Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

This is why I love articles like this one from PileBuck.com. It gives a good overview of seawalls and bulkheads. These structures are often the frontline in our war against erosion and thus require periodic maintenance. We at Alchemy-Spetec are committed to providing cost-effective, high-quality grouts tailored to the precise needs of the project. We know that a quality grout is just the beginning and we follow-through with the most experienced technical support in the industry. Enjoy the article...

Along bluffs and coastal shorelines, various structures are often necessary to protect beaches from wave action, or to retain fill or in situ soil. There are three primary structure types that can be utilized to accomplish these goals, including protective materials laid on slopes, known as revetments, and vertical structures, which are classified as either seawalls or bulkheads.

Revetments are typically constructed of stone or other durable materials to provide protection for designated slopes. They are built with an armor layer, a filter layer or layers, and toe protection. The armor layer can consist of interlocking structural elements designed to form a geometric pattern, or a random mass or stone or concrete rubble. Next, a filter layer will ensure drainage and protection of the underlying soil. Finally, toe protection will offer stability against undermining at the base of the revetment.

While bulkheads and seawalls are both types of vertical structures used to protect coasts, they have different purposes. Bulkheads are used to retain or prevent the sliding of land, with protection of the upland area from wave action as a secondary consideration. In contrast, the primary purpose of seawalls is to intercept waves. Bulkheads can be cantilevered, anchored, or gravity structures, with their use limited to areas where wave action can be resisted by the types of materials used in these respective designs (such as sheet piling or rock-filled timber cribs). For areas where intense wave action exists, massive concrete seawalls are the more appropriate choice, with either a vertical, concave, or stepped seaward face.

Read the rest at PileBuck.com...

Want more info Alchemy-Spetec products?

I often get asked about pre-drilling for crack injection. Pre-drilling is the practice of putting all the ports in position before injecting anything. This preparation procedure can often be very time efficient. Think of this an assembly line approach. Pre-drilling is often done when there is “shut-down” period on a job with a limited time to get the work done. You’ll encounter these types of jobs in subway systems, for example, when the work needs to be done while the trains aren’t running. That’s just one specific example, but you get the idea.

I often get asked about pre-drilling for crack injection. Pre-drilling is the practice of putting all the ports in position before injecting anything. This preparation procedure can often be very time efficient. Think of this an assembly line approach. Pre-drilling is often done when there is “shut-down” period on a job with a limited time to get the work done. You’ll encounter these types of jobs in subway systems, for example, when the work needs to be done while the trains aren’t running. That’s just one specific example, but you get the idea.

Port spacing in the case of crack injection has nothing to do with the distance between a port in Miami and a port in Jamaica. In this case, we are simply discussing how far apart to place your injection ports. This is not a fixed distance, as proper port spacing varies depending on site conditions.

Port spacing in the case of crack injection has nothing to do with the distance between a port in Miami and a port in Jamaica. In this case, we are simply discussing how far apart to place your injection ports. This is not a fixed distance, as proper port spacing varies depending on site conditions.

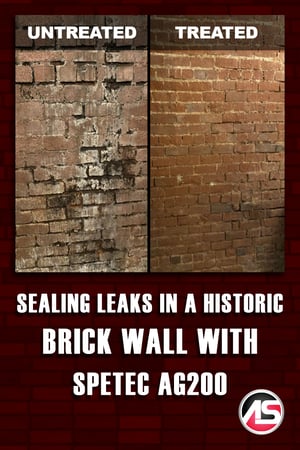

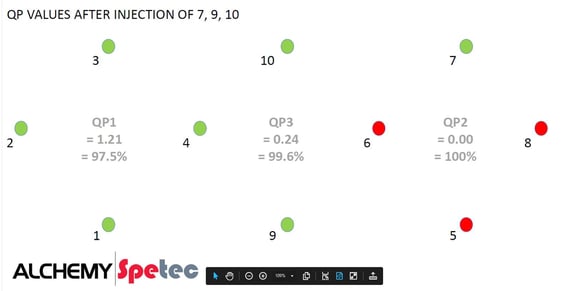

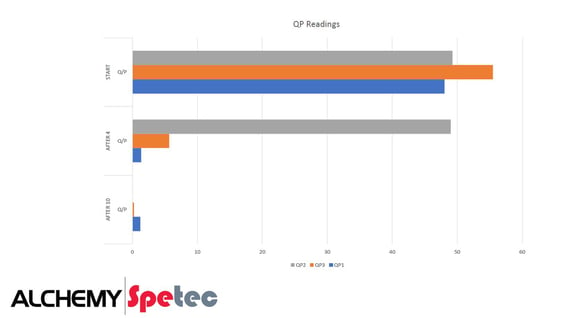

As the Director of Technical Services for the Leak Seal division at Alchemy-Spetec, I often find myself assisting customers with some interesting jobs. Such was the case when I was called in to consult with a contractor who was sealing a leak in a historic district below-grade, multi-course brick wall. As is often the case with below grade, historic spaces, water infiltration was unsightly, gave off a musty odor, and was damaging to finishes. This was a very old brick wall, approximately 8 x 15 feet in size and at least three courses thick. The owner wanted to find a way to waterproof this vintage brick structure while at the same time preserving its unique appearance. In addition to the water flow issue, the leaks were causing mold/mildew on the walls.

As the Director of Technical Services for the Leak Seal division at Alchemy-Spetec, I often find myself assisting customers with some interesting jobs. Such was the case when I was called in to consult with a contractor who was sealing a leak in a historic district below-grade, multi-course brick wall. As is often the case with below grade, historic spaces, water infiltration was unsightly, gave off a musty odor, and was damaging to finishes. This was a very old brick wall, approximately 8 x 15 feet in size and at least three courses thick. The owner wanted to find a way to waterproof this vintage brick structure while at the same time preserving its unique appearance. In addition to the water flow issue, the leaks were causing mold/mildew on the walls.

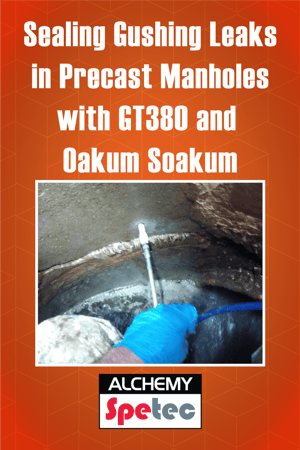

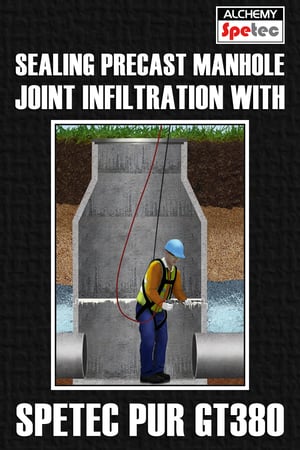

Major water infiltration in precast manholes often occurs at the pipe penetrations. Failure to seal these leaks quickly could lead to the loss of thousands of dollars. It can also suck in soils and fine particlesThis process creates voids outside the manhole. With time, these voids grow larger and become sinkholes.

Major water infiltration in precast manholes often occurs at the pipe penetrations. Failure to seal these leaks quickly could lead to the loss of thousands of dollars. It can also suck in soils and fine particlesThis process creates voids outside the manhole. With time, these voids grow larger and become sinkholes.

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

What happens when a joint in a precast manhole begins to leak? The answer is it may as well be leaking money.

In this post, we’re profiling

In this post, we’re profiling

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

Chemical grouts have an amazingly diverse range of properties. This makes them incredibly useful for all types of waterproofing, soil modification, and structural repairs. This wide range of characteristics means that there is no one size fits all grout out there. But I get ahead of myself. Before one can select a chemical grout for a repair it is necessary to understand not only the asset to be repaired but also how and why it is failing and/or leaking. There are numerous methodologies that can be utilized to determine what is going on, but before one can start the troubleshooting one needs to understand the structure's design.

We all know the destructive power of earthquakes, hurricanes, and other forces of nature and while I was aware of expansive soils, I had no idea the amount of damage they cause. We at Alchemy-Spetec focus on industry education, so I am pleased to share this video about expansive soils from Grady Hillhouse at

We all know the destructive power of earthquakes, hurricanes, and other forces of nature and while I was aware of expansive soils, I had no idea the amount of damage they cause. We at Alchemy-Spetec focus on industry education, so I am pleased to share this video about expansive soils from Grady Hillhouse at