Engineering soil with polyurethane, an innovative and increasingly popular approach, encompasses both soil stabilization and concrete leveling techniques that offer minimally invasive solutions for a wide range of geotechnical and construction applications. These techniques involve injecting expandable polyurethane foam into problematic soils to fill voids, compact loose particles, and create a stable foundation, addressing instability and enhancing structural support. Engineers and property owners now have access to a solution known for its efficiency, versatility, and long-lasting results.

Engineering soil with polyurethane, an innovative and increasingly popular approach, encompasses both soil stabilization and concrete leveling techniques that offer minimally invasive solutions for a wide range of geotechnical and construction applications. These techniques involve injecting expandable polyurethane foam into problematic soils to fill voids, compact loose particles, and create a stable foundation, addressing instability and enhancing structural support. Engineers and property owners now have access to a solution known for its efficiency, versatility, and long-lasting results.

Engineering Soil: Stabilization with Polyurethane

Various factors can cause soil instability, including erosion from poor drainage, inadequately compacted fill dirt, freezing and thawing cycles, and the decay of buried organic material. If left unaddressed, these issues can lead to foundation settling, cracking, and other structural problems that compromise a building's integrity and safety. However, the polyurethane injection process fills voids, permeates and binds loose soil particles, and creates a stable, solid base for structures.

Engineering Soil: Concrete Leveling with Polyurethane

Moreover, polyurethane concrete leveling is an effective method for lifting sunken slabs. When concrete settles due to unstable soil conditions, technicians inject expandable polyurethane beneath the affected area. First, they drill small, strategically placed holes in the slab. Then, they inject the polyurethane. As the foam expands, it fills voids beneath the slab and lifts it to the desired elevation. Additionally, it compresses the surrounding soil, providing a stable base for the newly leveled slab.

Advantages of Polyurethane

Furthermore, polyurethane offers several advantages compared to other soil stabilization materials. For instance, the application process is minimally invasive, requiring only small injection holes. Additionally, the material expands and cures quickly, resulting in fast, long-lasting repairs. Moreover, polyurethane foams feature high compressive strengths, making them suitable for supporting a wide variety of structures.

Consult an Experienced Professional

To ensure successful soil stabilization, collaborating with experienced professionals who specialize in polyurethane injection is essential. For property owners, working with skilled contractors who possess the knowledge, equipment, and expertise to execute the stabilization process effectively is crucial. By partnering with a reputable contractor, property owners can achieve lasting soil stability and protect their structures.

Similarly, engineers may require the assistance of an experienced consultant when designing specifications for geotechnical projects. Alchatek's consultants provide valuable insights into material selection, injection techniques, and quality control measures. By engaging with a knowledgeable consultant, engineers can ensure that projects are designed and executed to the highest standards, thus maximizing the benefits of polyurethane applications.

In conclusion, Alchatek, a leading manufacturer of polyurethane repair materials, offers innovative solutions and technical support for property owners and engineers alike.

Fill out this form or call 404-618-0438 for a contractor referral today!

Alchatek is a leading

Alchatek is a leading

When it comes to construction and infrastructure development, the stability of soil is paramount. Property owners, managers, and builders must ensure that the ground beneath structures is solid and dependable. In situ soil stabilization with polyurethane foam offers an innovative solution to this challenge.

When it comes to construction and infrastructure development, the stability of soil is paramount. Property owners, managers, and builders must ensure that the ground beneath structures is solid and dependable. In situ soil stabilization with polyurethane foam offers an innovative solution to this challenge.

Ensuring the stability of your property's slopes is crucial. After all, unstable slopes can cause erosion, damage foundations, and create safety hazards. Fortunately, polyurethane injection is an effective and minimally invasive method for slope stabilization. This article explains how contractors use polyurethane to stabilize slopes.

Ensuring the stability of your property's slopes is crucial. After all, unstable slopes can cause erosion, damage foundations, and create safety hazards. Fortunately, polyurethane injection is an effective and minimally invasive method for slope stabilization. This article explains how contractors use polyurethane to stabilize slopes.

Pressure grouting, also known as permeation grouting, stabilizes and strengthens weak or loose soil. This process involves injecting a fluid grout mixture under pressure into the ground. As a result, the grout fills voids, cracks, and spaces between soil particles. While cement grout is often associated with pressure grouting, polyurethane grout offers several advantages.

Pressure grouting, also known as permeation grouting, stabilizes and strengthens weak or loose soil. This process involves injecting a fluid grout mixture under pressure into the ground. As a result, the grout fills voids, cracks, and spaces between soil particles. While cement grout is often associated with pressure grouting, polyurethane grout offers several advantages.

Unstable ground conditions can cause significant damage to structures built on sandy soils. However, sand stabilization with permeation grouting offers a solution to this problem by stabilizing loose sandy soils to create a solid base. This article explains the stabilization process.

Unstable ground conditions can cause significant damage to structures built on sandy soils. However, sand stabilization with permeation grouting offers a solution to this problem by stabilizing loose sandy soils to create a solid base. This article explains the stabilization process.

If you're searching for a soil stabilization company, you've probably noticed signs of unstable soil around your property, such as cracks or sinking in your patios, walkways, or pool decks. Unstable soil can lead to serious structural issues, but the right soil stabilization contractor can provide a lasting solution. Understanding the soil remediation process is an essential prerequisite for accurately evaluating soil stabilization companies.

If you're searching for a soil stabilization company, you've probably noticed signs of unstable soil around your property, such as cracks or sinking in your patios, walkways, or pool decks. Unstable soil can lead to serious structural issues, but the right soil stabilization contractor can provide a lasting solution. Understanding the soil remediation process is an essential prerequisite for accurately evaluating soil stabilization companies.

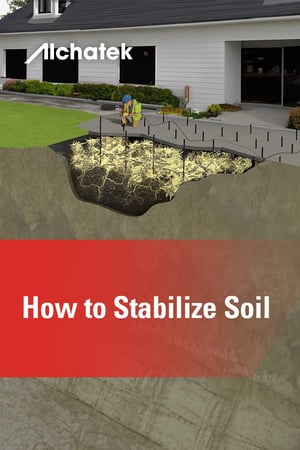

If you've noticed cracks or sinking in your patios, walkways, pool decks, or other slabs, the problem may lie beneath the surface. In fact, unstable soil around your home can lead to serious structural issues. But don't panic - there is a lasting solution. Keep reading to learn more about how to stabilize soil.

If you've noticed cracks or sinking in your patios, walkways, pool decks, or other slabs, the problem may lie beneath the surface. In fact, unstable soil around your home can lead to serious structural issues. But don't panic - there is a lasting solution. Keep reading to learn more about how to stabilize soil.

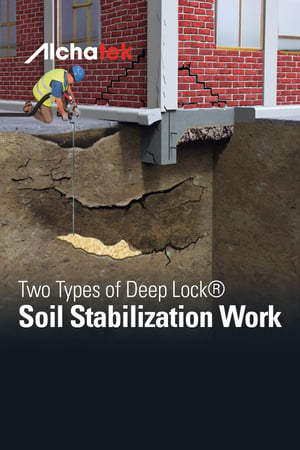

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

Deep Lock® is an innovative process developed by Alchatek that utilizes high-quality structural polymers to address deep soil issues. This powerful, painless, and rapid solution stabilizes soil at all levels, ensuring long-lasting results with minimal disruption to the property. This article profiles the two main types of Deep Lock® soil stabilization work and the specific situations in which each type is most effective.

Essential Details

Essential Details