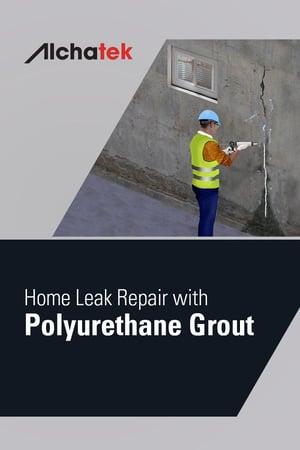

Concrete leak repair is crucial for homeowners with leaks in basements or other below-grade spaces. Concrete can deteriorate over time due to imperfect construction, weather, wear, and unstable soil. However, effective solutions are available. This article explains how polyurethane leak seal grouts offer a cost-effective, durable fix for waterproofing your home.

Concrete leak repair is crucial for homeowners with leaks in basements or other below-grade spaces. Concrete can deteriorate over time due to imperfect construction, weather, wear, and unstable soil. However, effective solutions are available. This article explains how polyurethane leak seal grouts offer a cost-effective, durable fix for waterproofing your home.

The Problem with Standard Concrete Leak Repair Methods

Many homeowners initially try using sump pumps or hydraulic cement to remedy leaks. While these may provide a band-aid, they don't get to the root of the problem. Sump pumps only remove leaking water after it has already infiltrated. Hydraulic cement may temporarily stop the leak, but it is a rigid negative side bandied and thus prone to cracking as a structure shifts and settles.

The Benefits of Polyurethane Concrete Leak Repair

In contrast, experienced leak seal specialists rely on polyurethane grouts to stop leaks at their source. They inject this material into leaking cracks and joints. The grouts then react with water to form a flexible, watertight seal. Even as a structure naturally moves, the seal stays intact. Furthermore, polyurethane grouts provide industrial-grade strength while remaining safe for residential use.

The Importance of Professional Application

While injecting polyurethane grouts may sound simple, skilled professionals should handle it. Contractors undergo training to properly drill injection holes, prepare the components, and apply the product for maximum effectiveness. An expert will ensure the grout fully penetrates the leaks and forms a reliable, long-term seal.

Environmentally-Friendly Leak Repair

When selecting a contractor, look for one that uses NSF/ANSI/CAN 61 certified products. For example, most of Alchatek's leak seal grouts are NSF-certified to meet strict environmental standards. NSF certification involves both initial and ongoing testing, so you can trust these products always to be eco-friendly.

Key Takeaways

Concrete leak repair doesn't have to be a daunting task. Armed with the right products and expertise, a skilled contractor can provide an effective, long-lasting solution. When you choose a professional specializing in polyurethane leak seal grouts, you'll gain an ally in protecting your home against water intrusion.

Fill out this form or call 404-618-0438 for a contractor referral today!

Construction and building maintenance rely on effective waterproofing to ensure longevity and structural integrity. In fact, waterproofing protects against water damage and moisture-related structural issues in residential homes, commercial buildings, and infrastructure projects. Positive side waterproofing and negative side waterproofing are two different methods that are used based on factors like construction design, budget, and water exposure.

Construction and building maintenance rely on effective waterproofing to ensure longevity and structural integrity. In fact, waterproofing protects against water damage and moisture-related structural issues in residential homes, commercial buildings, and infrastructure projects. Positive side waterproofing and negative side waterproofing are two different methods that are used based on factors like construction design, budget, and water exposure.

If you're a homeowner dealing with concrete leaks in your basement or below-grade living spaces, it's essential to hire an expert who specializes in polyurethane leak seal grouts. These advanced products offer a cost-effective, durable solution for waterproofing your home. Moreover, a skilled contractor will ensure that your home leak repair job is done right.

If you're a homeowner dealing with concrete leaks in your basement or below-grade living spaces, it's essential to hire an expert who specializes in polyurethane leak seal grouts. These advanced products offer a cost-effective, durable solution for waterproofing your home. Moreover, a skilled contractor will ensure that your home leak repair job is done right.

Essential Details

Essential Details

Essential Details

Essential Details

Addressing the complexities of coating failure requires more than just a superficial understanding of the issue. It necessitates a deep dive into the technical aspects and an experienced partner to guide the process.

Addressing the complexities of coating failure requires more than just a superficial understanding of the issue. It necessitates a deep dive into the technical aspects and an experienced partner to guide the process.

In the field of coating failure solutions, curtain grouting with polyurethane is very effective, especially in scenarios where water intrusion is a primary concern. Curtain grouting is an effective method that not only addresses existing coating failures but also acts as a preventive measure.

In the field of coating failure solutions, curtain grouting with polyurethane is very effective, especially in scenarios where water intrusion is a primary concern. Curtain grouting is an effective method that not only addresses existing coating failures but also acts as a preventive measure.

Coatings are more than just a cosmetic layer on a structure; they play a vital role in protecting buildings from various environmental factors. Essentially, a coating is a layer of material applied to the surface of an object, intended to protect, decorate, or add functionality. In terms of structural integrity, coatings serve as a barrier against moisture, chemicals, UV radiation, and mechanical wear. They prevent corrosion, enhance durability, and ensure that the underlying material, such as concrete, metal, or wood, remains unharmed by external elements.

Coatings are more than just a cosmetic layer on a structure; they play a vital role in protecting buildings from various environmental factors. Essentially, a coating is a layer of material applied to the surface of an object, intended to protect, decorate, or add functionality. In terms of structural integrity, coatings serve as a barrier against moisture, chemicals, UV radiation, and mechanical wear. They prevent corrosion, enhance durability, and ensure that the underlying material, such as concrete, metal, or wood, remains unharmed by external elements.

Maintaining irrigation canals effectively is a complex task that often requires specialized knowledge and skills. While do-it-yourself approaches can be useful for minor issues, more intricate challenges in canal maintenance typically necessitate professional input.

Maintaining irrigation canals effectively is a complex task that often requires specialized knowledge and skills. While do-it-yourself approaches can be useful for minor issues, more intricate challenges in canal maintenance typically necessitate professional input.

Concrete-lined canals are a cornerstone of modern irrigation infrastructure, designed for efficient water conveyance. However, one of the challenges faced with these systems is leaking panel joints. These joints, where concrete panels meet, can become vulnerable points, undermining the efficiency of the canal, and leading to water loss. Sealing these leaks is crucial for maintaining the structural integrity and operational efficacy of lined canals.

Concrete-lined canals are a cornerstone of modern irrigation infrastructure, designed for efficient water conveyance. However, one of the challenges faced with these systems is leaking panel joints. These joints, where concrete panels meet, can become vulnerable points, undermining the efficiency of the canal, and leading to water loss. Sealing these leaks is crucial for maintaining the structural integrity and operational efficacy of lined canals.