know how to fix them.

Poor compaction, water erosion, broken pipes, and organic material in the soil can all lead to settling of a foundation or a roadway. Traditional slab lifting can bring concrete and structures back into place but it doesn’t necessarily address the underlying issue or guarantee a long term fix. Other methods of addressing deep soil issues require heavy equipment, extended down time, and collateral property damage. These situations create problems for property owners as well as opportunities for the elite contractors that know how to fix them.

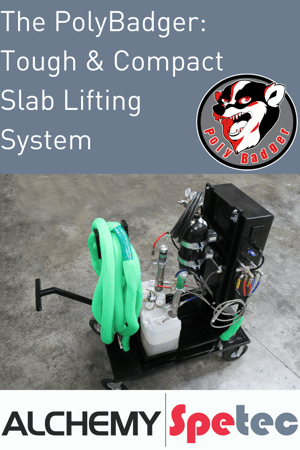

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!

The Alchemy-Spetec PolyBadger lifting system is tough and compact. This system is an affordable entry-level slab lifting option for new contractors, as well as an extremely portable addition to the experienced contractor’s arsenal. The PolyBadger is a lot less expensive than your standard 20 foot trailer rig. The set up is simple and requires minimal equipment. The entire system can easily fit in the back of a pickup truck!

.png?width=1024&name=conference%20room%201-banner%20(5).png)

.png?width=320&name=conference%20room%201-blog%20(9).png)

-1.png?width=1024&name=conference%20room%201-banner%20(4)-1.png)

.png?width=320&name=conference%20room%201-blog%20(6).png) “If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

“If you don’t love something, you’re not going to go the extra mile, work the extra weekend, challenge the status quo as much.” – Steve Jobs

6. End Result

6. End Result

-1.png?width=1024&name=Polyurethane%20Soil%20Stabilization%20Explained-banner%20(1)-1.png)

.png?width=899&height=273&name=woc-banner%20(2).png)

.png?width=320&name=woc-blog%20(1).png)