Alchemy-Spetec is already known for providing the most powerful polymers and painless procedures contractors need to achieve the rapid results their projects demand.

However, on construction projects of almost any scope and size, ensuring the safety of public drinking water is also mission-critical. That's why the following Alchemy-Spetec' polyurethane resin products have received the official NSF seal of approval for contact with drinking water:

AP Lift 430

AP Lift 475

AP Soil 600

AP Fill 700

Spetec PUR H100

Spetec PUR H200

Spetec PUR F400

Spetec PUR GT500

Spetec PUR HighFoamer

Spetec AG200

This single designation ensures compliance with the Safe Water Drinking Act (SDWA) and guarantees peace of mind for in-the-field stakeholders on construction projects of almost any scope and size.

The SDWA helps ensure the water we drink, bathe in, cook with, and use in myriad other ways in daily life is safe for consumption. The federal law was put in place to maintain public health standards for drinking water systems. It defines what is considered a contaminant – both man-made and naturally occurring; and outlines the agencies responsible for regulating, monitoring, and enforcing adherence to the law, primarily the Environmental Protection Agency.

The SDWA gives the EPA latitude to impose criminal and civil penalties on industries not in compliance. In 2014 enforcement efforts policing clean water netted $163 million in penalties and fines, 155 combined years of incarceration for sentenced defendants, and $16 million in court-ordered project clean-ups.

Because so many of those defined contaminants are pertinent to even the most basic construction projects – turbidity from soil runoff, leaching from PVC pipes, potentially harmful and corrosive chemicals, and more – understanding and adhering to the law is particularly important for industry stakeholders. Contractors and engineers must be able to confidently choose vendors whose products and services won’t become the source or cause of drinking water contamination either in the short or long-term. NSF certification offers assurance that such problems won’t occur or will, at a minimum, be addressed.

“NSF, an independent, private, not-for-profit, third-party certification organization founded in 1944, has developed numerous health-based certification programs and consensus standards including those that relate to drinking water,” reads an NSF compliance brief. “The purpose of its certification program is to promote public health and enrich the quality of life. Through its Council of Public Health and Health Advisory Board, which includes EPA health professionals, it obtains guidance in developing and maintaining programs and standards. NSF also partners with code councils to ensure ongoing compliance.”

The products Alchemy-Spetec offers that can help net the most reliable and cost-effective results for contractors. NSF-certified products and materials are evaluated and lab-tested, and production facilities such as our own are inspected and annually audited for re-testing to maintain certification.

Alchemy-Spetec voluntarily undergoing such a rigorous certification process is invaluable to customers because it provides assurance that, at the end of the day, our arsenal of products are not only the top-performers in the market, but also protectors of the environment. Powerful polymers, painless procedures, rapid results!

Want in-depth info on Alchemy-Spetec products?

Voids beneath concrete slabs can be filled with two component polymer foam designed to work in wet or dry conditions. AP Lift 430 foam can support up to 7,200 lbs per square foot and will cure to 90% full strength in 15 minutes. (Of the most resilient concrete slab jacking foams, AP Lift 430 is proven to lift concrete slabs under harsh conditions. This two-component, high-strength, high-density, hydro-insensitive structural polyurethane foam is the top slab jacking solution for concrete slab foundation repair, soil stabilization, and compaction grouting. AP Lift 430 weighs 2.75 – 3.25 pounds per cubic foot.)

Voids beneath concrete slabs can be filled with two component polymer foam designed to work in wet or dry conditions. AP Lift 430 foam can support up to 7,200 lbs per square foot and will cure to 90% full strength in 15 minutes. (Of the most resilient concrete slab jacking foams, AP Lift 430 is proven to lift concrete slabs under harsh conditions. This two-component, high-strength, high-density, hydro-insensitive structural polyurethane foam is the top slab jacking solution for concrete slab foundation repair, soil stabilization, and compaction grouting. AP Lift 430 weighs 2.75 – 3.25 pounds per cubic foot.)

One of the hidden dangers a warehouse or industrial property owner and their employees can face is an unstable or sunken slab with a large void underneath. The last thing anyone wants is injury and/or a lawsuit resulting from an un-repaired trip hazard or worse - a complete slab collapse. Take a good long look at the photo in today's blog graphic. This occurred when a forklift carrying a heavy piece of equipment crossed a slab with an un-detected void underneath. Luckily, no one was injured.

One of the hidden dangers a warehouse or industrial property owner and their employees can face is an unstable or sunken slab with a large void underneath. The last thing anyone wants is injury and/or a lawsuit resulting from an un-repaired trip hazard or worse - a complete slab collapse. Take a good long look at the photo in today's blog graphic. This occurred when a forklift carrying a heavy piece of equipment crossed a slab with an un-detected void underneath. Luckily, no one was injured.

Powerful Polymer

Powerful Polymer

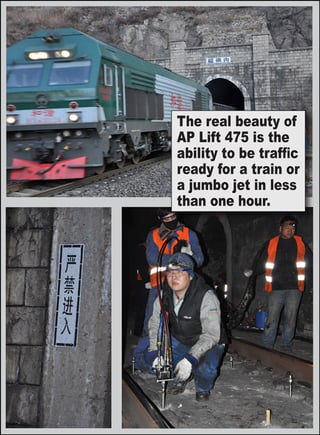

County inspectors found a depression in the road due to an underground sewer line that wasn’t sealed at a heavily trafficked roadway intersection in Orange County, Florida. Water and eroding soil were infiltrating the sewer line causing the road to slowly settle. The resulting voids around the drainage structures had the potential to grow larger, eventually resulting in a complete cave-in of the roadway. In this particular case, there was a patch of asphalt 12’ x 25’ that was settling and officials feared a cave-in would occur. A point repair was done from within the leaky pipe to stop the infiltration but they feared it was only a matter of time before the road gave way. It was going to be very difficult and inconvenient to dig up this roadway, fill the void, re-compact, and re-pave due to the high volume of traffic, the adjoining rail crossing, as well as several major utilities running through the area. Not to mention that the area would have to be completely shut down to accommodate all of the equipment required for such a repair.

County inspectors found a depression in the road due to an underground sewer line that wasn’t sealed at a heavily trafficked roadway intersection in Orange County, Florida. Water and eroding soil were infiltrating the sewer line causing the road to slowly settle. The resulting voids around the drainage structures had the potential to grow larger, eventually resulting in a complete cave-in of the roadway. In this particular case, there was a patch of asphalt 12’ x 25’ that was settling and officials feared a cave-in would occur. A point repair was done from within the leaky pipe to stop the infiltration but they feared it was only a matter of time before the road gave way. It was going to be very difficult and inconvenient to dig up this roadway, fill the void, re-compact, and re-pave due to the high volume of traffic, the adjoining rail crossing, as well as several major utilities running through the area. Not to mention that the area would have to be completely shut down to accommodate all of the equipment required for such a repair.

Alchemy-Spetec products will now officially be promoted under the Leak Seal and Geotech lines. As holds true with most mergers (Alchemy Polymers and Spetec formed Alchemy-Spetec in 2017), the integration of products and services can take time. This rebrand will be reflected in two separate product catalogs. One for Leak Seal products and one for Geotech products. We are confident that the two-catalog offering is the best solution for our partners and customers.

Alchemy-Spetec products will now officially be promoted under the Leak Seal and Geotech lines. As holds true with most mergers (Alchemy Polymers and Spetec formed Alchemy-Spetec in 2017), the integration of products and services can take time. This rebrand will be reflected in two separate product catalogs. One for Leak Seal products and one for Geotech products. We are confident that the two-catalog offering is the best solution for our partners and customers.