The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.

The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.

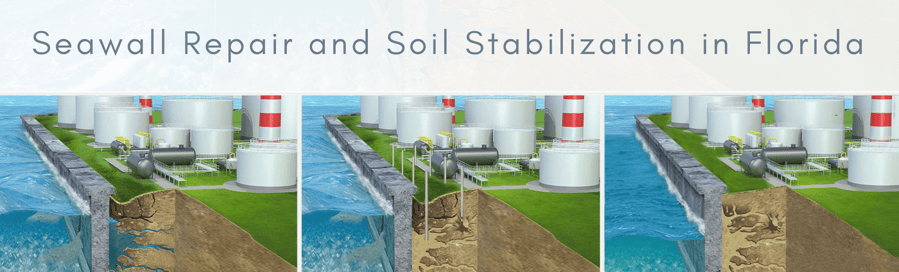

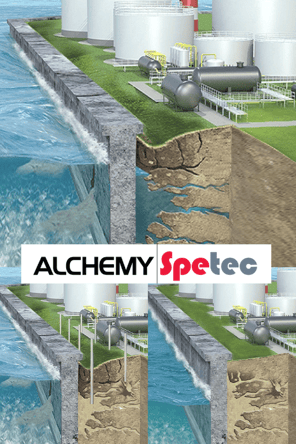

After the storms, of course, there was a flood of phone calls to both Alchemy-Spetec headquarters and to our contractor network. Homeowners and businesses on the water suffered catastrophic damage to their seawalls and bulkheads. The city of Punta Gorda, FL alone lost over 9 miles of seawall with another 17 miles damaged. The bright spot of all this was what we discovered when we inspected seawalls that had been grouted with polyurethane. These particular seawalls held up remarkably well.

Here’s what we learned in the aftermath:

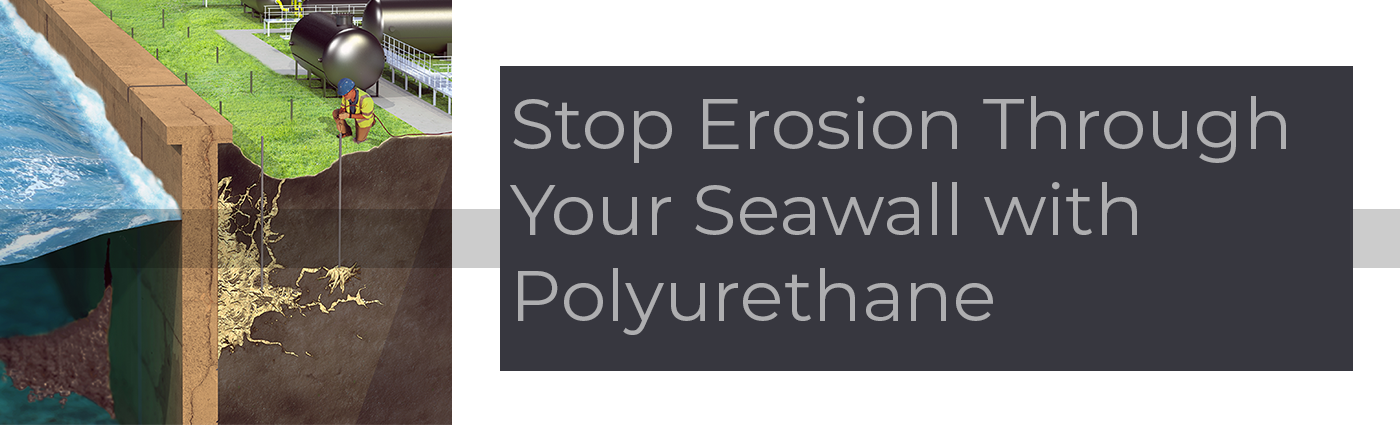

Many people that live or work on the water often observe sinkholes that develop on the landward side of the seawall. Tides, wakes, and heavy rain events create hydrostatic pressure that is constantly trying to equalize on both sides of the wall. If water behind the wall cannot relieve itself through drains or weep holes, it will force its way beneath the wall carrying soil with it. This is called “piping”. Over time these pathways will funnel more and more soil out from behind the wall, creating sinkholes and dangerous voids.

Last year, especially with Irma, the eye of the hurricane was off the west coast of Florida and it created a

huge sucking action. You probably saw footage of Tampa Bay being emptied by the suction. At the

same time, all those seawalls and bulkheads with the voids and the piping experienced panel rotation.

That is what happens when the upper part of the wall remains secured with a deadman or tieback, and

the lower portion of the wall blows out. After that it is game over for the wall and the entire property is

in jeopardy.

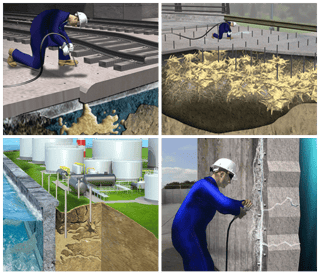

When contractors inject a seawall with Alchemy-Spetec polyurethane, they drive injection probes several feet below the toe of the wall. Permeation and void filling resins like AP Fill 700 penetrate sandy soil, plug up voids or piping pathways, and stop the loss of soil from behind the wall. We are literally building the seawall down instead of up, and it works!

If you have made a decision to live or locate your business beside the water, then you know too well the

risks. Consider having an Alchemy-Spetec certified contractor come by and evaluate your current seawall

condition. Remember, once a wall fails the entire property is at risk of being lost. I know adding a

couple more feet to the seawall cap is real popular these days but consider building it down this year

instead.

Want more information on Alchemy-Spetec seawall products?

Repair sea walls instead of replacing them by stopping high flow leaks, filling the voids behind concrete structures and binding loose soil with:

Repair sea walls instead of replacing them by stopping high flow leaks, filling the voids behind concrete structures and binding loose soil with:

When it comes to seawalls, there is a lot more to learn than meets the eye. A seawall is like a living, breathing thing: especially in the way that it is designed to function. But like all living breathing things, they have a finite lifespan. For many of them, it's a mere 20 – 30 years. Depending on where you live, replacing a seawall can cost anywhere from $150 to $500 per foot. That's enough for some homeowners to choose to move instead of rebuilding their seawalls. Today however, signs of seawall distress can be solved before they get too bad through the application of polyurethane grouts to seal leaks, fill voids, and stabilize the surrounding soils.

When it comes to seawalls, there is a lot more to learn than meets the eye. A seawall is like a living, breathing thing: especially in the way that it is designed to function. But like all living breathing things, they have a finite lifespan. For many of them, it's a mere 20 – 30 years. Depending on where you live, replacing a seawall can cost anywhere from $150 to $500 per foot. That's enough for some homeowners to choose to move instead of rebuilding their seawalls. Today however, signs of seawall distress can be solved before they get too bad through the application of polyurethane grouts to seal leaks, fill voids, and stabilize the surrounding soils.

The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.

The month of June kicks off hurricane season and the forecasters are calling for a higher than normal level of activity (don’t they always?). Last year I posted a blog noting hurricane season arriving and I had no idea how prophetic it would turn out to be. 2017 brought some of the worst hurricane damage in years to the United States.-1.png?width=1024&name=Polyurethane%20Soil%20Stabilization%20Explained-banner%20(1)-1.png)

.png?width=320&name=Seawall%20Repair-blog%20(1).png) The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product,

The product our contractors use to stop this soil loss is a permeation resin designed to penetrate loose soil zones, bind it all together, and stop further loss. This product,

.png?width=320&name=Residential%20Seawall%20Repair-blog%20(1).png) But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

But one challenge many oceanfront home owners eventually find themselves facing is leaking seawalls. You depend on seawalls to keep water on the outside and the the soil that supports your property on the inside.

Higher Budgets/Larger Areas Needing Repair

Higher Budgets/Larger Areas Needing Repair In this post, I will provide a brief overview of Alchemy-Spetec's

In this post, I will provide a brief overview of Alchemy-Spetec's

As the end of the year approaches, it feels appropriate to take a look back at some the most popular Alchemy Polymers blog posts. A quick look at the stats on the day I write this article reveals the top posts to be

As the end of the year approaches, it feels appropriate to take a look back at some the most popular Alchemy Polymers blog posts. A quick look at the stats on the day I write this article reveals the top posts to be