A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when Bay Area Underpinning entered the scene. Together with Alchatek, they presented an alternative solution: Deep Lock® soil stabilization and concrete leveling. After careful consideration, the DOT engineers agreed to try this innovative approach. This method promised to minimize traffic disruption and significantly reduce costs compared to full replacement, which would have required closing the entire roadway and replacing a 40x12 foot area of asphalt and sleeper slab.

A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when Bay Area Underpinning entered the scene. Together with Alchatek, they presented an alternative solution: Deep Lock® soil stabilization and concrete leveling. After careful consideration, the DOT engineers agreed to try this innovative approach. This method promised to minimize traffic disruption and significantly reduce costs compared to full replacement, which would have required closing the entire roadway and replacing a 40x12 foot area of asphalt and sleeper slab.

Powerful Polymers

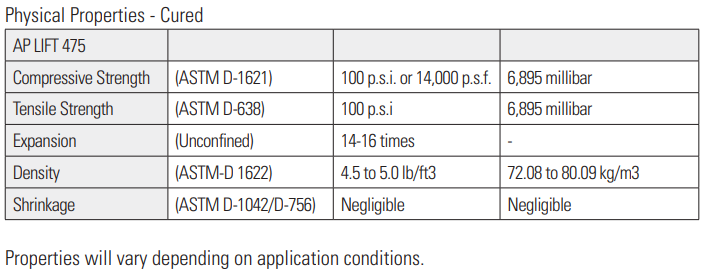

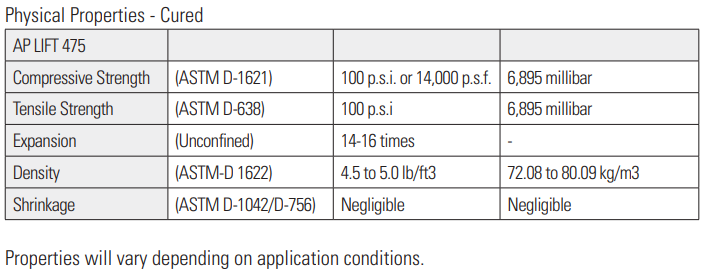

The project team chose AP Lift 475 as the repair material. This substance offers impressive compressive strength while maintaining good expansion properties. Once injected, the material spreads out effectively, filling voids in the annular space within the soil. This combination of strength and expansion makes AP Lift 475 ideal for stabilizing and leveling the settled bridge approach slab. The material's ability to penetrate and fill voids addresses the underlying cause of the settlement, providing a more comprehensive solution than - for example - simply adding a new surface layer.

Painless Procedures

Before starting the repair, DOT engineers conducted thorough soil testing. They performed soil borings to determine soil types and characteristics at various depths. This crucial step provided insights into the subsurface conditions contributing to the settlement. Additionally, they used a DCP (Dynamic Cone Penetrometer) test to identify areas of weak soil density. Armed with this information, the contractor developed an optimal application plan.

The team installed injection tubes on four-foot centers at six- and 10-foot depths. They injected about 40 pounds of material per tube, using 10-15-second shots. This measured approach allowed for controlled material distribution. Throughout the process, the team carefully monitored the slab lift using a rotary laser and zip-level altimeter. These precise instruments ensured even raising of the slab to the desired level, preventing any potential issues from uneven lifting.

Rapid Results

The modular approach to repair minimized traffic disruption, a critical factor for this busy thoroughfare. At any given time, only two out of four lanes remained closed. Consequently, traffic continued to flow throughout the project, preventing gridlock in the area. The team completed the entire leveling process in just four eight-hour shifts, a remarkably short timeframe for such a significant repair. Compared to full replacement, the method significantly cut labor requirements, traffic disruption, and financial costs. Moreover, the repair addressed the root cause of the problem by stabilizing the eroded soil beneath the roadway.

Unlike simply adding an asphalt layer for leveling, which would have provided only a temporary fix, this solution offers long-lasting results. By directly treating the underlying issue, the team greatly reduced the likelihood of recurrence. The success of this project offers a blueprint for similar infrastructure challenges. It showcases how modern materials and techniques can provide cost-effective, efficient, and durable solutions to complex engineering problems.

Want more information on Deep Lock® soil stabilization and slab lifting?

The PX-7 incorporates a valving rod to mechanically purge the mixed material from the mixing module at the end of each shot; eliminates the need for solvent flushing or air purge. It comes standard with a precision machined coupling block made from high strength steel. Manufactured by Polyurethane Machinery Corporation.

The PX-7 incorporates a valving rod to mechanically purge the mixed material from the mixing module at the end of each shot; eliminates the need for solvent flushing or air purge. It comes standard with a precision machined coupling block made from high strength steel. Manufactured by Polyurethane Machinery Corporation.

Suburban Basement

Suburban Basement

The owner of a gas manufacturing facility contacted a Georgia-based contractor regarding significant floor settlement issues, with a warehouse slab dropping approximately 3-4 inches. The settlement made issues for the forklift traversing in and out of the warehouse and posed a risk to the workers.

The owner of a gas manufacturing facility contacted a Georgia-based contractor regarding significant floor settlement issues, with a warehouse slab dropping approximately 3-4 inches. The settlement made issues for the forklift traversing in and out of the warehouse and posed a risk to the workers.

Essential Details

Essential Details

A concrete staircase in a prominent mixed-use complex in Atlanta needed urgent repairs due to a set of 75-foot-long sunken steps. This issue posed a significant trip hazard, potentially compromising visitor safety. The problem stemmed from a combination of factors working together over time. Water infiltration through expansion cracks had created voids beneath the stairs, weakening their foundation. Compounding this issue was the natural tendency of separate concrete pieces to expand and contract, moving independently. This movement was particularly problematic as it caused the steps to separate from the adjacent sidewalk. Over time, the repeated cycles of expansion and contraction, coupled with the underlying voids, led to the steps sinking and rolling, creating a hazardous situation.

A concrete staircase in a prominent mixed-use complex in Atlanta needed urgent repairs due to a set of 75-foot-long sunken steps. This issue posed a significant trip hazard, potentially compromising visitor safety. The problem stemmed from a combination of factors working together over time. Water infiltration through expansion cracks had created voids beneath the stairs, weakening their foundation. Compounding this issue was the natural tendency of separate concrete pieces to expand and contract, moving independently. This movement was particularly problematic as it caused the steps to separate from the adjacent sidewalk. Over time, the repeated cycles of expansion and contraction, coupled with the underlying voids, led to the steps sinking and rolling, creating a hazardous situation.

Essential Details

Essential Details

Are you a geotechnical contractor facing challenges with unreliable lifting foam that leads to costly callbacks? You can significantly reduce these issues by choosing quality lifting foam from a manufacturer focused on slab lifting applications. The right solution makes all the difference in achieving consistent, successful results.

Are you a geotechnical contractor facing challenges with unreliable lifting foam that leads to costly callbacks? You can significantly reduce these issues by choosing quality lifting foam from a manufacturer focused on slab lifting applications. The right solution makes all the difference in achieving consistent, successful results.

Winter weather creates unique challenges for polyurethane slab lifting operations. As temperatures drop, proper equipment care becomes essential for successful projects. Here are vital tips to keep your rig running smoothly during cold weather and properly stored at season's end.

Winter weather creates unique challenges for polyurethane slab lifting operations. As temperatures drop, proper equipment care becomes essential for successful projects. Here are vital tips to keep your rig running smoothly during cold weather and properly stored at season's end.

A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when

A critical infrastructure issue emerged on a four-lane road near downtown San Francisco. Soil erosion caused a bridge approach slab to settle 2.5 to 3 inches over time. The affected area had an asphalt surface with a thin sleeper slab underneath. California Department of Transportation (Caltrans) engineers initially advocated for complete replacement. The situation changed when