Concrete slabs sink for a variety of reasons. The result is an eyesore and possibly a trip hazard that could - in a worst case scenario - result in a serious injury, a law suit and/or death. Lifting slabs with polyurethane foam is safe, fast, and economical.

Concrete slabs sink for a variety of reasons. The result is an eyesore and possibly a trip hazard that could - in a worst case scenario - result in a serious injury, a law suit and/or death. Lifting slabs with polyurethane foam is safe, fast, and economical.

Property owners and managers should learn how to deal with these liability issues NOW with the latest concrete repair techniques and preventative measures. If you’re a contractor, you need this information because it’s critical for YOUR customer – the property owner.

Common Danger Zones

Since an ounce of prevention is worth a pound of cure, it’s helpful to know where to look for potential sunken slabs, especially if you own or manage a large variety of properties. As a contractor you’ll want to focus on these types of sites when looking for potential customers. The three main property categories that tend to have slab settling issues are:

- Residential (single and multi-family).

- Commercial and industrial.

- Warehouse and logistical.

Residential sites can often have driveway, sidewalk, patio, or garage floor issues. Commercial and industrial sites often contain showroom or factory floors made of concrete slab. Warehouse and logistical centers can contain huge floors with massive square footage. Because warehouse floors are often raised off the ground to incorporate a loading dock, they are particularly vulnerable to the formation of dangerous voids underneath.

Causes of Slab Settlement

Let’s take a look at why slabs sink in the first place. There are at least six main reasons:

- Equipment on surface putting too much weight on slabs.

- Erosion due to natural causes.

- Leaking drain pipes and water mains.

- Improper site drainage or poor water management from downspouts and gutters.

- Poor soil consolidation/compaction.

- Old trash pits from the original construction phase that were too close to the structure.

Familiarity with these common causes of slab settling can help a lot when attempting to diagnose the exact cause at a specific location. For more, see our blog post series The Causes of Unstable Soil.

Results of Neglect

After becoming aware of a slab issue, the property owner has a critical choice to make. To repair or not to repair – that is the question. Neglecting a repair can have huge implications. Here are a few possible results of neglect:

- Damage to vehicles and equipment.

- Unlevel racking and storage.

- Personal property damage.

- Sinkholes.

- Trip hazards.

- Employee injuries.

- Limitless liability issues.

Read that list a few times and seriously consider the very real possibility that one or more of these events may occur when a property owner neglects a slab repair. As experts with many years in the industry, we’ve seen every one of these events unfold after a problem was ignored.

In the next installment of this two-part series, we’ll review the two most common methods for repairing a trip hazard aside from polyurethane, and then we’ll review the three most common types of slab repair with polyurethane: slab lifting, soil stabilization and void fill.

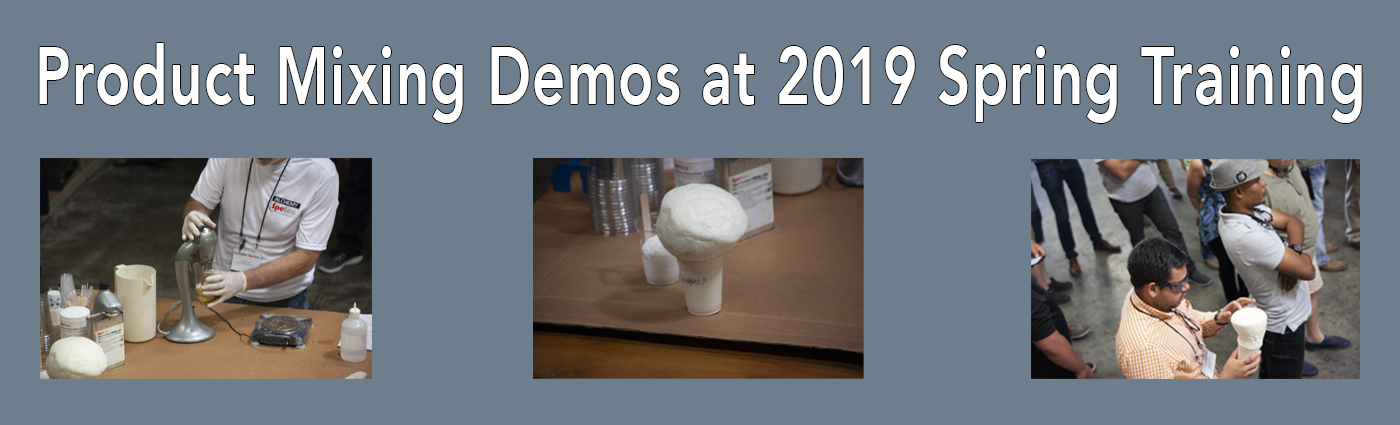

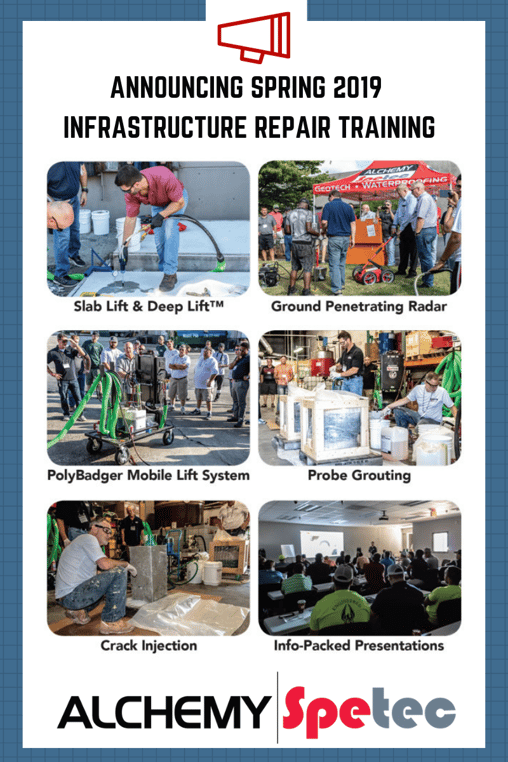

See live product mixing demos!

See live product mixing demos!

Thursday - Leak Seal

Thursday - Leak Seal

In this blog post, we will share some tips for stabilizing soil in cold weather. The two main points to remember are – make sure the ground isn’t frozen and condition your material and equipment properly.

In this blog post, we will share some tips for stabilizing soil in cold weather. The two main points to remember are – make sure the ground isn’t frozen and condition your material and equipment properly.

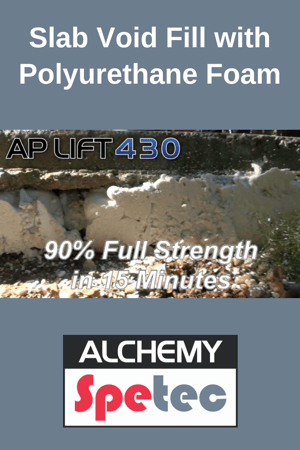

Voids beneath concrete slabs can be filled with two component polymer foam designed to work in wet or dry conditions.

Voids beneath concrete slabs can be filled with two component polymer foam designed to work in wet or dry conditions.