In Cape Canaveral, Florida, a heavily loaded slap stand structure was planned for construction along a transfer aisle in the Vehicle Assembly Building (VAB). This slap stand would be critical in servicing the proposed Space Launch System vehicle (SLS). However, the project faced a significant challenge when it was discovered that the near-surface subsoils consisted of loose fill materials susceptible to further densification and volume loss due to vibrations and water infiltration. With the slap stand tentatively designed to bear directly upon the ground-level floor slab of the VAB, the degree of subsoil support beneath the floor slab section became a critical concern.

Powerful Polymers

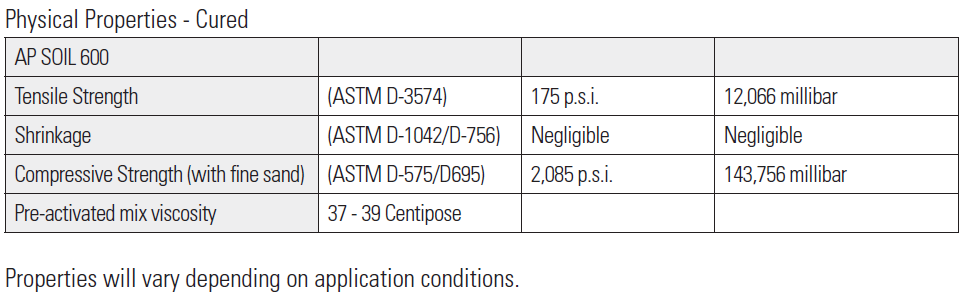

To address this issue, the geotechnical engineer of record recommended a ground improvement solution using permeation grout. Helicon, a leading soil stabilization contractor, worked alongside the geotechnical design team to develop a permeation grout program that would meet the building code load criteria. AP Soil 600, a high-strength, hydro-insensitive structural polyurethane foam, was selected as the ideal product for this project due to its exceptional ability to support heavy structures.

Painless Procedure

Helicon’s technicians installed permeation grout injection pipes on a center-to-center spacing of approximately 2 feet across each of the slap stand areas. The injection points were driven to a depth of at least 5 feet below the floor slab grade. Grout was injected at a relatively low pressure (less than 50 psi), and grout needles were slowly withdrawn during pumping to ensure a uniform distribution of grout to about 3 feet below the bottom of the slab level. The amount of grout used was carefully controlled, with less than 15 gallons per foot per injection point.

Rapid Result

The permeation grout project was a resounding success, effectively improving the load-bearing capacity of the existing soils at the site. The precise application of AP Soil 600 ensured that the slap stand structure would have a stable and reliable foundation, allowing for the safe and efficient servicing of the Space Launch System vehicle. Thanks to Helicon’s expertise and the power AP Soil 600, this piece of critical infrastructure in Cape Canaveral was reinforced and readied for countless future space exploration missions.

Essential Details

Essential Details

Before embarking on any bird bath repair project using the Deep Lock® process, it's crucial to consult with industry specialists. The Alchatek support team, with extensive experience in advanced pavement repair techniques, offers invaluable insights for assessing site conditions, choosing appropriate materials, and implementing effective repair strategies.

Before embarking on any bird bath repair project using the Deep Lock® process, it's crucial to consult with industry specialists. The Alchatek support team, with extensive experience in advanced pavement repair techniques, offers invaluable insights for assessing site conditions, choosing appropriate materials, and implementing effective repair strategies.

In the previous post, the causes and consequences of bird baths in road pavement were explored. Now, attention will turn to an innovative solution for repairing these issues: the Deep Lock® process.

In the previous post, the causes and consequences of bird baths in road pavement were explored. Now, attention will turn to an innovative solution for repairing these issues: the Deep Lock® process.

Have you ever noticed shallow, pond-like formations on the surface of roads, particularly in private neighborhoods, subdivisions, or parking lots? These are known as "bird baths" in the road surface, and they're more than just a quirk of the road. They signify deeper issues in road maintenance and safety that are crucial to address.

Have you ever noticed shallow, pond-like formations on the surface of roads, particularly in private neighborhoods, subdivisions, or parking lots? These are known as "bird baths" in the road surface, and they're more than just a quirk of the road. They signify deeper issues in road maintenance and safety that are crucial to address.

Polyurethane foam can be used in a variety of new construction projects, from road widening to zero lot line excavation projects to a variety of complex excavation and foundation support scenarios. The use of polyurethane stabilization techniques provides clear advantages like cost-effectiveness, strength, and versatility across a wide range of situations. However, properly implementing them requires extensive technical expertise in assessing site conditions, selecting the right materials, and creating effective injection plans.

Polyurethane foam can be used in a variety of new construction projects, from road widening to zero lot line excavation projects to a variety of complex excavation and foundation support scenarios. The use of polyurethane stabilization techniques provides clear advantages like cost-effectiveness, strength, and versatility across a wide range of situations. However, properly implementing them requires extensive technical expertise in assessing site conditions, selecting the right materials, and creating effective injection plans.

In new construction projects, establishing a solid foundation for footings and slabs is crucial, especially in challenging soil conditions. Polyurethane foam offers a groundbreaking approach to improving soil stability, a key factor in the longevity and safety of new structures.

In new construction projects, establishing a solid foundation for footings and slabs is crucial, especially in challenging soil conditions. Polyurethane foam offers a groundbreaking approach to improving soil stability, a key factor in the longevity and safety of new structures.

As construction excavation projects continue to push the boundaries of complexity, innovative solutions are needed to ensure safety and stability. Polyurethane foam has emerged as an indispensable tool for these unique challenges. With a dual capability to stabilize soil and complement traditional retaining methods like sheet piling or secant walls, polyurethane foam provides robust support precisely when and where it is most needed. Whether plugging gaps to prevent infiltration, enhancing structural support, or sealing out soil in deep foundation pits, this versatile material enables advanced excavations that would otherwise be extremely risky if not impossible.

As construction excavation projects continue to push the boundaries of complexity, innovative solutions are needed to ensure safety and stability. Polyurethane foam has emerged as an indispensable tool for these unique challenges. With a dual capability to stabilize soil and complement traditional retaining methods like sheet piling or secant walls, polyurethane foam provides robust support precisely when and where it is most needed. Whether plugging gaps to prevent infiltration, enhancing structural support, or sealing out soil in deep foundation pits, this versatile material enables advanced excavations that would otherwise be extremely risky if not impossible.

Excavating near existing structures, particularly in zero lot line scenarios like building additions, poses unique challenges. Traditional methods like sheet piling, while effective, can cause issues such as adjacent structure disruption, soil settlement, and excessive noise, making them less ideal in dense, urban environments.

Excavating near existing structures, particularly in zero lot line scenarios like building additions, poses unique challenges. Traditional methods like sheet piling, while effective, can cause issues such as adjacent structure disruption, soil settlement, and excessive noise, making them less ideal in dense, urban environments.

Road widening projects, essential for improving traffic flow and infrastructure, traditionally involve digging up and replacing unstable soil. This method, however, poses risks to existing roads and is both costly and time-consuming. The use of polyurethane foam to stabilize existing soil is often more efficient and effective.

Road widening projects, essential for improving traffic flow and infrastructure, traditionally involve digging up and replacing unstable soil. This method, however, poses risks to existing roads and is both costly and time-consuming. The use of polyurethane foam to stabilize existing soil is often more efficient and effective.