Concrete will crack – that is a fact. When cracks appear, they are dynamic or static, and structural or non-structural. If the crack is static, non-structural, and does not leak, epoxies are great to restore design strength. However, since concrete constantly shrinks, expands, and often leaks, the use of a flexible polyurethane resin to permanently seal active leaks is the optimum choice to create a leak-free environment.

Water leaking through concrete is as old as concrete itself. Any leaking structure is problematic. These issues range from reduced lifespan to liability and lawsuits. This paper will discuss the mitigation of leaking structures to facilitate its coating. Often, these cracks are dynamic in nature. Static or structural repair of dynamic cracks will fail when the concrete needs to “move” again. Flexible polyurethane grouts can be used to mitigate water intrusion. This will extend the life of the structure and is a crucial step in surface preparation for most coatings.

Why Concrete Cracks

Concrete will crack - that is a fact. But to treat the crack, you need to understand the nature of cracking. There are four categories of cracks: static, dynamic, structural and non-structural. A crack normally falls into two of the four categories. Just as the names imply, a static crack is non-moving, and a dynamic crack moves. Structural cracks place the integrity of the structure in jeopardy, while non-structural cracks can be eyesores and allow water infiltration.

Static cracks are the result of a one-time event. This may be a thermal or shrinkage crack that formed while the concrete cured, or from a damaging event like a car hitting the concrete. Typically, these structures do not move which is the driving force to why they are no longer used today.

Dynamic cracks expand and contract due to reoccurring force(s). The forces include, but are not limited to, freeze/thaw cycles, rapid thermal changes, loading of the concrete, and expansive soils. If the joint’s design was not adequate to deal with these forces, the concrete will often crack. “Cracking in concrete is affected by the long-term conditions to which the concrete element is subjected. In most cases, long-term exposure and long-term loading extend the magnitude of cracks, principally their width, in both reinforced and plain concrete." (ACI 22R-01 2001).

External forces are usually repetitive and cause the crack to expand and contract. These cracks are not a structural concern, but water infiltration through these cracks can be a serious problem.

Epoxy vs. Flexible Polyurethane

In spite of the best efforts of the architect, engineer and contractor, structures will sometimes move in unanticipated ways causing cracks to appear. Resin can be injected into the concrete to accomplish one of two purposes:

- Restore design strength

- Stop water leakage

If load bearing members such as walls, beams or columns are weakened, injection of high strength epoxies may be appropriate. However, more often than not, the concern with cracking is water infiltration. Epoxies are designed to be strong with little to no elongation, and chemically bond the concrete back together which is not appropriate for a dynamic, leaking crack. Epoxy will be stronger than the concrete and will cause the concrete to crack nearby. Lastly, the majority of epoxies are water intolerant and not suitable for waterproofing.

Crack / Joint Injection

Examination of the crack or joint after cleaning tells us where the crack goes and how wide it is. The surface should be cleaned mechanically. Loose debris or patches should be removed to reveal the crack. To maximize results, it is best to inject an actively leaking crack.

Injection should start from the lowest point of a vertical crack or the narrowest side of a horizontal crack. Injection holes should be drilled at a distance away from the crack that is equal to half the wall’s thickness (Example: If the wall is 8” thick, drill your hole 4” from the crack). This forms an isosceles right triangle when drilling at a 45 degree angle, and ideally intersects the crack or joint at its halfway point through the wall.

A low viscosity, flexible polyurethane grout should be injected. Polyurethane grout will react with water to form a “custom gasket” that has three different bonds - adhesive, mechanical, and compressive. “The aim of all injection processes is to obtain uniform penetration of the resin and complete filling of the crack.” (Perkins 2003). Urethanes are very chemical resistant, but always check with the manufacturer about specific chemical resistances for a project.

Patience is important in resin injection work - slow is better. Always start injecting with the pump set at the lowest setting. I like to say “If crack injection is not slow and painful, you are doing it wrong.”

Case Study: Vault Coating Failure

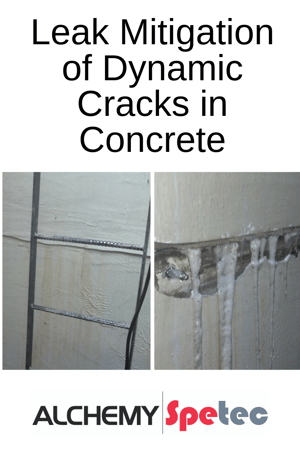

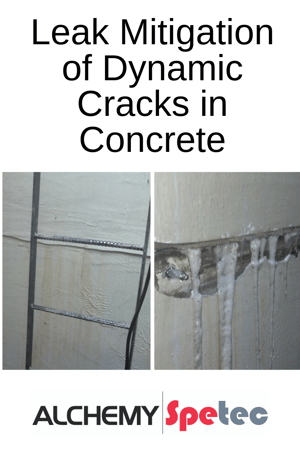

A below grade concrete precast vault was epoxy coated during a summer, the dry season, in the Pacific Northwest. The following winter coating failure was observed only at the joint. There was also indication of water intrusion and rundown (see Photo 1).

Photo 1

Inspection of the vault lead to the belief the failure was caused be water intrusion through the precast joint. In 2012 the joint was injected with a flexible hydrophobic grout (Photo 2).

Photo 2

After a number of months of observation with no water intrusion the coating was repaired and is still in service till today with no defects.

Curtain Grouting

Curtain grouting is a method of installing a waterproofing membrane on the positive side of a below-grade structure without excavation. Curtain grouting is appropriate when there is spider web cracking or extensive cracking of the concrete. It is not possible to address a large number of cracks in proximity with crack injection due to the number of injection holes needed. Often, curtain grouting is easier than crack injection, but more material intensive. Curtain grouting is an excellent fix because even if the concrete continues to crack, there will be no leaks as the water is no longer in contact with the structure.

Summary

A coating manufacturer once stated “It is estimated that 85%+ coating and lining failures are due to inadequate surface preparation.” Moisture mitigation is a large percentage of that and must be addressed. For dynamic cracks, flexible polyurethanes are one of the best repair methods out there.

Want more information on Alchemy-Spetec leak seal products?

Embedded below is a crack and curtain grouting video demo I recently recorded. For those not familiar with me, my name is Charlie Lerman. I'm the Director of Technical Services for the Leak Seal Division at Alchemy-Spetec (and I'm also known as the Grout Geek). I have been involved in a wide variety of grouting jobs from dams to tunneling, municipal to sewer system work, residential, commercial, and industrial.

Embedded below is a crack and curtain grouting video demo I recently recorded. For those not familiar with me, my name is Charlie Lerman. I'm the Director of Technical Services for the Leak Seal Division at Alchemy-Spetec (and I'm also known as the Grout Geek). I have been involved in a wide variety of grouting jobs from dams to tunneling, municipal to sewer system work, residential, commercial, and industrial.

I'd like to share a case study from a job that I recently consulted on with one of our contractor customers.

I'd like to share a case study from a job that I recently consulted on with one of our contractor customers.

.png?width=300&name=Watch%20Educational%20Leak%20Seal%20Presentations%20at%20World%20of%20Concrete%202020%20(3).png)

.png?width=899&name=Repairing%20Dams%20with%20Polyurethane%20(5).png)

.png?width=300&name=Repairing%20Dams%20with%20Polyurethane%20(4).png) Dams Across the U.S. in Dire Need of Repair

Dams Across the U.S. in Dire Need of Repair

.png?width=300&name=Seawall%20Repair%20on%20Waterfront%20Properties%20(1).png) Signs of Seawall Distress

Signs of Seawall Distress

.png?width=300&name=Sealing%20Leaks%20in%20Elevator%20Pits%20(1).png)

.png?width=899&name=Polyurethane%20Leak%20Sealing%20Explained%20(3).png)

-1.png?width=300&name=Jump%20Start%20Your%20New%20Concrete%20Leveling%20Business%20with%20Alchemy-Spetecs%20Fall%202019%20Training%20(1)-1.png) Jump start your leak seal business at

Jump start your leak seal business at